Automatic bread maker and bread prodn. method

A production method and bread machine technology, applied in the direction of dough mixer, dough preparation, dough processing, etc., can solve the problems of small bread swelling, inappropriateness, difficult formation of gluten, etc., and achieve the effect of simplifying the process and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

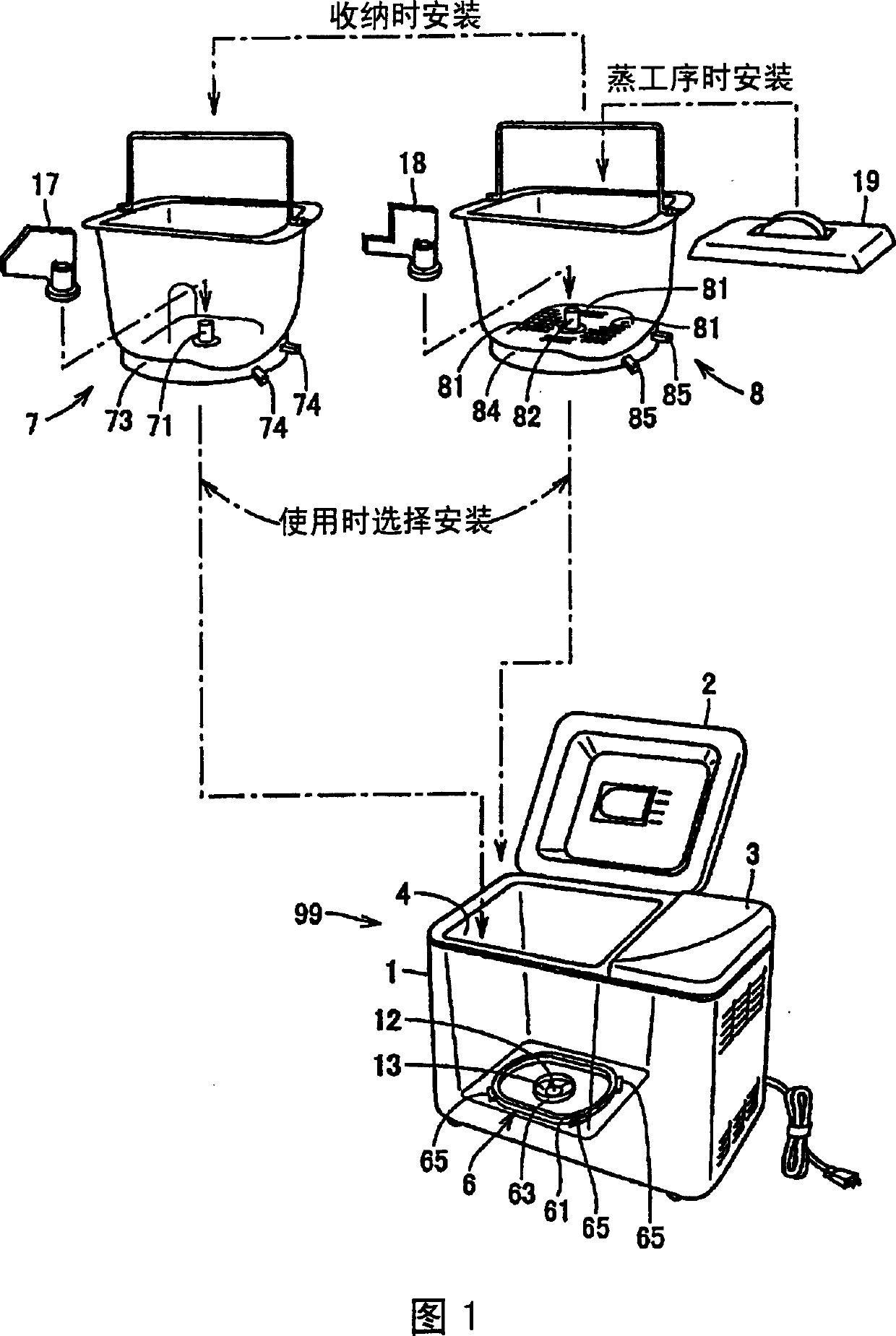

[0043] An automatic bread maker according to an embodiment of the present invention will be described below with reference to the accompanying drawings. Fig. 1 is a perspective view showing the appearance of an automatic bread maker.

