Nail polish composition comprising a gradient polymer and the cosmetic process of treating or caring for nails

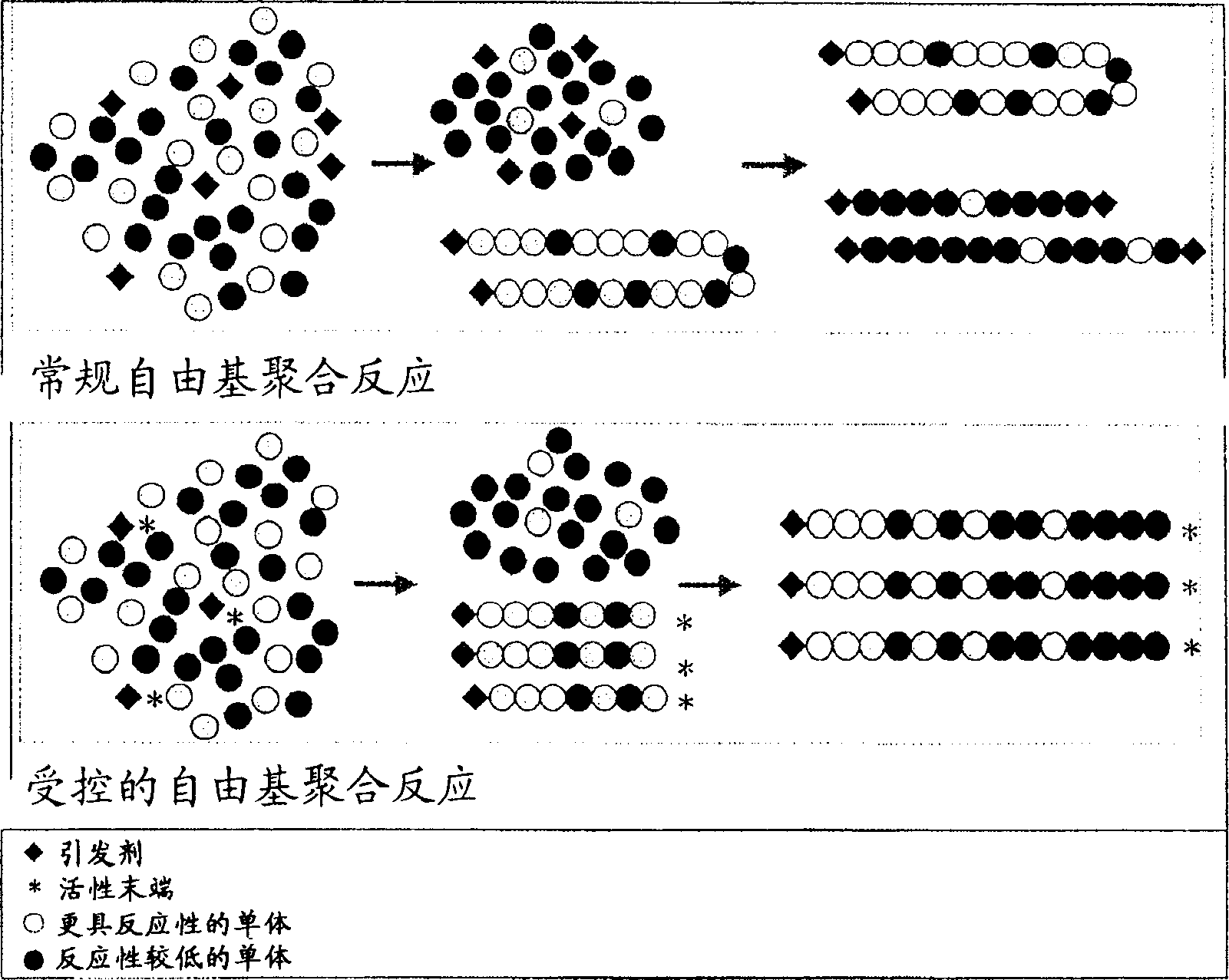

A gradient copolymer and composition technology, which can be used in medical preparations containing active ingredients, cosmetics, manicure, etc., and can solve problems such as polymer phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0250] Embodiment 1: the bulk synthesis of gradient copolymer

[0251] The mixture of reactants is as follows:

[0252] -MONAMS: 3.0g

[0253] -SG1: 0.18g

[0254] - Ethyl acrylate: 480g i.e. 80% by weight / total weight of monomers

[0255] - Styrene: 60g i.e. 10% by weight / total weight of monomers

[0256] -Methacrylic acid: 60g i.e. 10% by weight / total weight of monomers

[0257]The combined components were mixed under a nitrogen atmosphere in the absence of solvent, then heated for 198 minutes at a temperature maintained between 110 and 115°C. The reaction was stopped at 60% conversion.

