Non reversible circuit element and its used wire frame and manufacturing method, communication device

A technology of circuit components and lead frames, applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of poor solder adhesion, rust, short circuit of circuit lines, etc., and achieve good solder adhesion and exclusive area The effect of large and small digging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

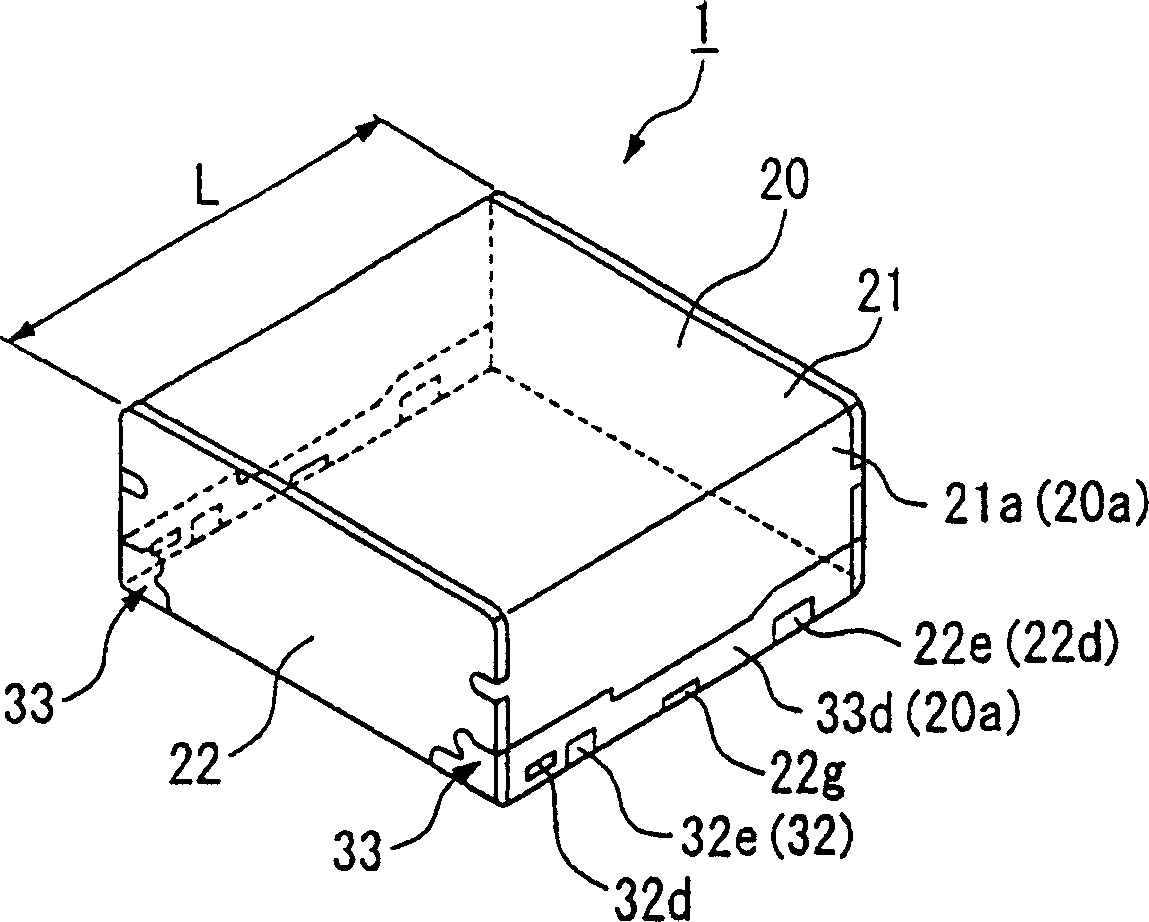

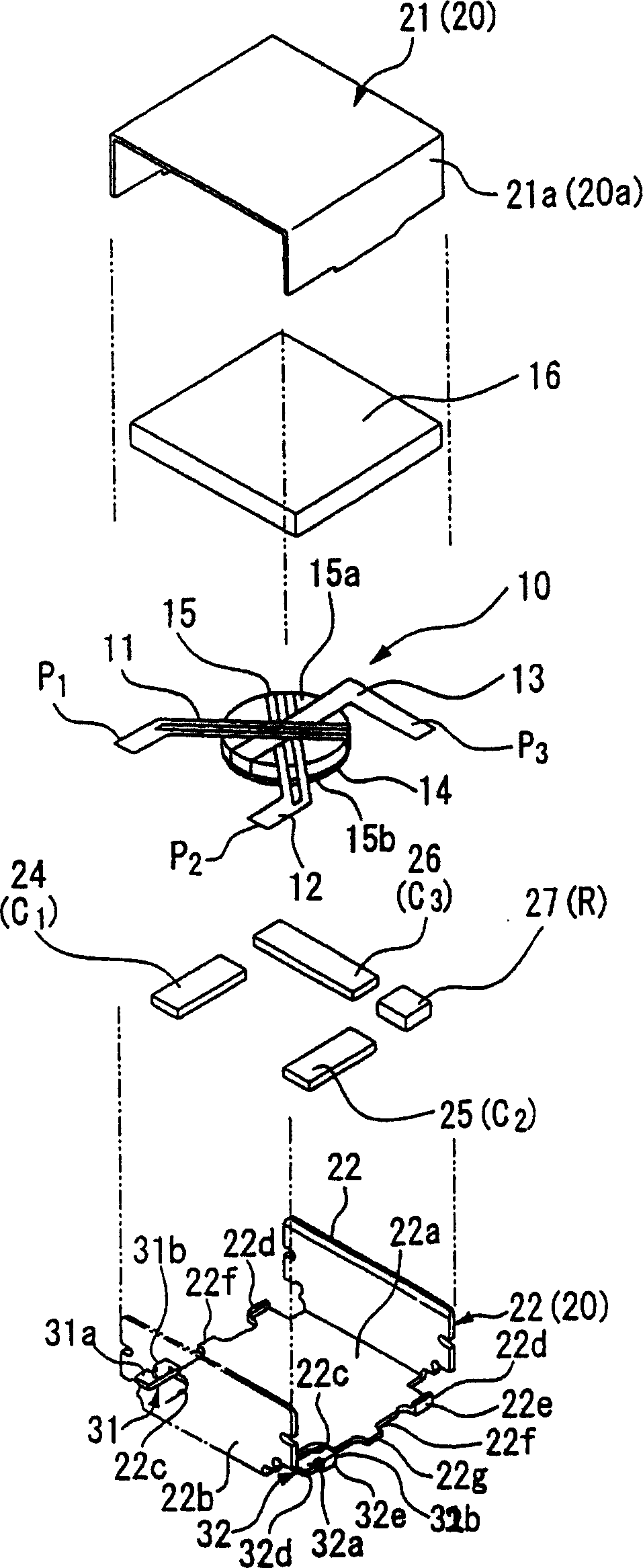