[0044]The automatic bread maker 99 includes a housing 1, an opening and closing cover 2, an operation display panel 3, a baking tank 4, a baking heater 5, a boiler 6 which is a steam generating part, and two types of production containers called hoppers. 7 , 8 , motor 9 , power transmission unit 10 and control unit 11 . Two kinds of production containers 7 and 8 can be detachably installed in the baking tank 4 from above the boiler 6 . The making container 7 is used when making bread. The making container 8 is used when making rice cakes or steaming.

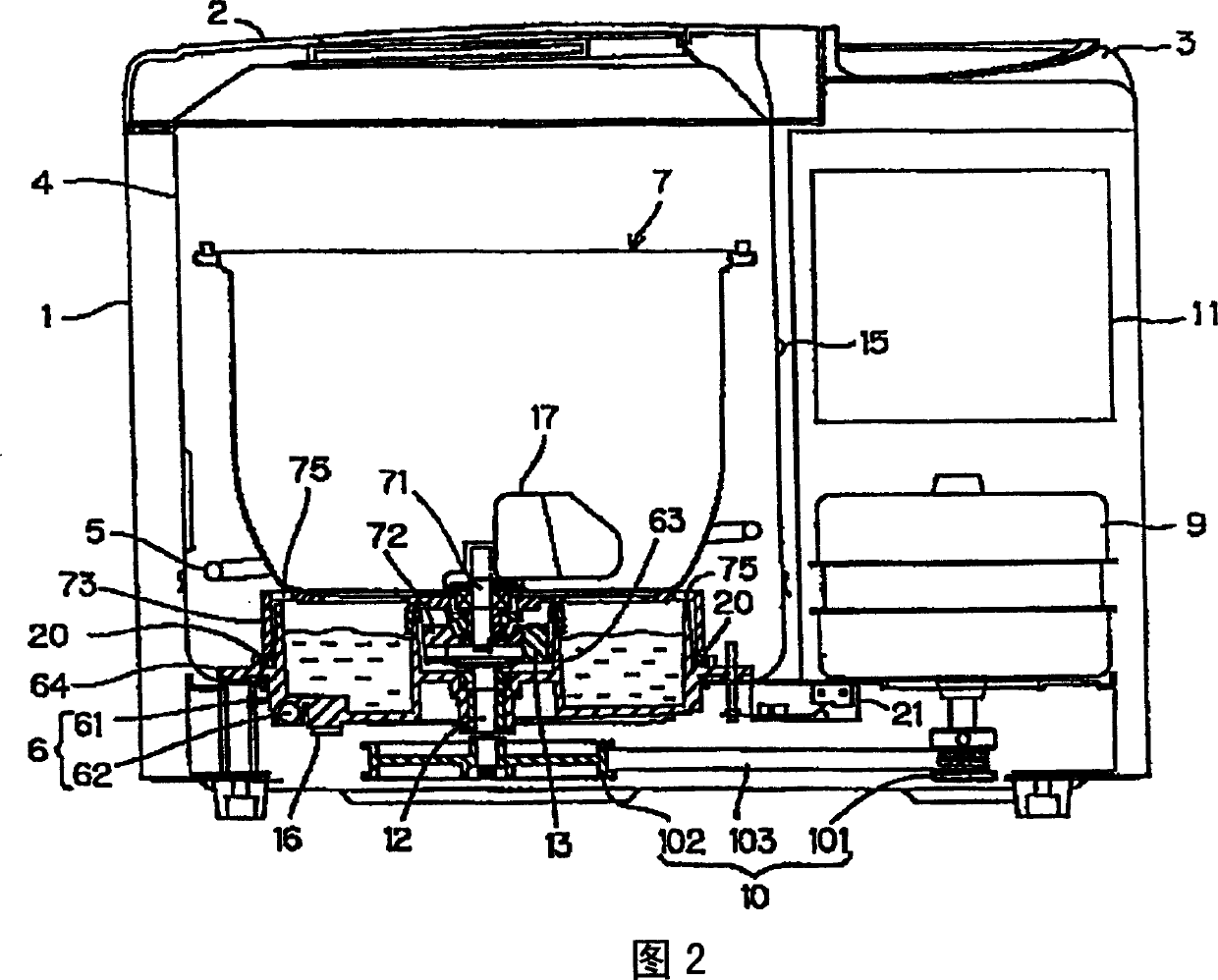

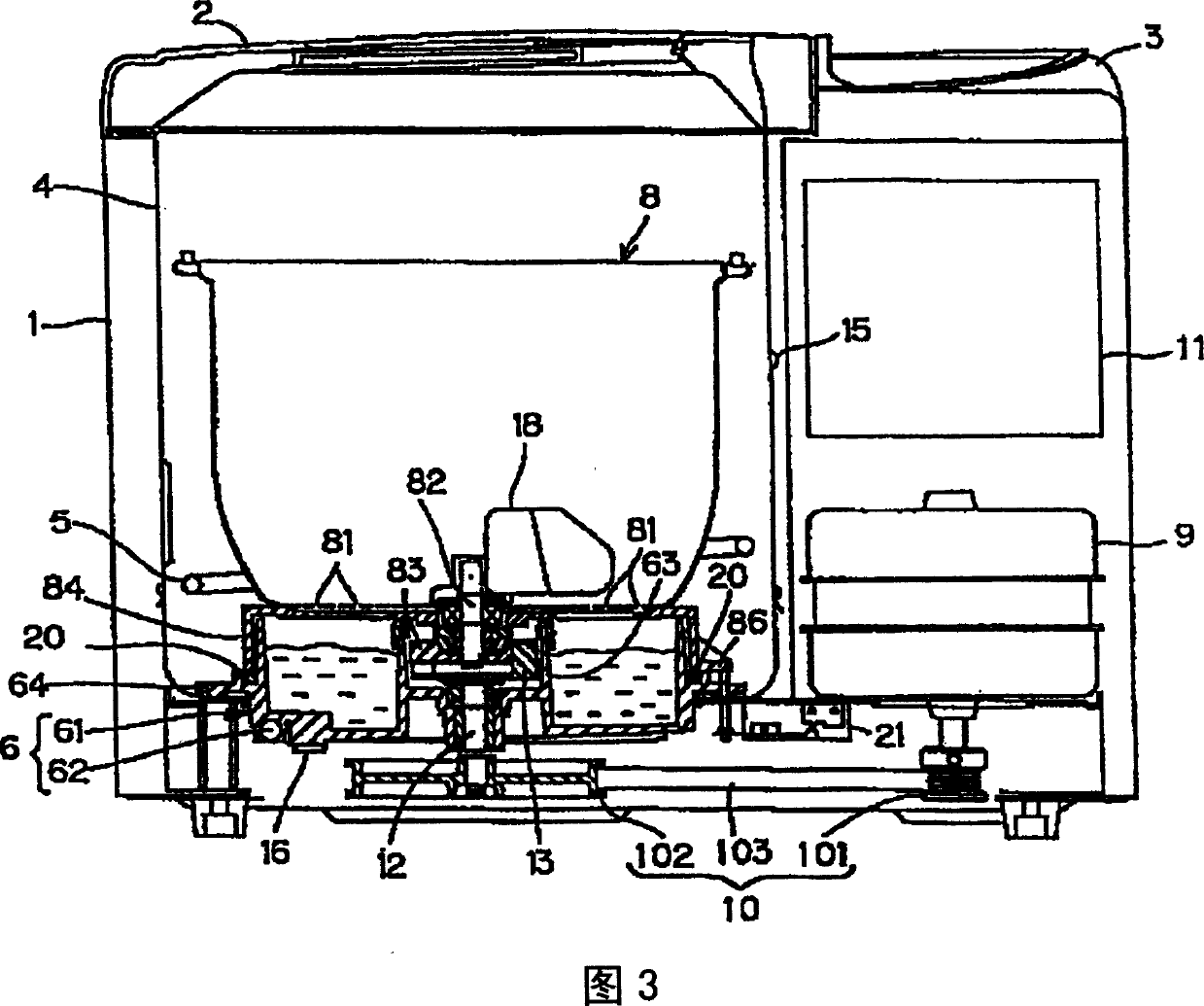

[0045] The automatic bread maker 99 will be described in more detail below in conjunction with FIGS. 2-8 . In addition, Fig. 2 is a longitudinal sectional view of an automatic bread maker 99 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com