Microstructure mold core making technology

A microstructure and microstructure technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as inability to process microstructures, achieve high yield, overcome dimensional accuracy, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

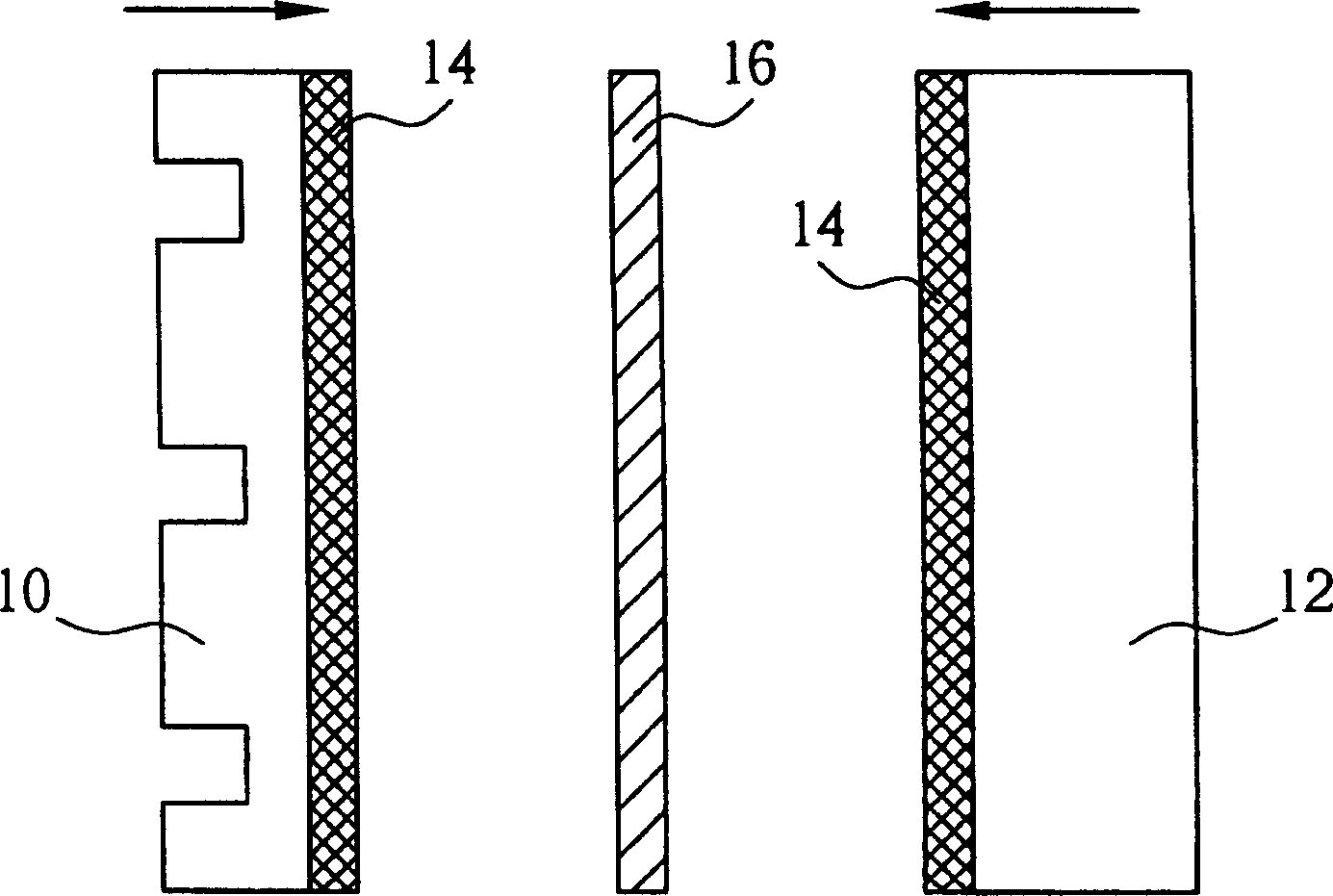

[0014] see figure 1 , figure 1 It is a schematic cross-sectional view of the metal bonding technology of the present invention. In the process of mold core production, the most important thing is to consider the impact of future product molding and the subsequent effect, so as not to affect the quality of the microstructure of the finished product. Therefore, it must be pressurized to maintain the flatness of the surface of the mold core. However, the general pressure method is easy to damage the surface microstructure of the metal sheet. like figure 1 As shown, the metal bonding technique used in the present invention is to first electroplate the copper metal layer 14 on the surface of the metal thin plate 10, such as a nickel plate, and the mold core 12, and then fill the two copper metal layers 14 with indium (In) or The intermediate bonding layer 16 of the indium alloy is heated to 200 to 400° C. and pressurized to 300 to 400 kg / cm 2 The two metal layers 14 are adhere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com