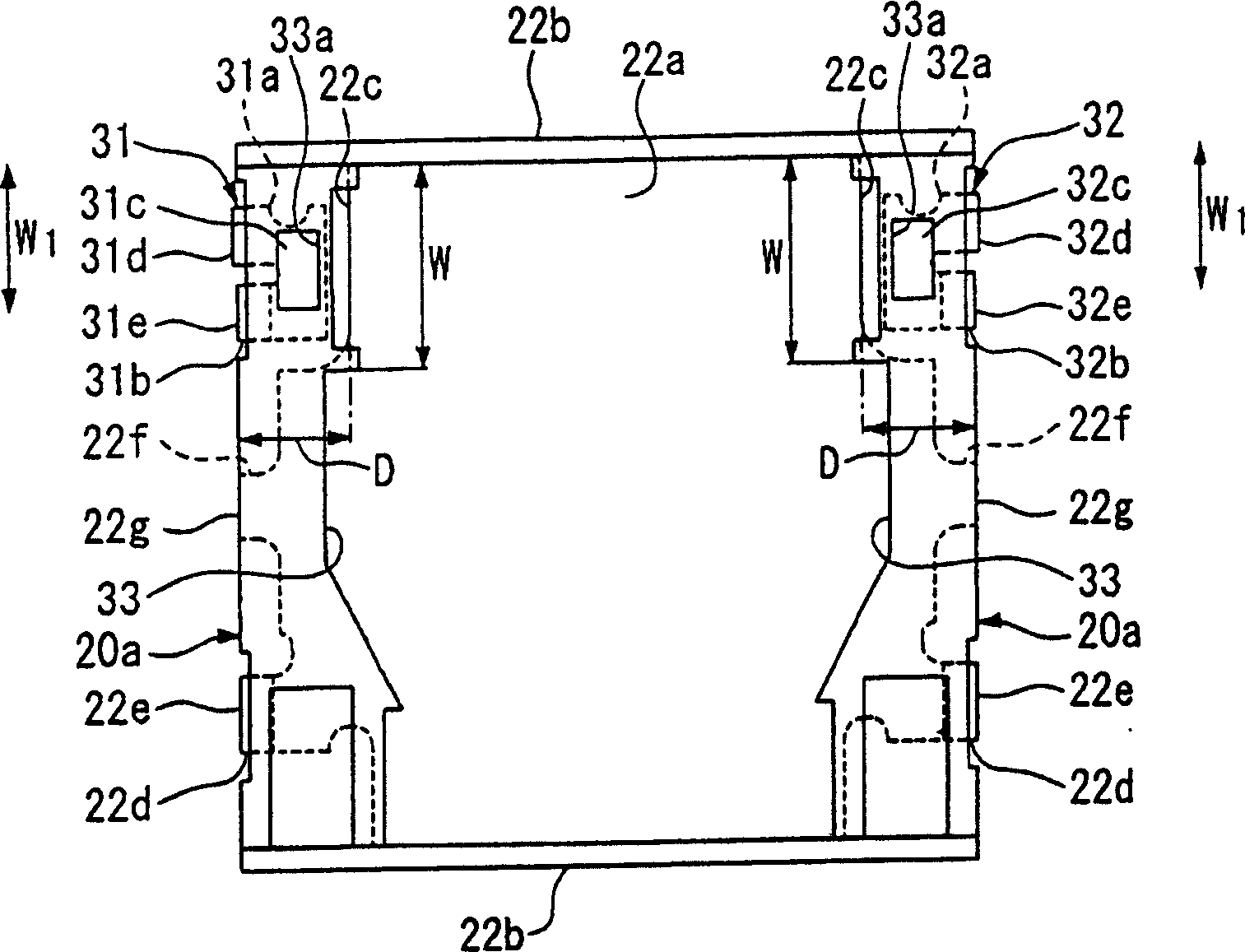

[0073] The relationship between the size of the lower frame gap and the offset magnetic field and out-of-band attenuation of the plate-shaped magnetic body is studied.

[0074] Manufactured an implementation with the same parameters as the above-mentioned embodiment except that the size of the frame is 3.2 mm, the width W of the notch is 0.9 mm, the depth D is 0.2-0.45 mm, and the width W1 in the length direction of the terminal body is 0.6 mm. example isolator. The operating frequency fo of this isolator is set to 1.88GHz. In addition, as the upper frame and the lower frame, Ag-plated pure iron with a thickness of 0.1 mm was used. As the plate-shaped magnetic body, a yttrium-iron-garnet ferrite plate that is deformed hexagonal in plan view is used. The top view shape and size of the plate-shaped magnetic body are: the length of the parallel and opposite long sides is 1.2mm, the lengths of the two opposite sides among the remaining four sides are 0.67mm and 0.98mm respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com