Method of rasing wearability of mechanical element

A technology of mechanical parts and wear resistance, which is applied in the field of manufacturing and processing of easy-to-wear mechanical parts. It can solve the problems of limited surface hardness of engineering materials, loss of protection of mechanical parts, and reduced effectiveness of mechanical parts, so as to achieve reliable performance and low cost. , processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

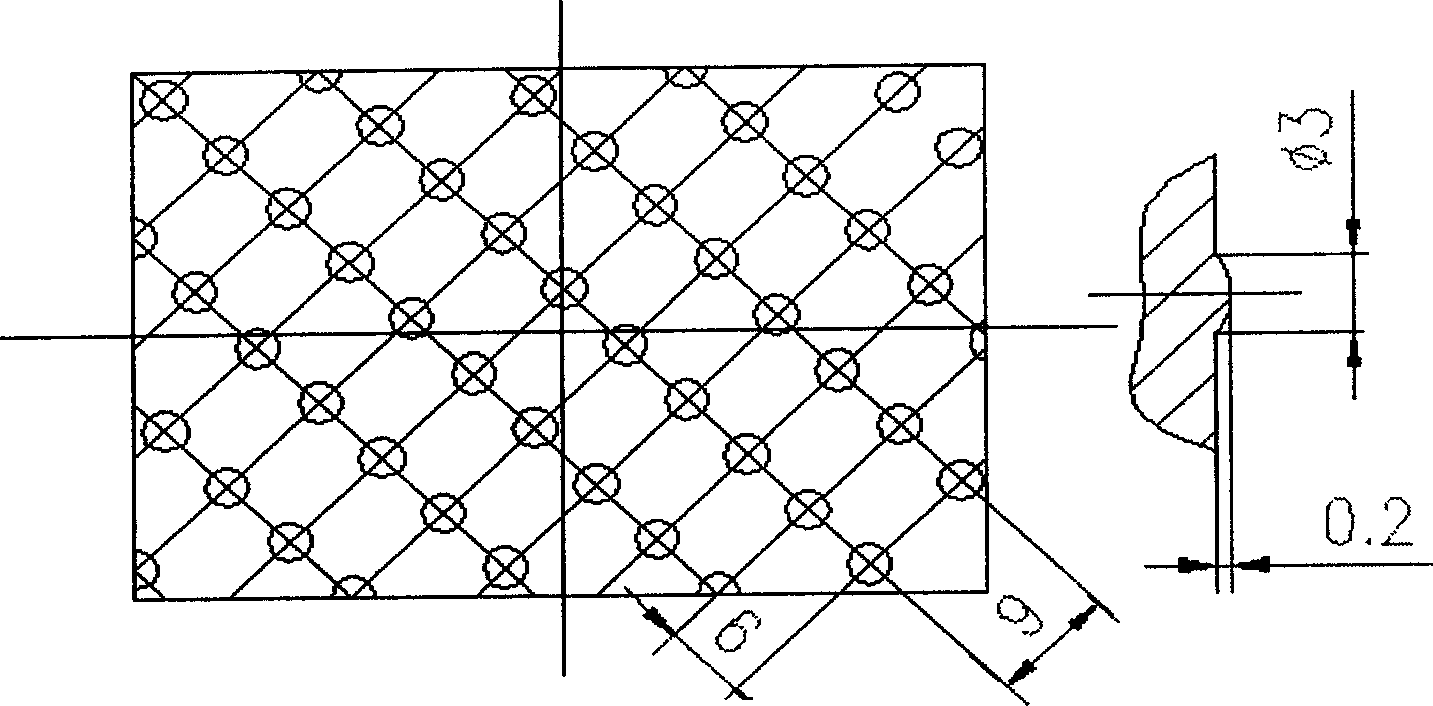

[0020] Manufacture of die-casting machine parts with spherical crowns on the surface - punches. refer to figure 1 , the distribution form of the convex units of the spherical crown is: the diameter of the spherical crown bottom circle is 3 mm, the height of the spherical crown is 0.1 mm, and the spherical crown units are distributed in a rectangular lattice with a center distance of 6 to 9 mm. And the rectangle edge of the lattice is at a 45° angle to the axis of the component, the material is QT600~2, the hardness of the component matrix is HB190~210, and the hardness of the spherical crown convex unit after treatment is HB420~450; the auxiliary cylinder liner is surface infiltration Nitrogen treatment, hardness HB470-500. The ratio of the sum of the projected area of the spherical cap unit on the surface to the surface area is 32.7%. The parts treated with the bionic non-smooth surface and the untreated parts work under the same conditions, and the service life of the m...

