Environment-friendly type dreg-free calcium hydrophosphate production formula and method

An environmentally friendly technology of calcium hydrogen phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of land occupation, difficulty in maintaining manufacturers, and impact on the environment, and achieve high yield, reliable resources, and white fertilizers. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

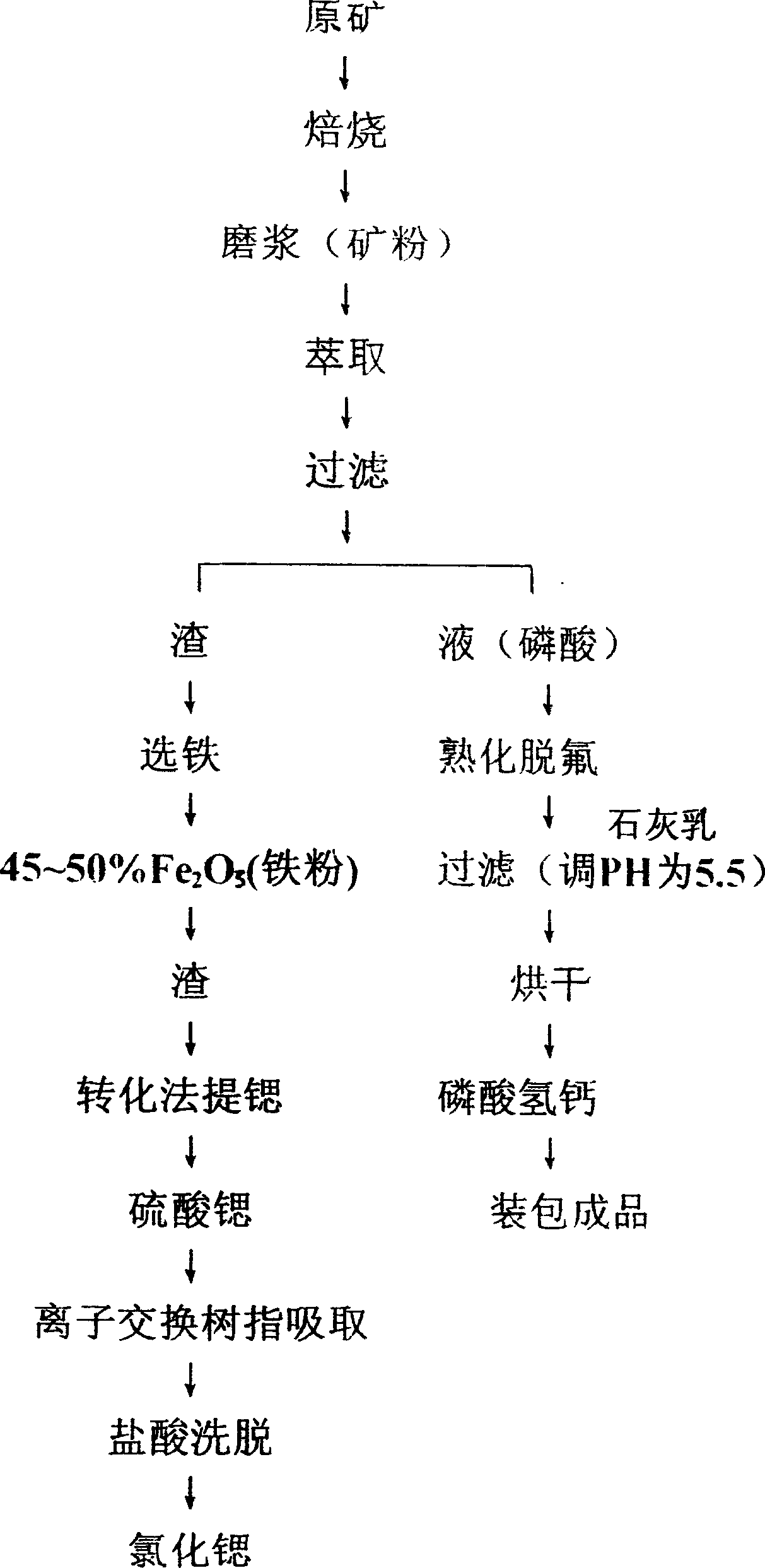

Embodiment 1

[0017] Embodiment one: extract phosphorus test from calcined ore sample, all adopt 120 tons of standard ore sample, P 2 o 5 It is 15% pyrophosphate strontium ore, the ore consumption is 80 grams, the calcination temperature is 600 ° C, the calcination time is three hours, the concentration is 3N sulfuric acid, and the consumption is 384 milliliters. , extraction, extraction and filtration, the liquid and slag are treated separately: the phosphoric acid solution after extraction and filtration is matured and defluorinated, then filtered and adjusted to a pH value of 5.5 with milk of lime, and dried to obtain 24g of feed-grade calcium hydrogen phosphate, which is processed into a finished product Packing; slag after filtering, get 80 grams of 45-50% Fe after iron selection 2 o 3 , the slag after iron selection, extract strontium according to the conversion method, extract strontium carbonate, absorb through ion exchange resin, and get 2g of strontium chloride after elution wit...

Embodiment 2

[0018] Embodiment two: extract phosphorus test from calcined ore sample, all adopt 120 tons of standard ore sample, P 2 o 5 It is 15% pyrophosphate aluminum strontium ore, the ore dosage is 100 grams, the calcination temperature is 650°C, the calcination time is one hour, the concentration is 3N sulfuric acid, and the dosage is 400 milliliters. , extract, extract and filter the liquid and slag separately: the phosphoric acid solution after extraction and filtration is matured and defluorinated, then filtered and adjusted to a pH value of 5.5 with milk of lime, and then dried to obtain 30g of feed-grade calcium hydrogen phosphate for finished product Packing; slag after filtering, get 30 grams of 45-50% Fe after iron selection 2 o 3 , The slag after iron selection, extracts strontium according to the conversion method, extracts strontium carbonate, absorbs it through ion exchange resin, and obtains 3.33 grams of strontium chloride after elution with hydrochloric acid.

Embodiment 3

[0019] Embodiment three: extract phosphorus test from the calcined ore sample, all adopt 120 tons of standard ore samples, P 2 o 5 It is 15% strontium pyrophosphate, the ore consumption is 500 grams, the calcination temperature is 650 ℃, the calcination time is one hour, and the concentration is 3N sulfuric acid, and the consumption is 2 liters to extract. The method is that the raw ore is roasted and refined (ore powder), extract, extract and filter the liquid and slag respectively: the phosphoric acid solution after the extraction and filtration is matured and defluorinated, then filtered and adjusted to pH 5.5 with milk of lime, and then dried to obtain 150kg feed grade calcium hydrogen phosphate. Carry out finished product packing; The slag after filtering, get 150 grams of 45-50% Fe after selecting iron 2 o 3 , the slag after iron selection, extract strontium according to the conversion method, extract strontium carbonate, absorb it through ion exchange resin, and get 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com