Component for light isolator, its mfg. method and light isolator using such component for light isolator

A technology of optical isolator and manufacturing method, applied in optical components, optics, instruments, etc., can solve the problems of deterioration of optical characteristics, increase of thermal stress, deterioration of extinction ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

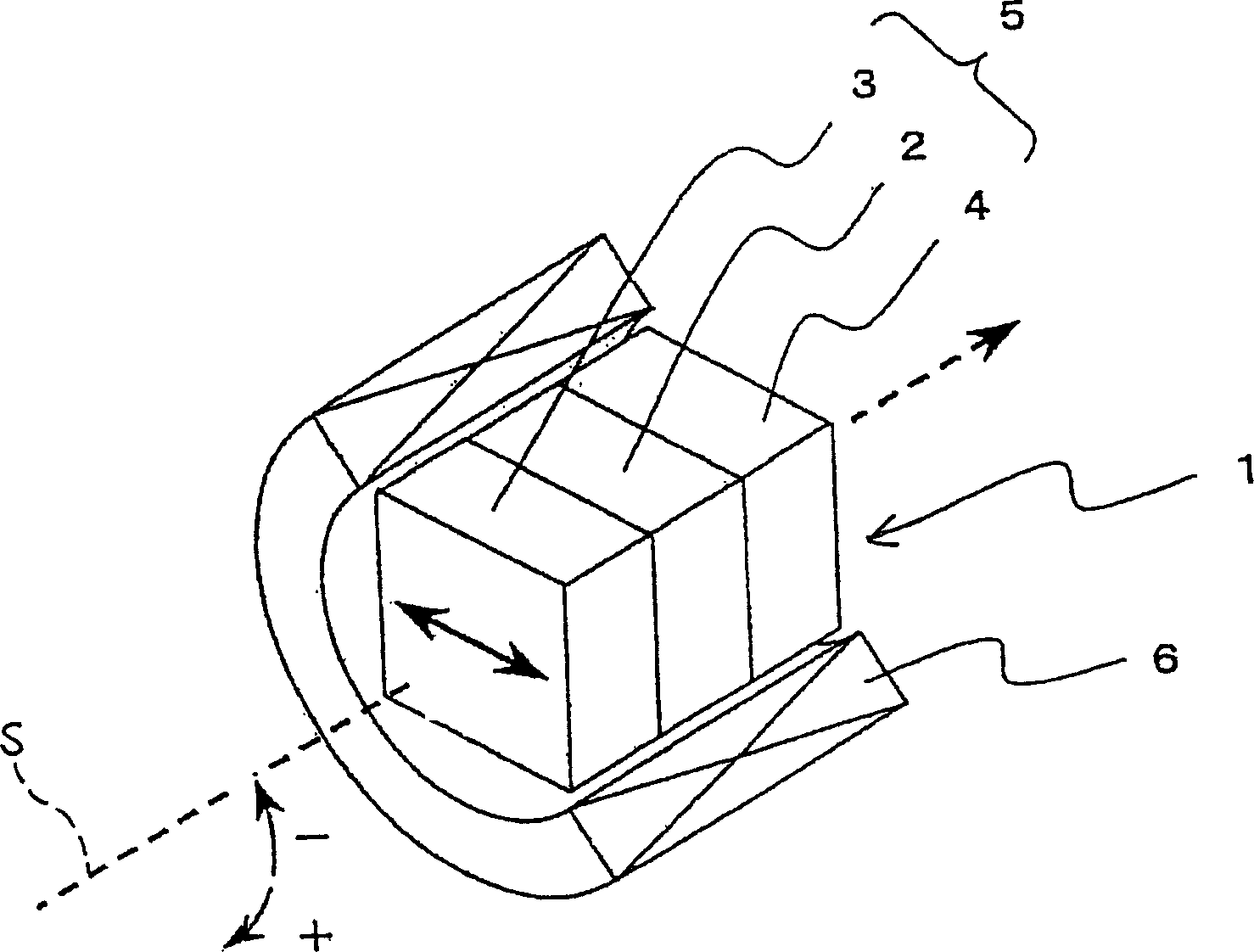

[0044] figure 1 It is a perspective view showing a main part of an optical isolator related to an embodiment of the present invention by cutting away. In this figure, an optical isolator 1 includes an optical isolator element 5 that is integrated by laminating flat polarizers 3 and 4 on both sides of a flat Faraday Rotator (Faraday Rotator) 2. And the cylindrical magnet body 6 which accommodates the element 5 for optical isolators. In addition, as will be described later, the optical isolator element 5 is manufactured by bonding a similarly large polarizer substrate to both sides of a large Faraday rotator substrate, and then subdividing it into appropriate sizes.

[0045] The Faraday rotator 2 is made of, for example, a bismuth-substituted garnet crystal or the like, and its thickness is set so that the polarization plane of incident light having a predetermined wavelength is rotated by 45 degrees. In general, in order to rotate the plane of polarization, it is necessary t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com