Embodiment 2

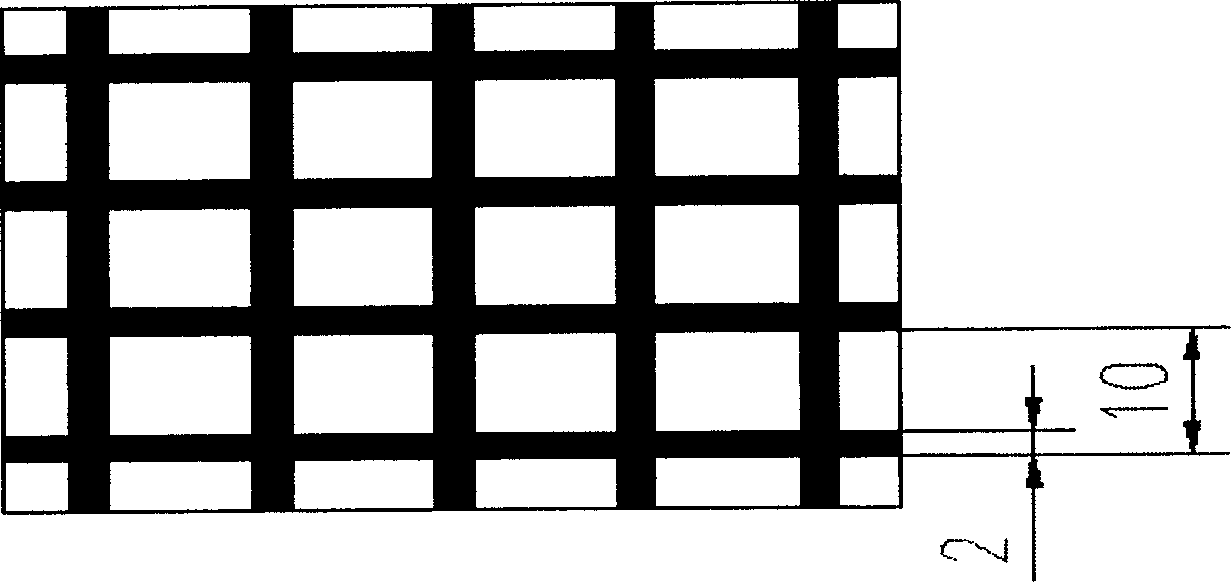

[0022] Manufacture die-casting machine parts with grid-like protrusions on the surface - punches. refer to figure 2 , the grid-like non-smooth shape can be regarded as a strip-shaped convex unit composed of multiple spherical caps. The non-smooth surface is composed of grid-like units with a grid width of d=2mm and a grid height of h=0.15mm. The grid units are arranged in a square with a grid spacing of 10mm (calculated from the center). The material is QT600-2, the hardness of the ductile iron itself is HB190-210; the hardness of the grid unit after treatment is HB420-450; the auxiliary cylinder liner is surface nitriding treatment, and the hardness is HB470-500. The ratio of the sum of the projected area of the grid unit body on the surface to the surface area is 25.6%. The parts treated with bionic non-smooth surface and the untreated parts work under the same conditions, and the service life of the auxiliary cylinder liners is the same. The coefficient is reduced by 2...

Embodiment 3

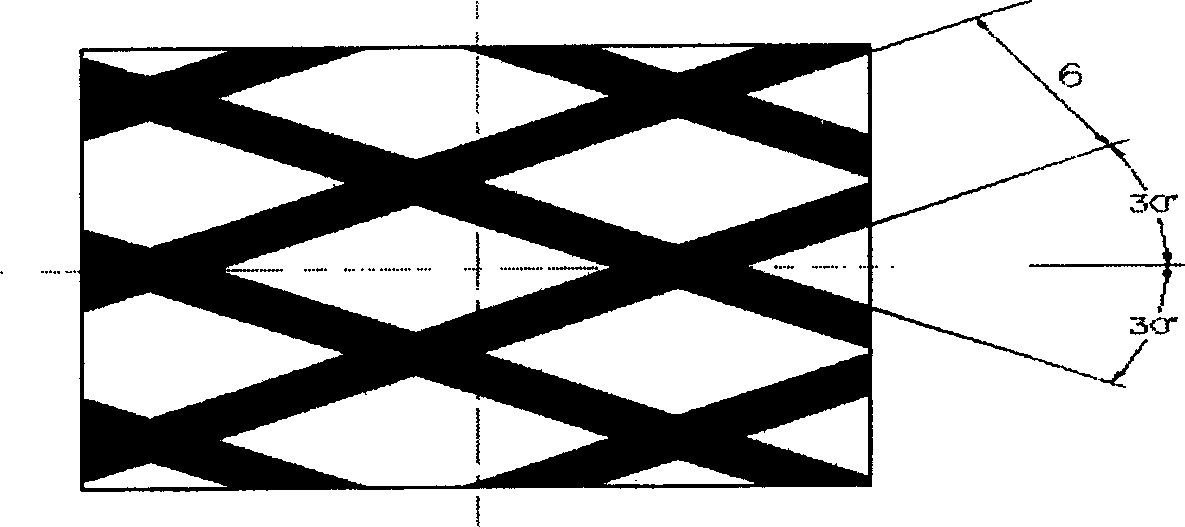

[0024] The manufacturing surface has another kind of grid-like raised die-casting machine part - the punch. refer to image 3 , the design method can design the grid-like non-smooth shape into a diamond shape, the grid width is d=2mm, the grid height is h=0.15mm, the grid spacing is 6mm (calculated based on the center), and the material is QT600-2. The hardness of the ductile iron itself is HB190-210; the hardness of the mesh unit after treatment is HB370-400; the auxiliary cylinder liner is surface nitriding treatment, HB450-490. The ratio of the sum of the projected area of the mesh unit body on the surface to the surface area is 35.9%. The parts treated with bionic non-smooth surface and the untreated parts work under the same conditions, and the service life of the matching and auxiliary cylinder liners is the same. The coefficient was reduced by 23%, while the lifetime of parts with biomimetic non-smooth surfaces was 5.1 times that of untreated parts. 14% higher cost ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com