Mask for vacuum deposition and organic el display panel manufactured by using the same

A display panel and mask technology, applied in the direction of electroluminescent light source, vacuum evaporation coating, electric light source, etc., can solve the fine adjustment of tension, the difficulty of removing the mask for evaporation, and the inability to change the mask for evaporation, etc. problem, achieve the effect of preventing offset and deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0074] Such as Figure 6 As shown, as a fixing mechanism, strip-shaped clips 21 are placed on both ends of the mask main body 10 for evaporation along the longitudinal direction of the guide member 12 ( Figure 6 Arrow shown) is fixed in the vertical direction so that it sandwiches the mask frame 11 and the guide member 12.

specific example 2

[0076] Alternatively, use as Figure 7 The shown clips 22 are fixed vertically to the four corners of the vapor deposition mask main body 10 as indicated by arrows, and sandwich the mask frame 11 and the guide member 12 therebetween.

specific example 3

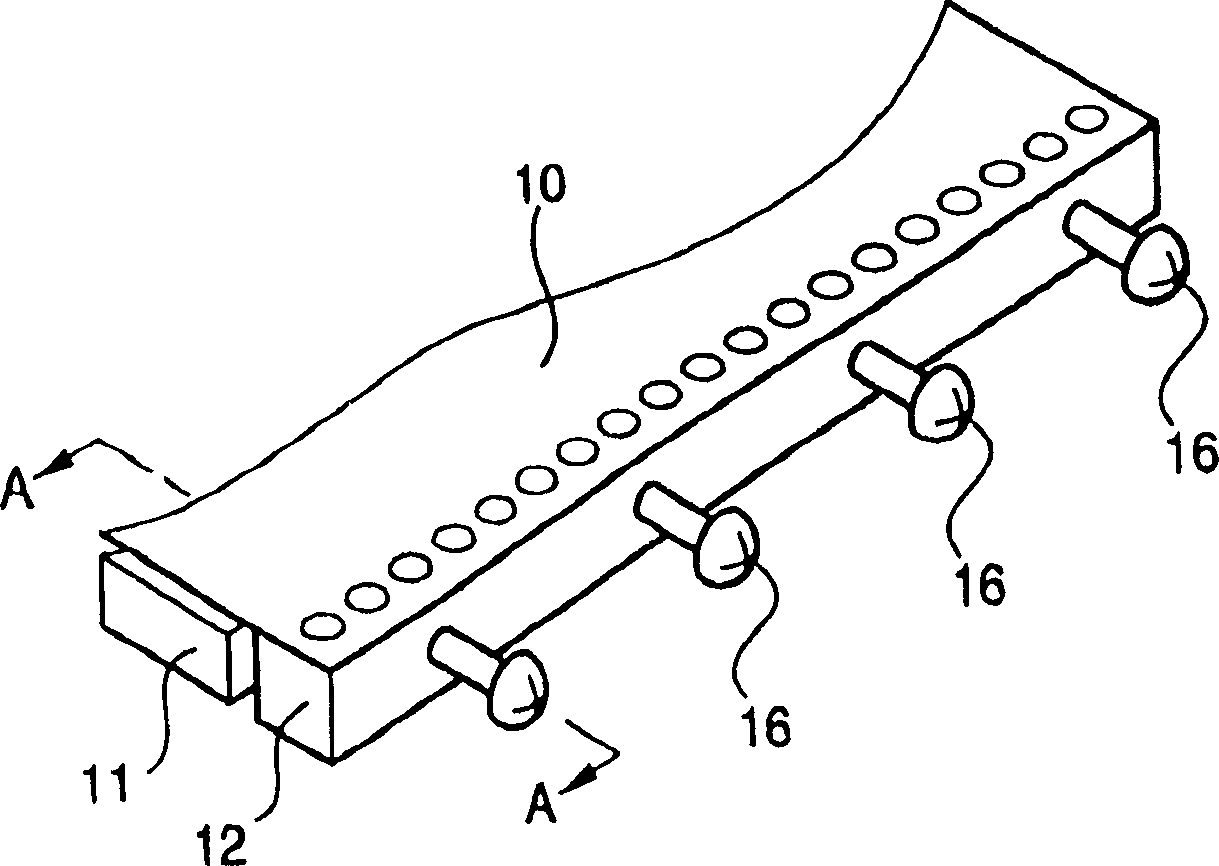

[0078] Figure 8 (a) is a perspective view showing the end of the vacuum deposition mask of Specific Example 3 of the fixing mechanism, Figure 8 (b) is Figure 8 (a) B-B line sectional view.

[0079] Such as Figure 8 (a) and Figure 8 As shown in (b), the fixing mechanism of specific example 3 is provided with a through hole 24 formed on the side wall of the guide member 12 and a through hole formed in the mask between the screw members 16, 16 installed on the side of the guide member 12. Holes 25 on the sides of the frame 11 are fixed in the vertical direction by inserting pins 23 through these through holes 24 and holes 25 .

[0080] In addition to the above-mentioned fixing mechanism, it is also possible to insert a screw through a through hole formed in a vertical direction relative to the mask surface of the mask frame 11 and screw its front end into the mask surface relative to the guide member 12. The guide member 12 is fixed in the vertical direction relative to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com