Polymer-coated heat-sealable packaging material, method for manufacturing the same and a closed package made thereof

A packaging material and sealing packaging technology, applied in the fields of polymer-coated packaging materials, polymer heat-sealing layers, and packaging parts, can solve problems such as insufficient water vapor barrier, and achieve the effect of strengthening protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

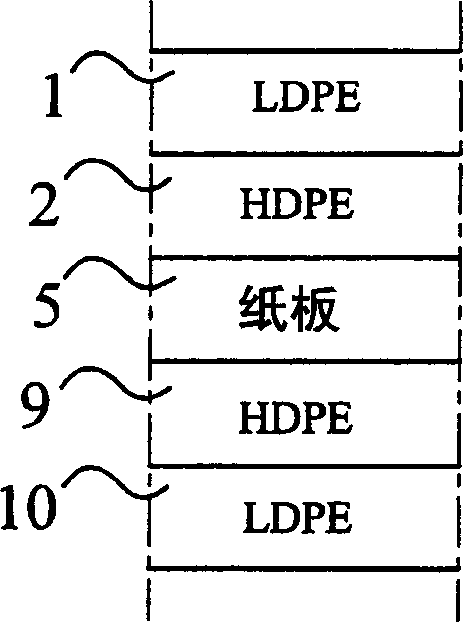

[0037] Preparation of an extrusion coated packaging board with layer structure: LDPE layer, weight 5g / m 2 , HDPE layer, weight 15g / m 2 , bottom plate, weight 190g / m 2 , HDPE layer, weight 15g / m 2 And LDPE layer, weight 5g / m 2 . At a temperature of 38° and a relative humidity of 90%, the water vapor permeability of the paperboard was measured to be 6.4g / m 2 / d. The cardboard had significantly less curl.

Embodiment 2

[0039] Prepare an extrusion coated packaging board with layer structure: LDPE layer, weight 10g / m 2 , HDPE layer, weight 10g / m 2 , bottom plate, weight 255g / m 2 , HDPE layer, weight 20g / m 2 And LDPE layer, weight 25g / m 2 . At a temperature of 38° and a relative humidity of 90%, the water vapor permeability of the paperboard was measured to be 4.6g / m 2 / d. The result is the average of the permeability values measured in different directions.

Embodiment 3

[0040] Embodiment 3 (reference)

[0041] For reference, an extrusion coated paperboard was prepared with the layer structure: LDPE layer, weight 20g / m 2 , bottom plate, weight 255g / m 2 , HDPE layer, weight 20g / m 2 And LDPE layer, weight 20g / m 2 . The paperboard has an average water vapor permeability of 5.5g / m 2 / d. The paperboard was significantly more curled than the paperboard described in Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com