Edible mushroom capsule and capsule mushroom and production method thereof

A technology of capsule strains and edible fungi, applied in botany equipment and methods, fungal products, applications, etc., can solve problems such as inaccurate inoculation, contamination of culture bags with bacteria, inconvenient transportation of strains, etc., to save Disinfection and sterilization time, less contamination by bacteria, consistent loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with accompanying drawing:

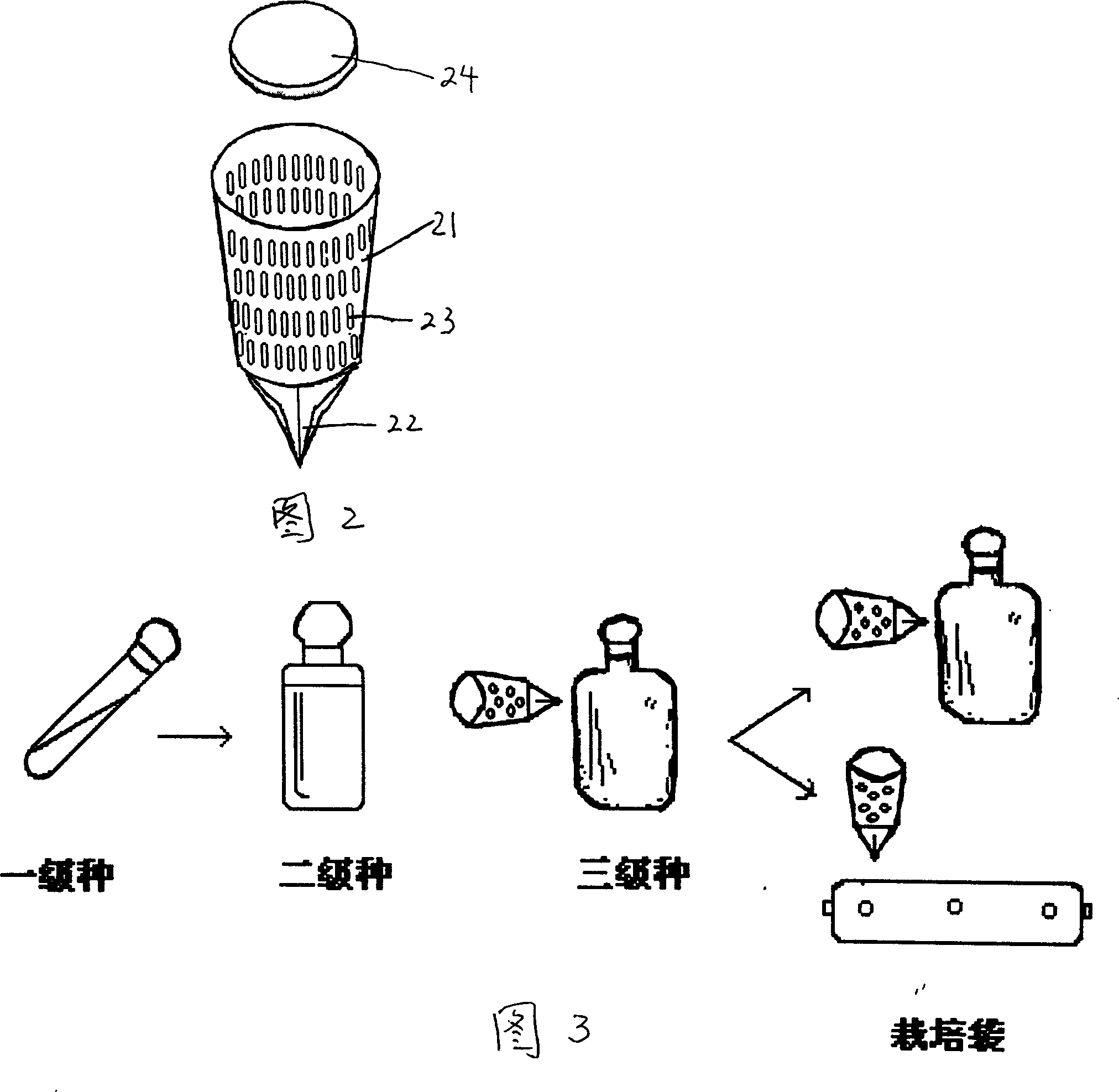

[0013] As shown in Fig. 2, the edible fungus capsule of the present invention, its capsule body 21 is conical shape, and front end portion has spike-shaped head 22, for being beneficial to directly stabbing into the culture bag that is inoculated, spike-shaped head is Triangular or quadrangular shape; through-holes 23 are opened on the wall of the capsule body 21, and these through-holes are evenly arranged round or rectangular with rounded corners. The capsule body is formed by injection molding of degradable low-pressure polyethylene or high-pressure polypropylene, and its size can be (20---17)*(25---30)*0.2mm. The capsule strain of the present invention, it is that culture medium is packed in the capsule body 21, seals with cover 24 above, and inserts strain in it.

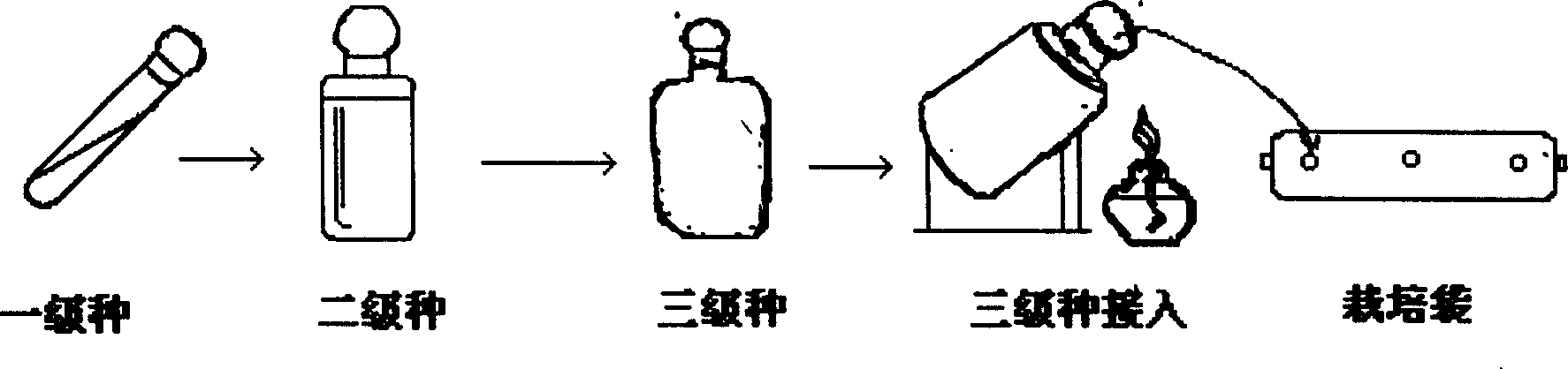

[0014] The production method of the capsule strain of the present invention is shown in Fig. 3, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com