Coal injection device for blast furnace ironmaking

A blast furnace ironmaking and spray gun technology, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve problems such as the inapplicability of coal injection equipment, and achieve the effect of ensuring the cooling strength of the furnace lining, ensuring the life of the blast furnace, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

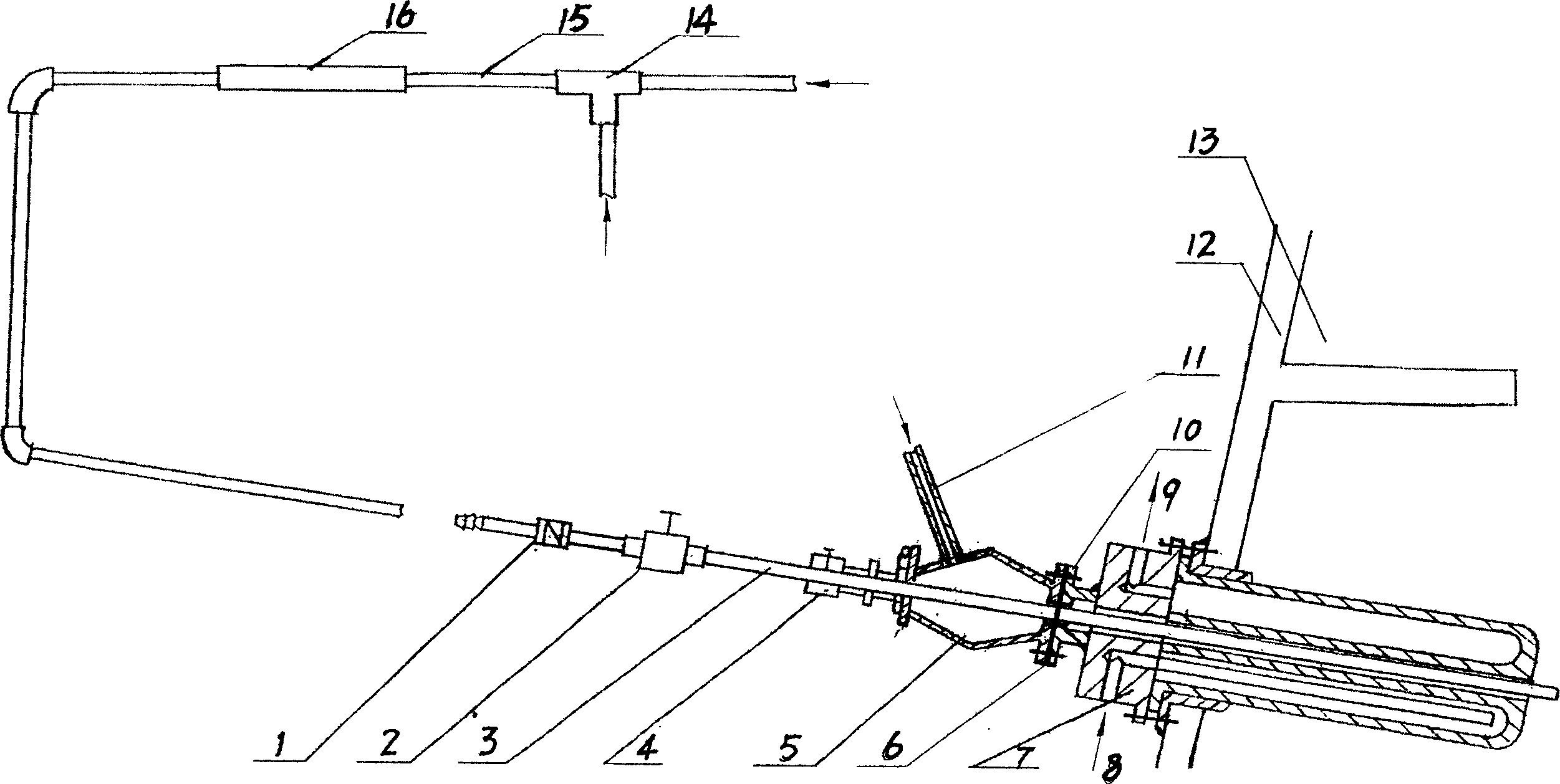

[0008] With reference to the accompanying drawings, a blast furnace ironmaking coal injection device suitable for blast furnace ironmaking two-stage pulverized coal injection process method consists of a coal delivery pipeline 15, a date-shaped ball valve 5, a spray gun 3, a check valve 1, a ball valve 2, Compression sleeve 4, high-pressure gas inlet pipe 11 and other components, jujube-shaped ball valve 5 connected to high-pressure gas inlet pipe 11, the center of the spray gun cooling water jacket 7 has a through hole, the side wall is provided with a cooling water cavity, and the head is provided with cooling water The water inlet 8, the cooling water outlet 9, the cooling water cavity communicates with the cooling water inlet 8, the cooling water outlet 9, the head of the spray gun cooling water jacket 7 is fixed on the blast furnace shell 12, and the tail extends into the blast furnace cavity 13 The jujube-shaped ball valve 5 and the spray gun cooling jacket 7 are sealed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com