Chlorineless bleaching paper pulp producing process using pith removed corn stalk as raw material

A chlorine-free bleaching and pulping technology, applied in the field of papermaking, can solve the problems of lack of materials and unfavorable people's survival, and achieve the effect of reliable resources and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

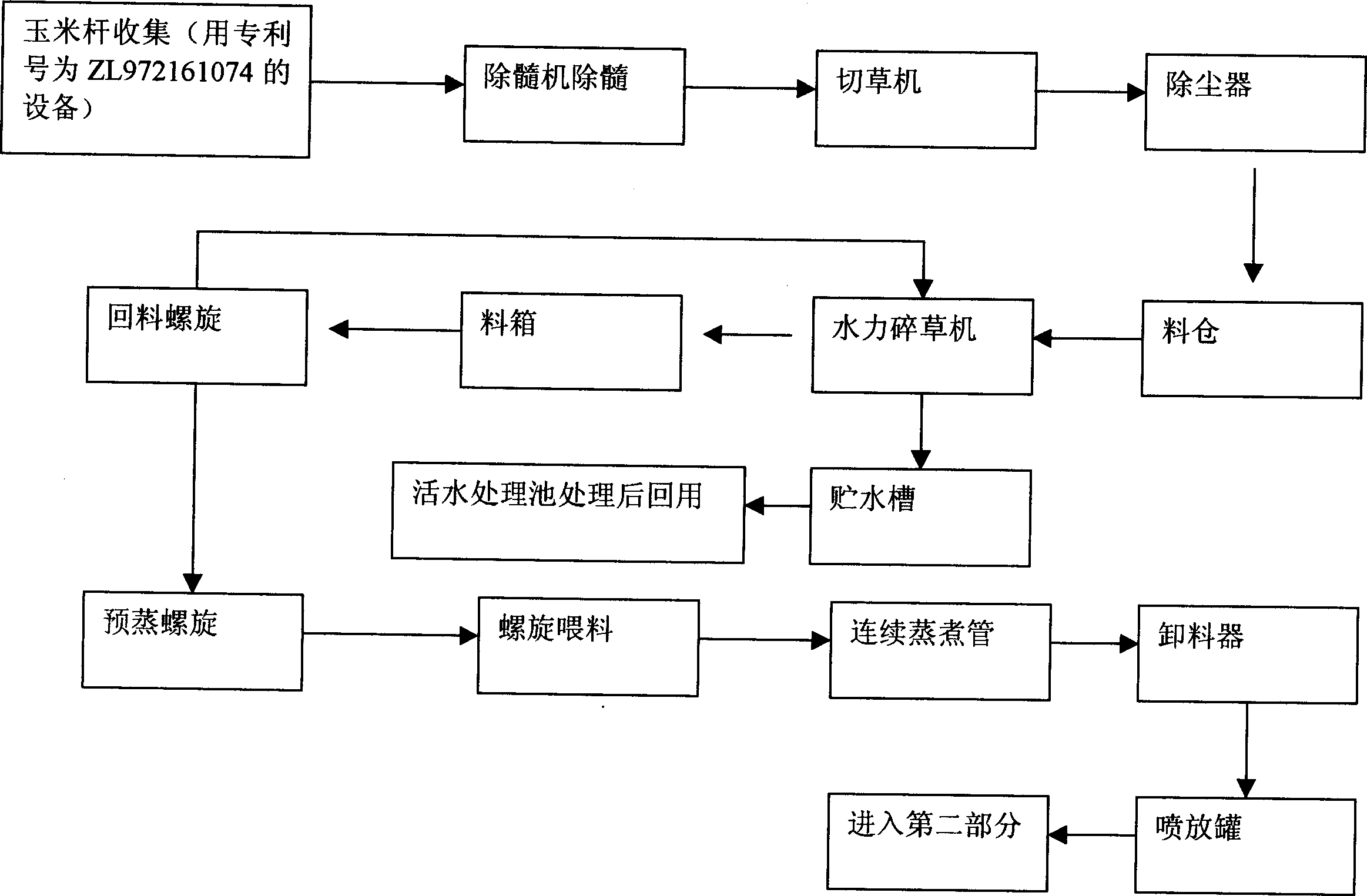

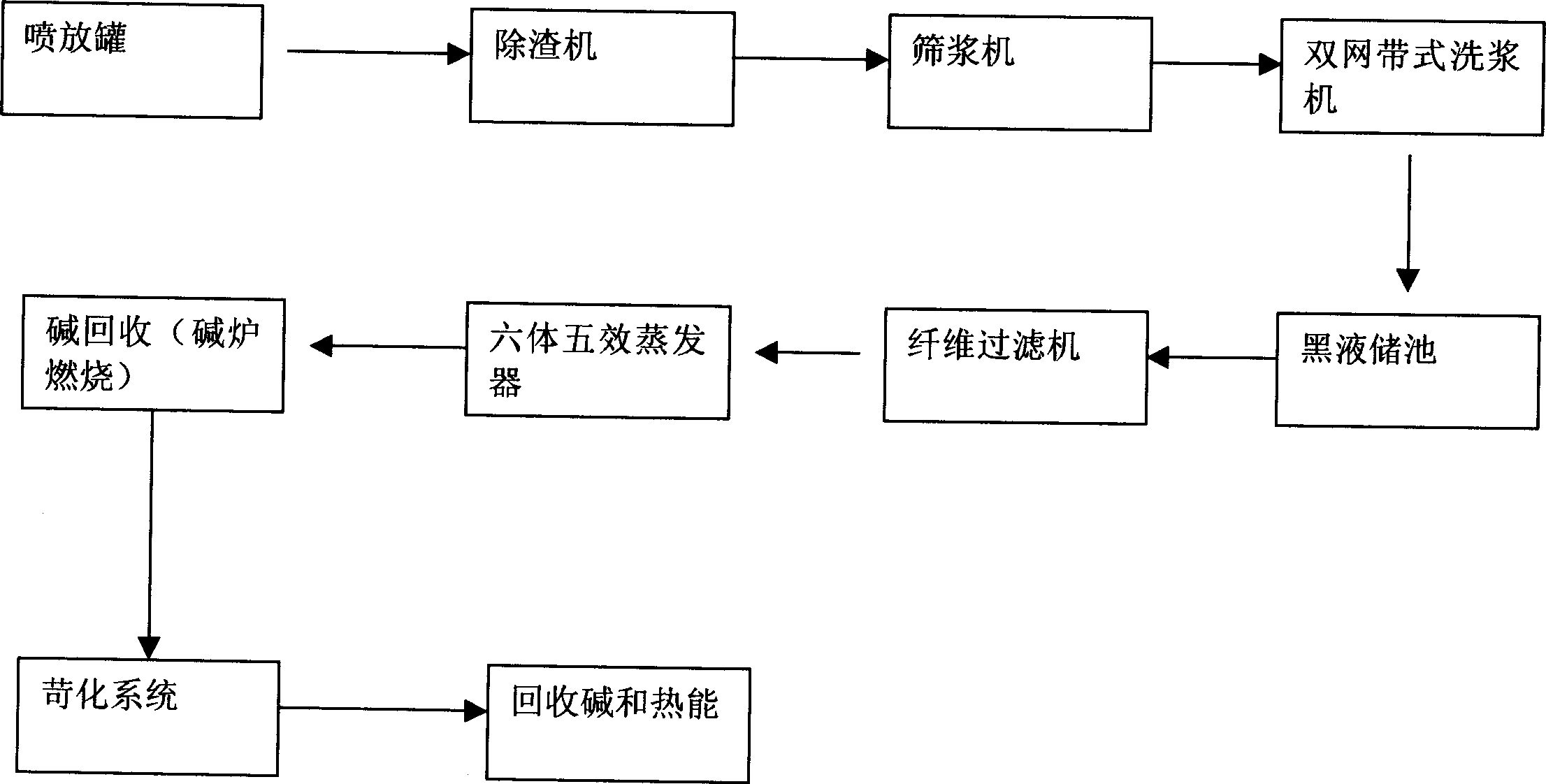

[0024] Step 1: Ingredients and Cooking

[0025] Use whole corn stalks (without pith removal) to make paper, cut (shred) the stalks, and then use water power to remove the pith, so not only does it consume more water, but the most important thing is that the pith removal is not clean, and the corn pith enters the cooking system, which requires more consumption NaOH. Because the pith contains too much sugar and pectin, the quality of the cooked pulp is not high, which causes great trouble to the subsequent process, consumes a lot of chemicals, the yield is low, the pulp is not well filtered, the yield is low, and the quality is poor. Influence the development of cornstalk as a raw material for papermaking. The demyelination technology that the present invention adopts just overcomes this disadvantage.

