Magnetron cathode and magnetron sputtering apparatus comprising the same

A magnetron cathode and magnetron sputtering technology, which is applied to the cathode of transit time electron tubes, sputter coating, discharge tubes, etc., can solve the problems of high corrosion degree, unbalanced corrosion profile, target corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

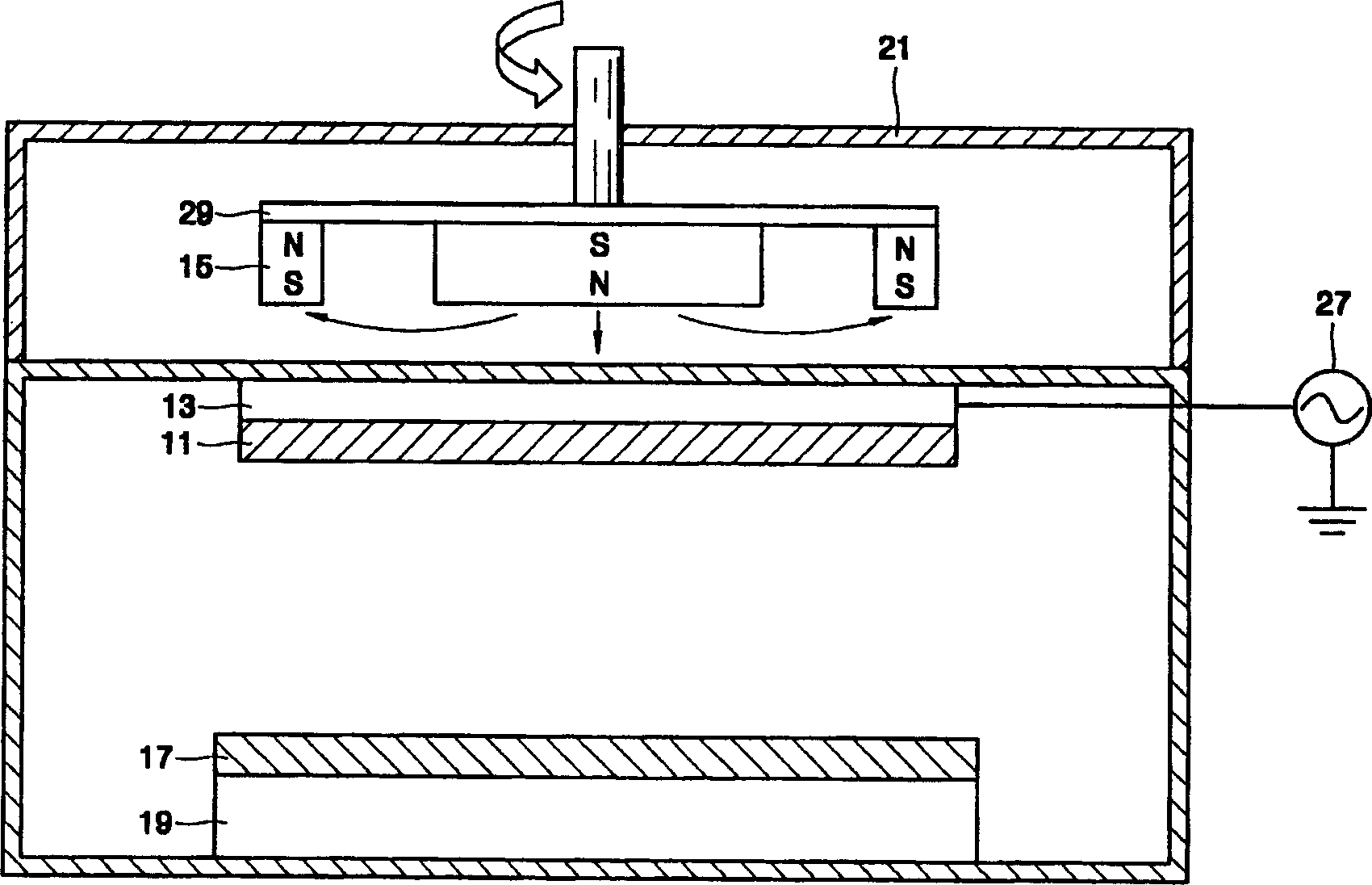

[0047] Hereinafter, a magnetron cathode and a magnetron sputtering apparatus including the magnetron cathode according to the present invention will be described in detail with reference to the accompanying drawings.

[0048] Fig. 5 is a schematic cross-sectional view of a magnetron cathode according to the present invention.

[0049]Referring to FIG. 5, a magnetron cathode according to the present invention includes three or more magnet units, each magnet unit includes a single or a plurality of magnets, and the same magnetic pole of these magnets faces the target. Opposite poles of adjacent magnet units face the target. One magnet unit is arranged around the periphery of the other magnet unit. For example, as shown in Figure 5, the first magnet unit 35a is arranged in the innermost region with the S pole facing the target, and the second magnet unit 35b is arranged around the periphery of the first magnet unit 35a with the N pole facing the target, so that The third magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com