Gold, silver and glass, ceramic layered composite container and making method thereof

A technology of ceramic containers and composite containers, which is applied in the direction of ceramic containers, coverings/external coatings, etc., can solve the problems of limited application prospects, unsuitable process modeling, and cannot be effectively avoided, so as to achieve broad application prospects and enrich product types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

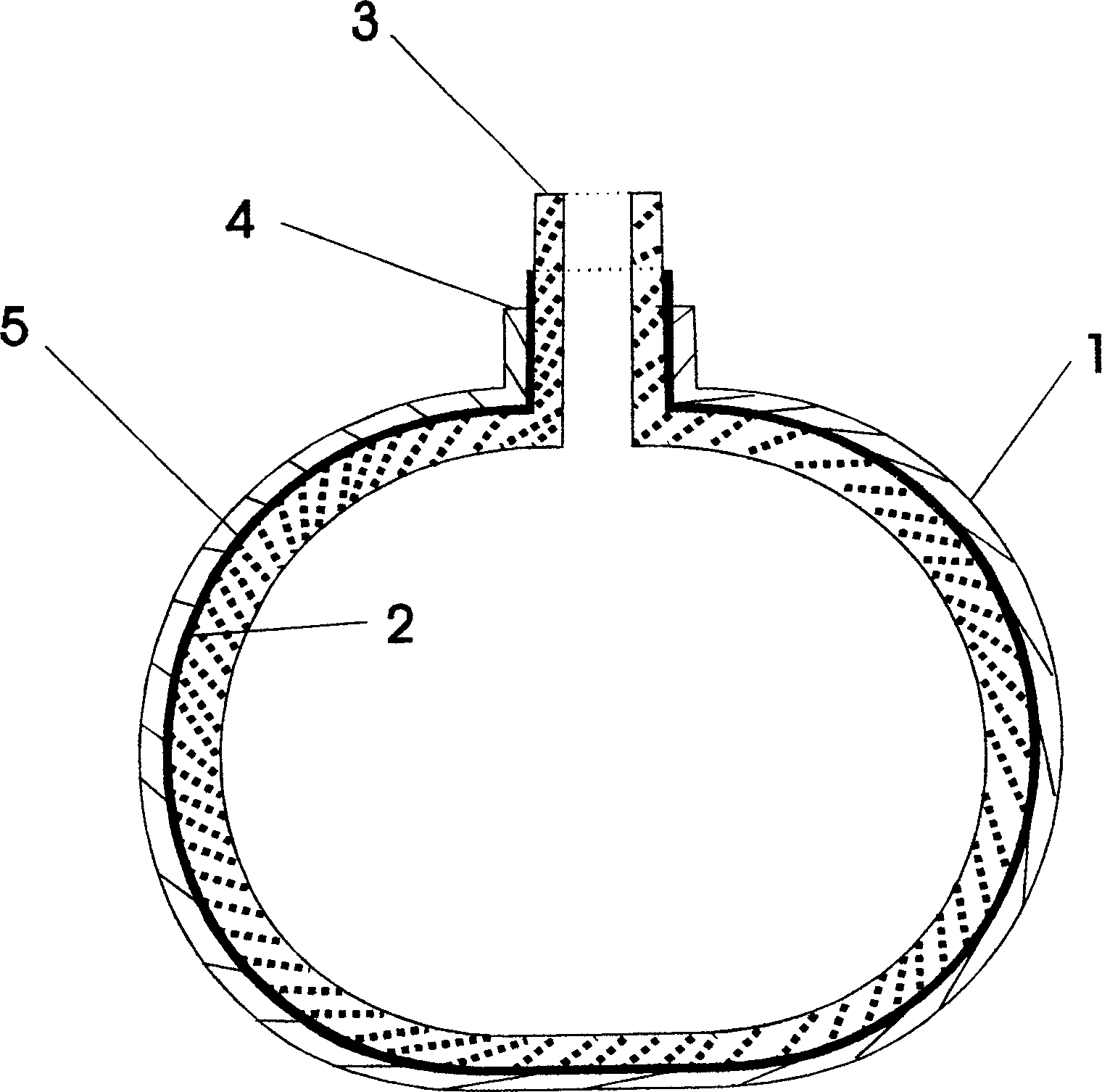

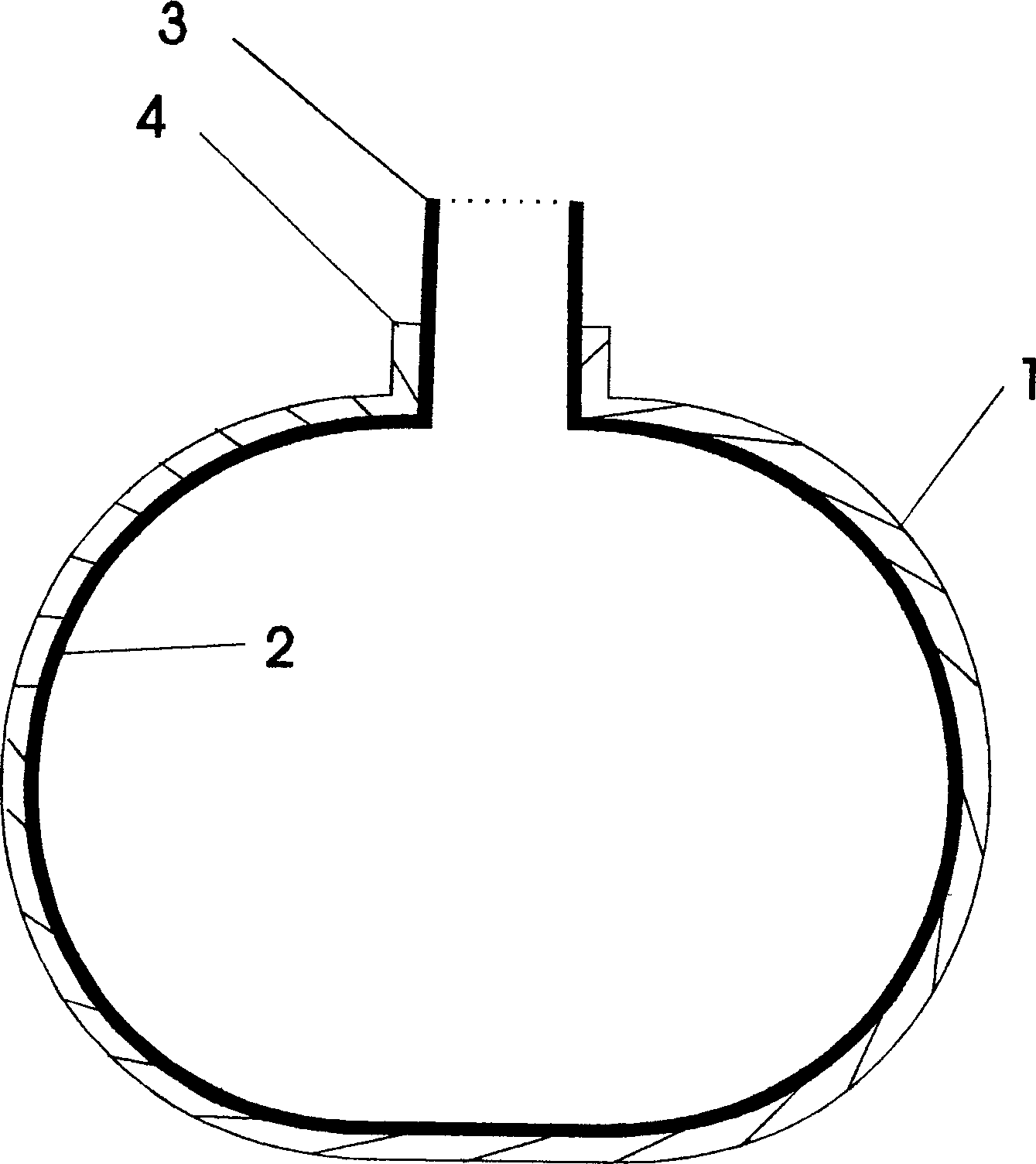

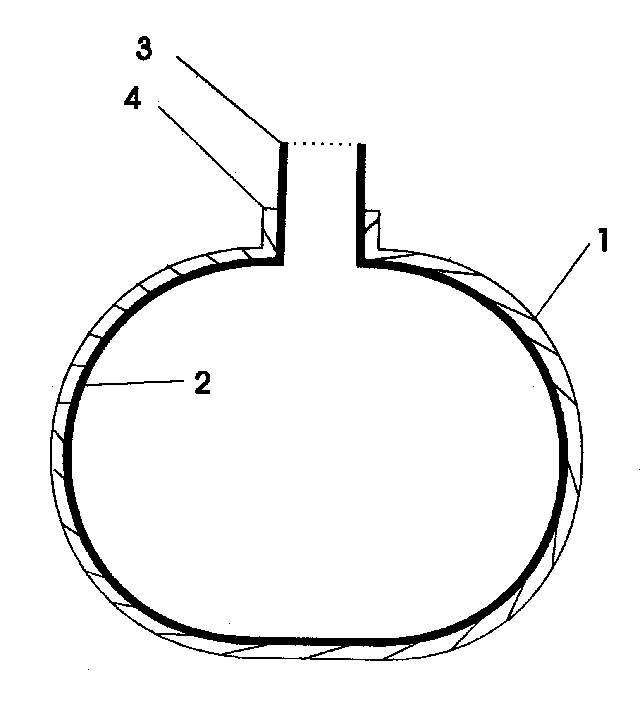

[0012] Such as figure 1 , figure 2 As shown, the gold and silver coat or ring-shaped gold and silver coat 1 of the present invention is made of gold and silver, and the surface of the gold and silver coat is decorated with decorative patterns or accessories of any shape. , handle, the gold and silver coats have openings 4 (the ring-shaped gold and silver coats are two opposite openings), and the inner chambers of the above-mentioned gold and silver coats 1 are built with glass and ceramic containers 2 with openings 3 (see figure 1 , figure 2 ).

[0013] When making gold, silver and glass of the present invention, ceramic layered composite container, embodiment one is: as figure 1 As shown, first make the inner layer glass and ceramic container (2) that can accurately match the gold and silver coat (1) wax pattern (5) with glass and ceramic molds, and then install the above-mentioned inner layer container (2) in the manufacturing In the inner cavity of the wax mold (5) re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com