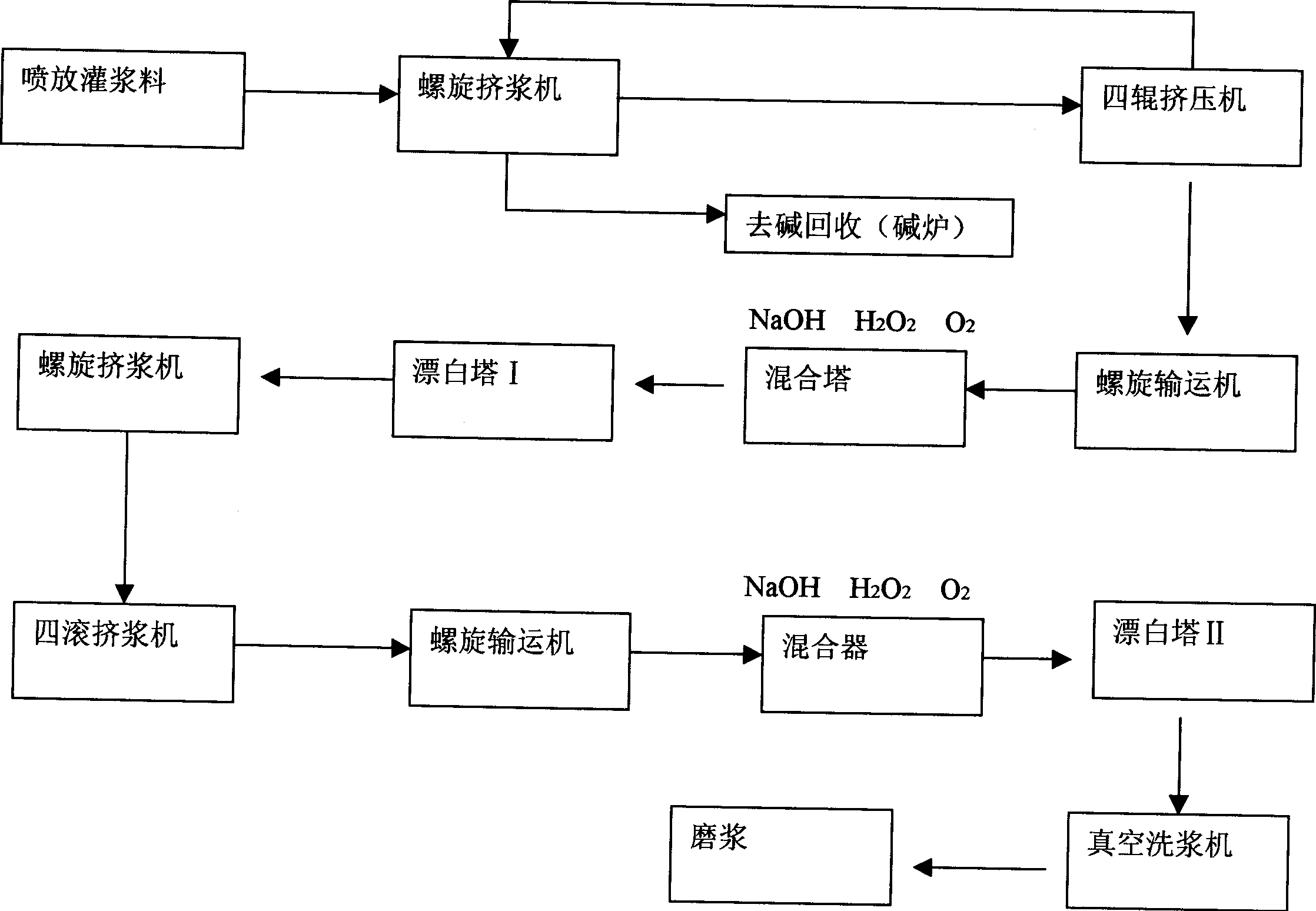

[0026] The second step: pulping TCF (Totally chlorine Free) bleaching process

[0027] There are two technical points in this process: one is to squeeze the pulp thoroughly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com