Optical module and manufacturing method of the same, optical communication device, photoelectric hybrid integrated circuit, circuit board, electronic device

A technology of optical modules and paths, applied in the coupling of optical waveguides, installation of optical fibers/cables, optics, etc., can solve problems such as damage to the light-emitting surface and attachment of foreign objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

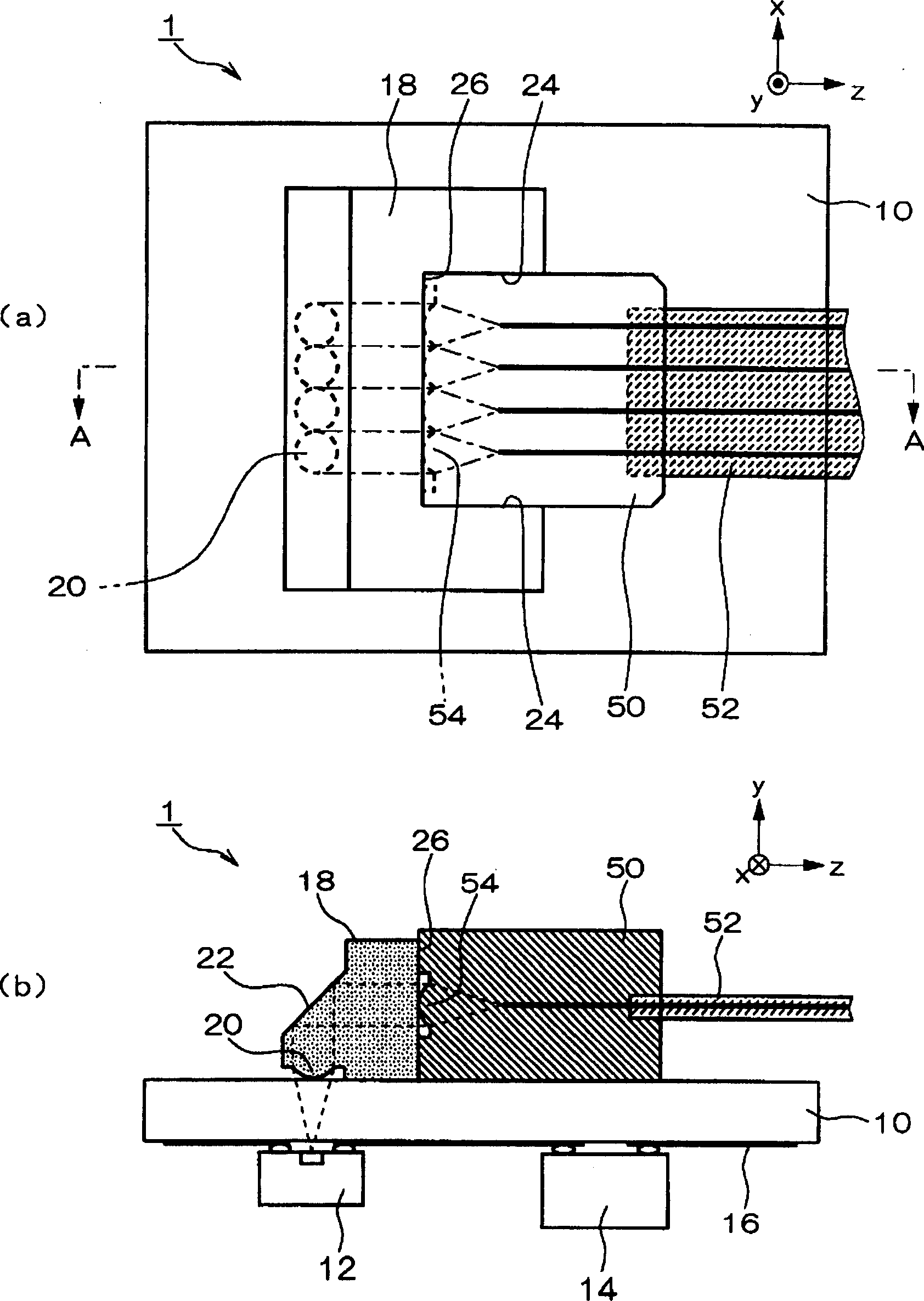

[0069] Figure 5 is a schematic diagram of the configuration of the optical module of the second embodiment. Figure 5 (a) is a plan view of the optical module of the present embodiment, Figure 5 (b) is along Figure 5 A cross-sectional view taken along line B-B in (a). The optical module 1a shown in this figure has basically the same configuration as the optical module 1 of the first embodiment, and common constituent elements are denoted by the same reference numerals. Hereinafter, differences will be mainly described.