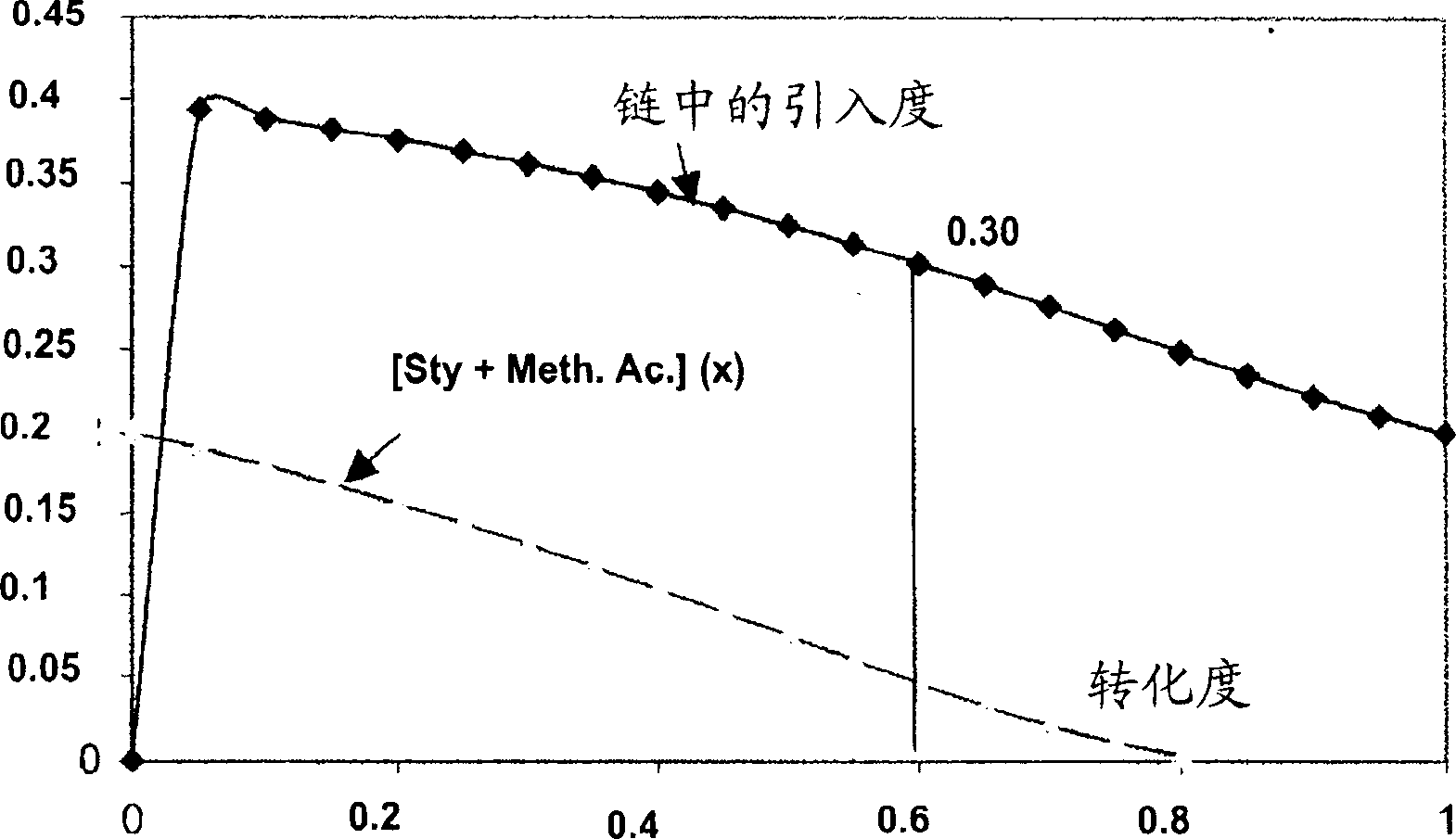

[0258] The simulated calculation of the gradient gives figure 2 the curve shown. Theoretical predictions lead to an incorporation of 30% (styrene / methacrylic acid) mixture and 70% ethyl acrylate.

