Device for treating powder particles by rotary flow

A processing device, powder and granular technology, applied in the direction of mixer with rotating stirring device, powder suspension method granulation, raw material granulation method, etc., can solve the problem of fine powder and granular flying, uncontrollable formation good etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail based on a flow processing device for powder and granular bodies in a preferred embodiment.

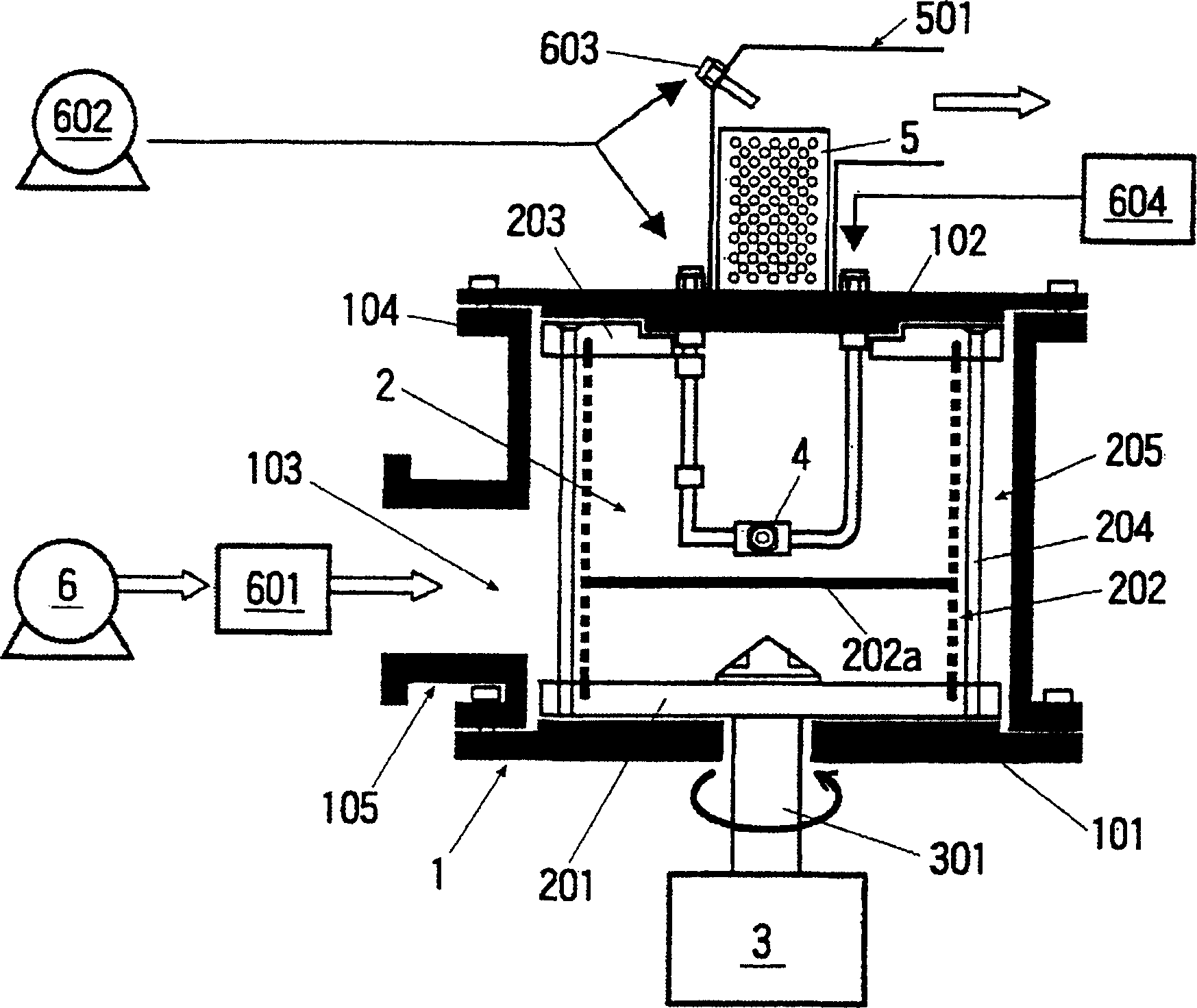

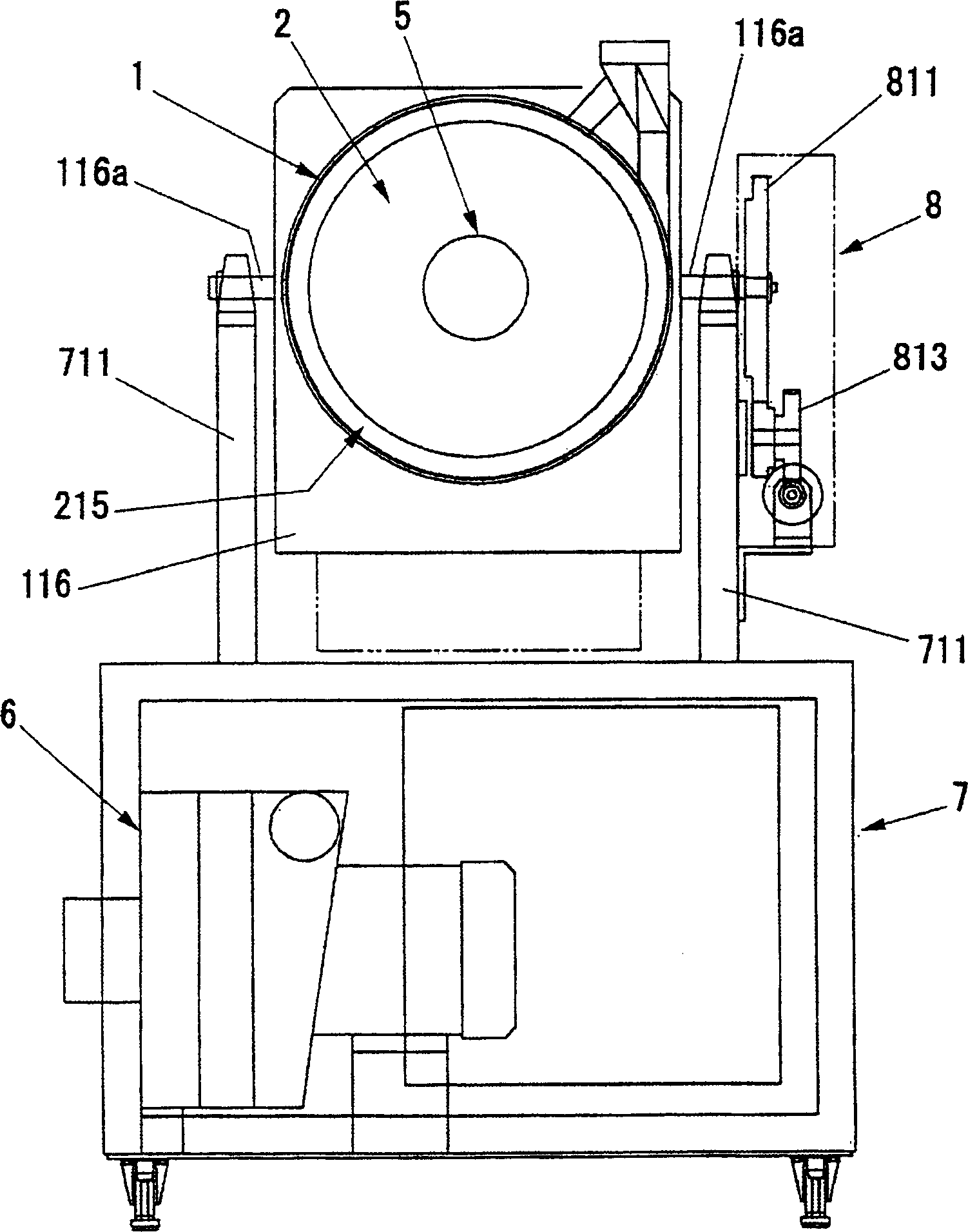

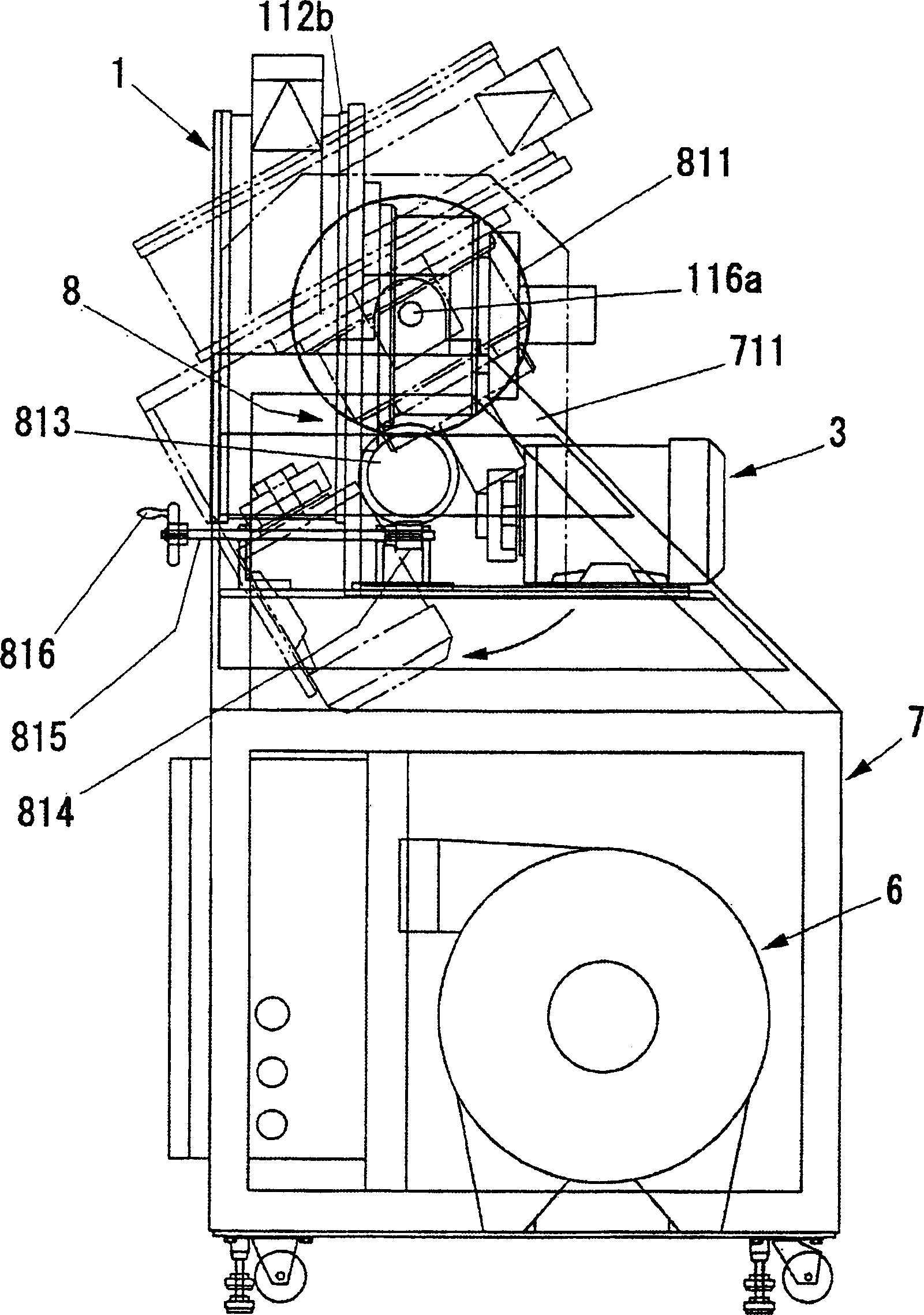

[0035] refer to figure 1 and the same as the second embodiment Figure 11 A first embodiment in which the device is configured vertically will be described. Reference numeral 1 is a cylindrical casing, and a cylindrical processing chamber 2 for processing powdery or granular materials is arranged in the casing 1 with a certain space apart from the inner wall surface of the casing 1 .

[0036] In the processing chamber 2 , the lower fixing plate 201 is rotatably and interlockingly connected to the driving device 3 via the rotating shaft 301 . The peripheral panel 202 provided on the outer peripheral surface of the processing chamber 2 constitutes a predetermined ventilation device for allowing predetermined gases such as various gases and air to flow into the processing chamber 2, and forms a structure that can ventilate from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com