Method for working nut screw of ball screw

A ball screw and processing method technology, applied in metal processing, metal processing equipment, applications, etc., can solve the problems of increased nut processing costs and increased processing time, and achieve the effects of shortening processing time and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

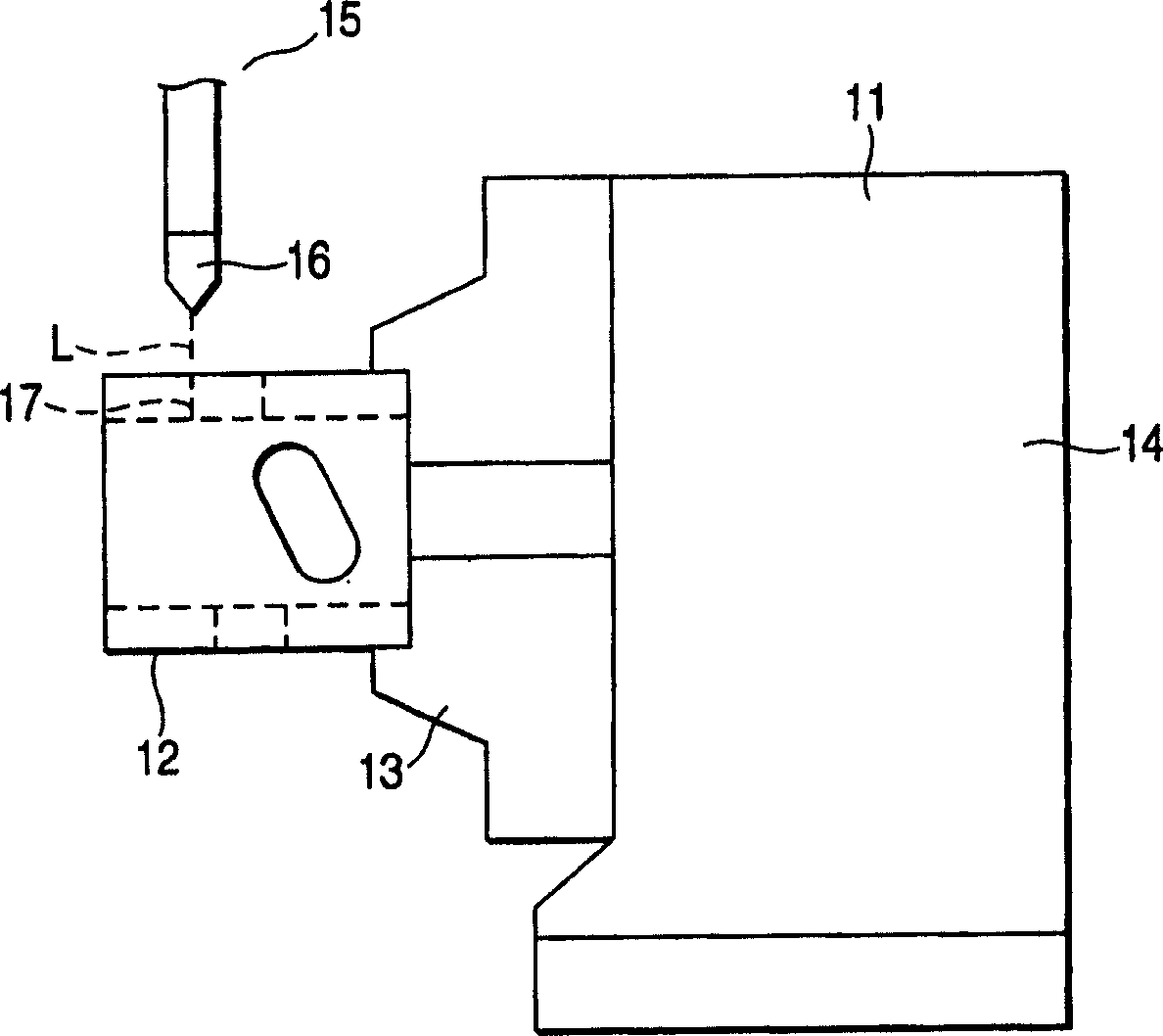

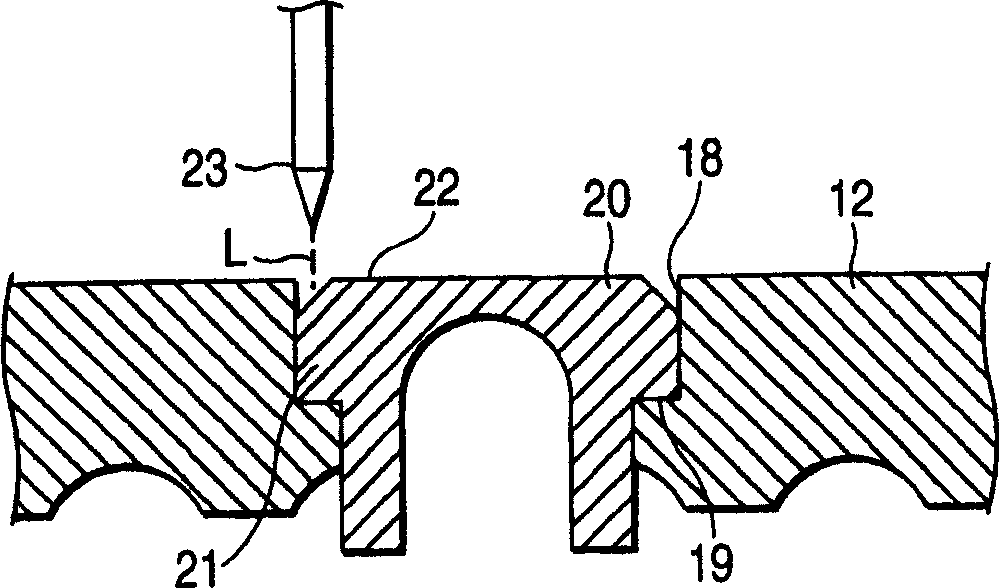

[0029] Now, with reference to the accompanying drawings, the preferred processing methods for nuts for ball screws are given below

[0030] Description of Examples.

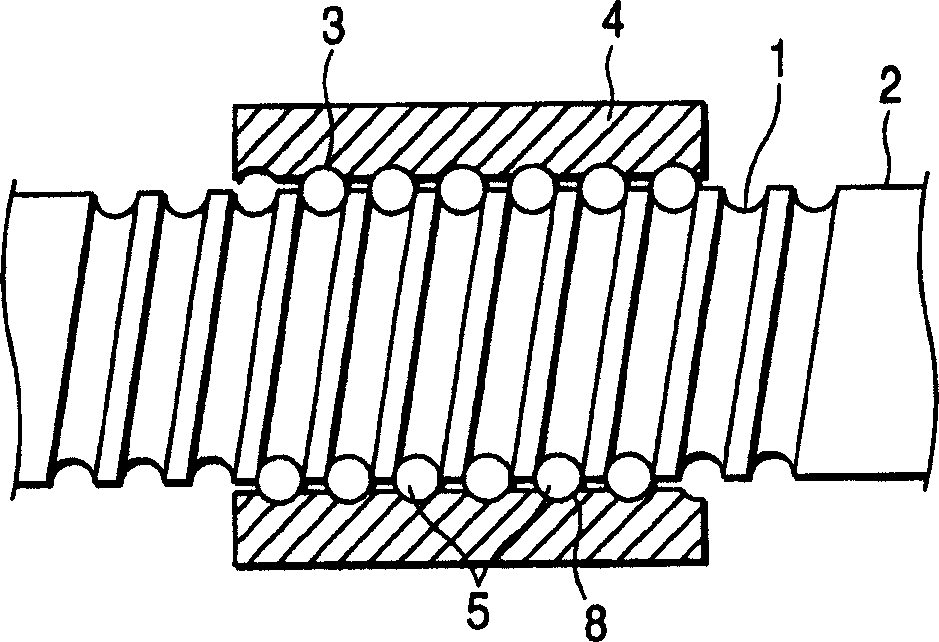

[0031] figure 1 is a longitudinal sectional side view of the ball screw according to the first embodiment of the present invention. The ball screw includes a screw shaft 2 and a nut 4, wherein the screw shaft 2 includes a helical groove 1, and the nut 4 includes a helical groove 3, and makes a plurality of balls 5 in the helical groove of the screw shaft 2 and the nut 4 Scroll between 1 and 3. Generally, the spiral groove 1 of the screw shaft 2 is formed by rolling working using a rolling die, or is formed by grinding so as to have a Gothic arch shape. On the other hand, the helical groove 3 of the nut 4 is machined with a lathe, or cut with a specially designed rotary tool, so as to have a gothic arched shape.

[0032]Subsequently, the blank of the nut 4 is heat-treated, for example by carburizing and quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com