[0259] Monitoring of the relative concentrations of the three monomers by gas chromatographic and NMR analysis of the polymer confirmed this model. By these methods, the final chemica...

Embodiment 2

[0269] Example 2: Bulk synthesis of gradient copolymers

[0270] Various copolymers were prepared according to the procedure described in Example 1, starting from the reactant mixture as follows:

[0271] -MONAMS: 3.0g

[0272] -SG1: 0.18g

[0273] - Styrene: 60g

[0274] -Methacrylic acid: 60g

[0275] Example

Embodiment 3

[0276] Example 3: Synthesis carried out in the presence of a solvent

[0277] The same synthesis as in Example 1 was carried out except in the presence of a solvent.

[0278] The mixture of reactants is as follows:

[0279] -MONAMS: 3.43g

[0280] -SG1: 0.2g

[0281] - Ethyl acrylate: 336g

[0282] - Styrene: 42g

[0283] -Methacrylic acid: 42g

[0284] -Toluene: 180g

[0285] The combined components were mixed in toluene as solvent under nitrogen atmosphere and then heated for 198 minutes at a temperature maintained between 110 and 115°C.

[0286] The final conversion was 82% and the resulting solids level was 57.2% by weight.

[0287] The following analysis results were obtained:

[0288] Mn=30 570 g / mol, Mw=50 500 g / mol and PI=1.65. The degree of dispersion (or w) of the composition was 2.0.

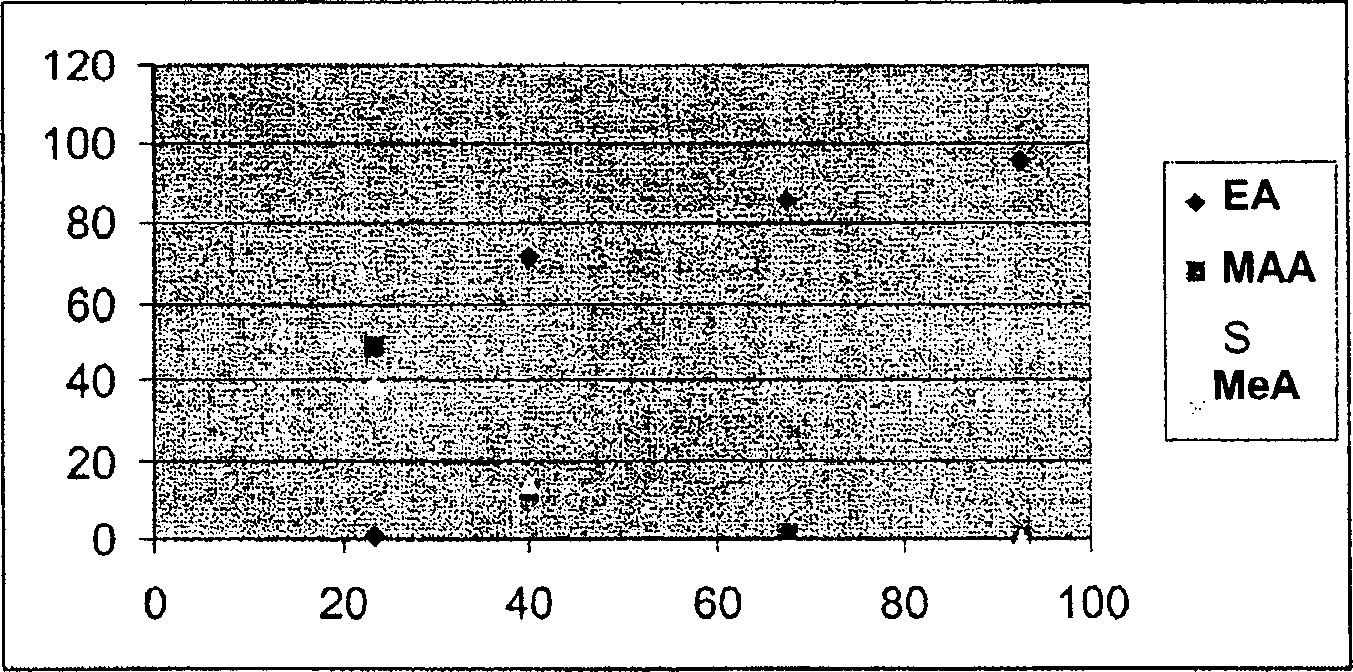

[0289] The final composition of the copolymer was given by liquid adsorption chromatography (LAC), which showed a similar composition to the copolymer prepared in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com