[0070] Such as Figure 5 The optical module 1a shown differs from the first embodiment in the shape of the optical receptacle 18a to which the optical plug 50 is mounted. The optical receptacle 18a of this embodiment includes the surface 24 and the surface 26 as the guide surfaces similarly to the optical receptacle 18 described above, and also includes the surface 32 for determining the position of the optical module 1a in the y-axis direction. This ...

no. 3 Embodiment

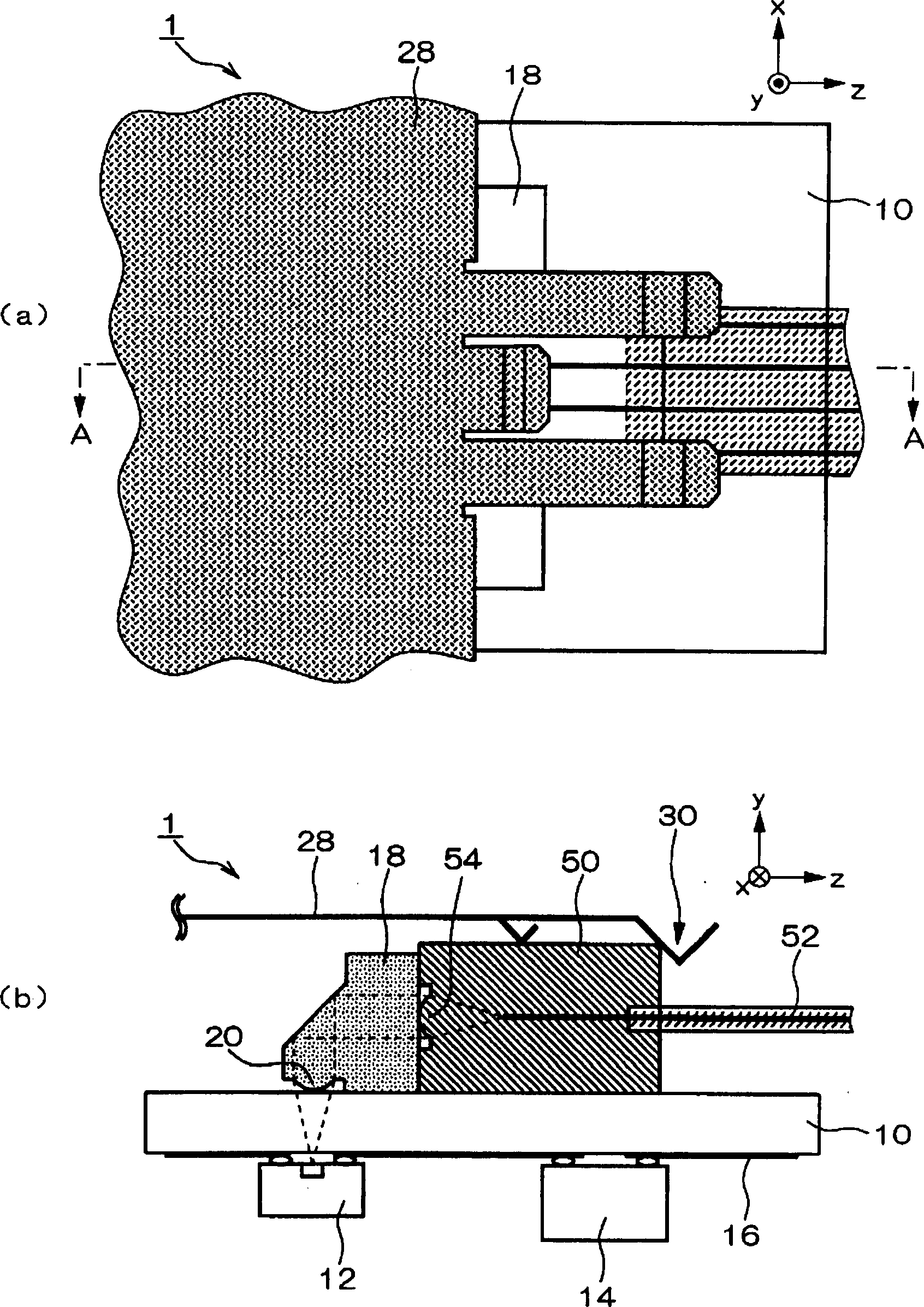

[0073] Figure 6 is a schematic diagram of the configuration of the optical module of the third embodiment. Figure 6 (a) is a plan view of the optical module of the present embodiment, Figure 6 (b) is along Figure 6 A cross-sectional view taken along line C-C in (a). The optical module 1b shown in this figure has basically the same configuration as the optical modules of the above-mentioned embodiments, and the common constituent elements are denoted by the same symbols. Hereinafter, differences will be mainly described.

[0074] Such as Figure 6 In the shown optical module 1b, the shape of the optical receptacle 18b for mounting the optical plug 50 is different from that of the above-mentioned embodiments. The optical receptacle 18b of this embodiment includes the surface 24a, the surface 26a, and the surface 32a as guide surfaces similarly to the above-mentioned optical receptacle 18a. The functions of the surface 24a, the surface 26a, and the surface 32a are the s...

no. 4 Embodiment

[0077] Figure 7 is a schematic diagram of the configuration of the optical module of the fourth embodiment. Figure 7 (a) is a plan view of the optical module of the present embodiment, Figure 7 (b) is along Figure 7 A cross-sectional view taken along line D-D in (a). The optical module 1c shown in this figure has the same configuration as the optical module of each of the above-mentioned embodiments, and common constituent elements are denoted by the same reference numerals. Hereinafter, differences will be mainly described.

[0078] Such as Figure 7 The illustrated optical module 1c has a configuration in which an optical plug 50b and an optical receptacle 18c can be directly mounted. Specifically, the optical receptacle 18c includes a surface 26b as a guide surface, and the optical connector 50b is mounted by adhering the surface 26b and the bonding surface provided on the optical connector 50b.

[0079] Furthermore, in this example, the lens 54b as the second len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com