Intelligent control method for die hammer and intelligent die hammer produced according to said method

A technology of intelligent control and die forging hammer, applied in the driving device of hammer, forging/pressing/hammer device, hammer, etc., can solve the problems of reducing the quality of forgings, strong vibration of striking energy, high labor intensity, etc., and achieve the service life of the die Realize, reduce energy waste, improve the effect of forging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

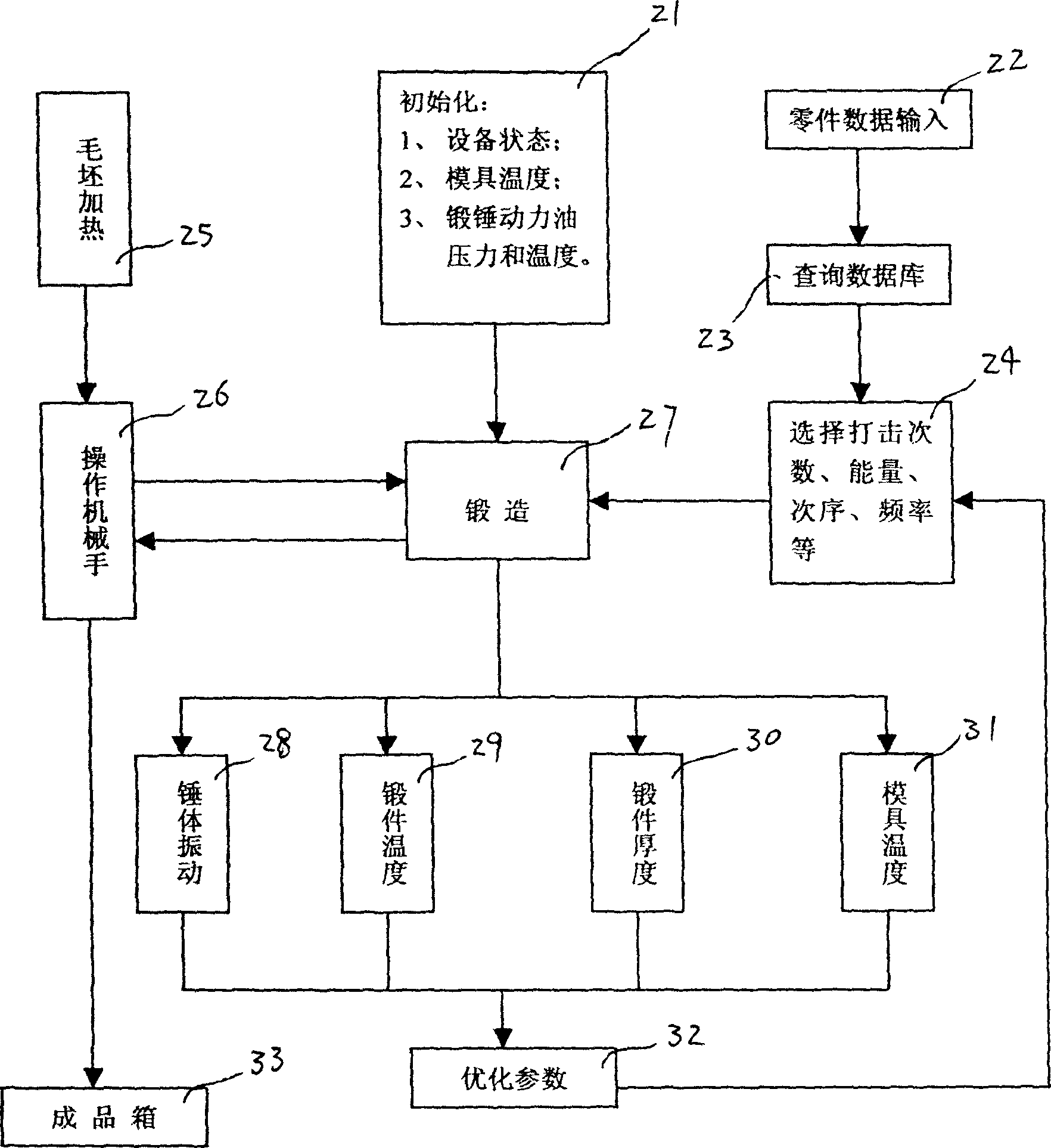

[0024] figure 1 The intelligent control method of the die forging hammer of the present invention is described. When the intelligent die forging hammer is working, it first performs initialization work 21, including parameters such as equipment status, mold temperature, forging power oil pressure and temperature, and cleanliness, so that it is within the normal working range, and then enters the data of forging blanks and finished forgings 22 , the expert system queries the database 23 according to the main parameters such as forging material, size, deformation degree, etc., and thus initially sets the number of strikes, energy, sequence, frequency 24, etc. The forging blank is heated 25 by the heating device, and when it reaches the initial forging temperature, it is released from the furnace, and a signal is sent to the manipulator 26, and the manipulator automatically moves the workpiece to the predetermined cavity for striking 27. After striking process is finished, opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com