Metalloporphyrin synthesizing method

A synthesis method, metalloporphyrin technology, applied in the field of metalloporphyrin synthesis, can solve problems such as difficult product separation, low yield of μ-oxygen double metalloporphyrin, metal ion shedding, etc., and achieve the effect of reducing synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

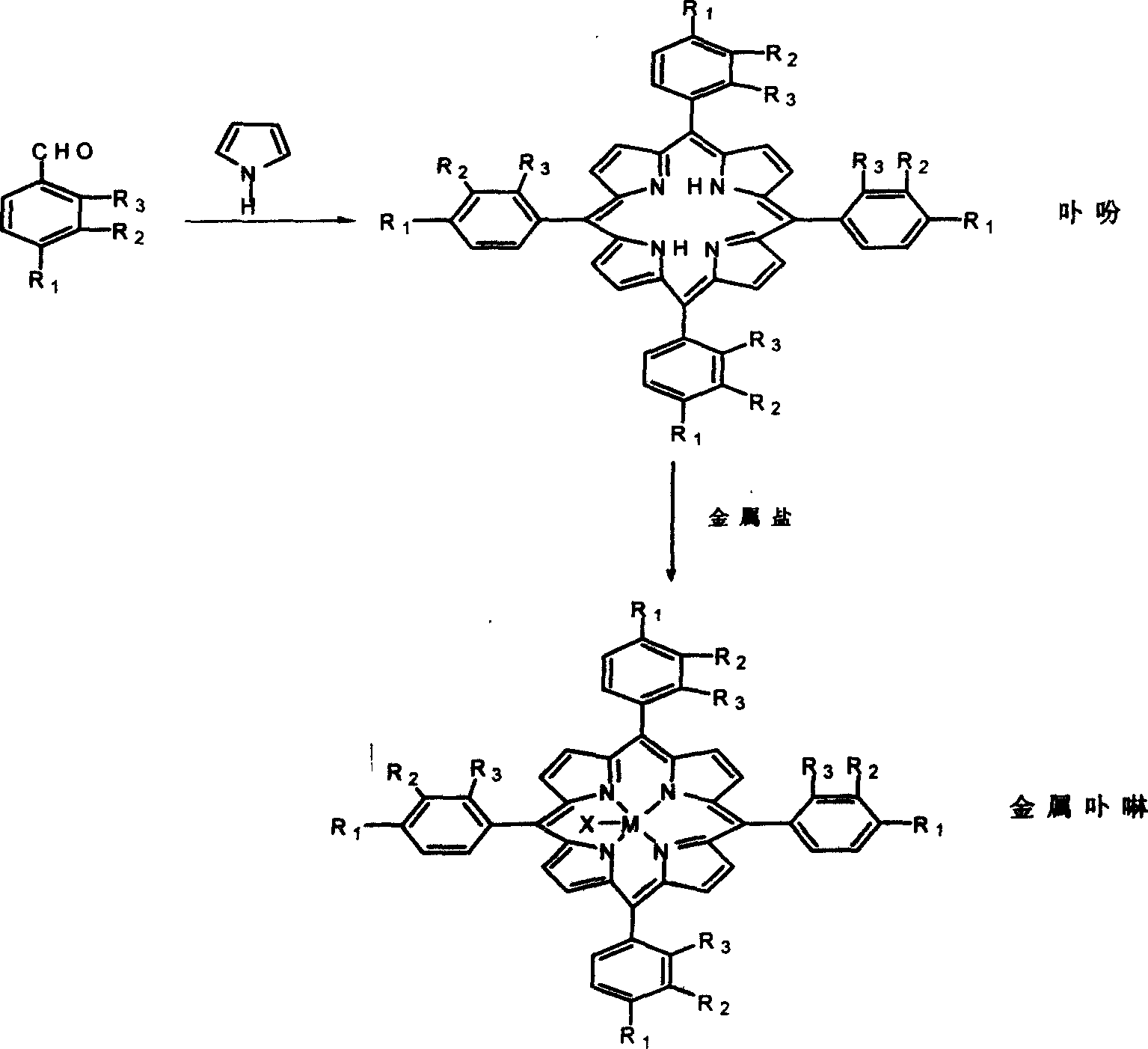

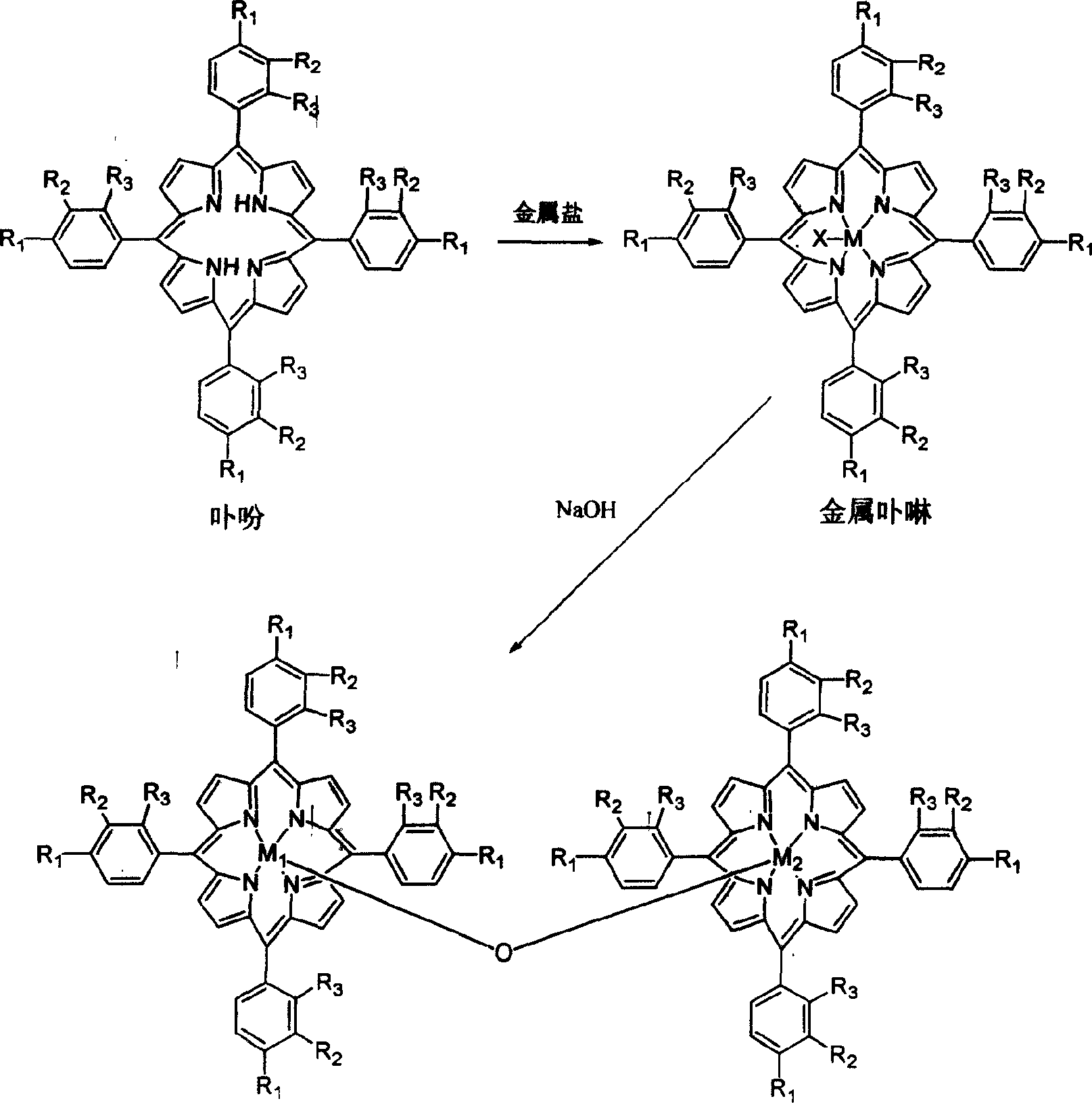

Method used

Image

Examples

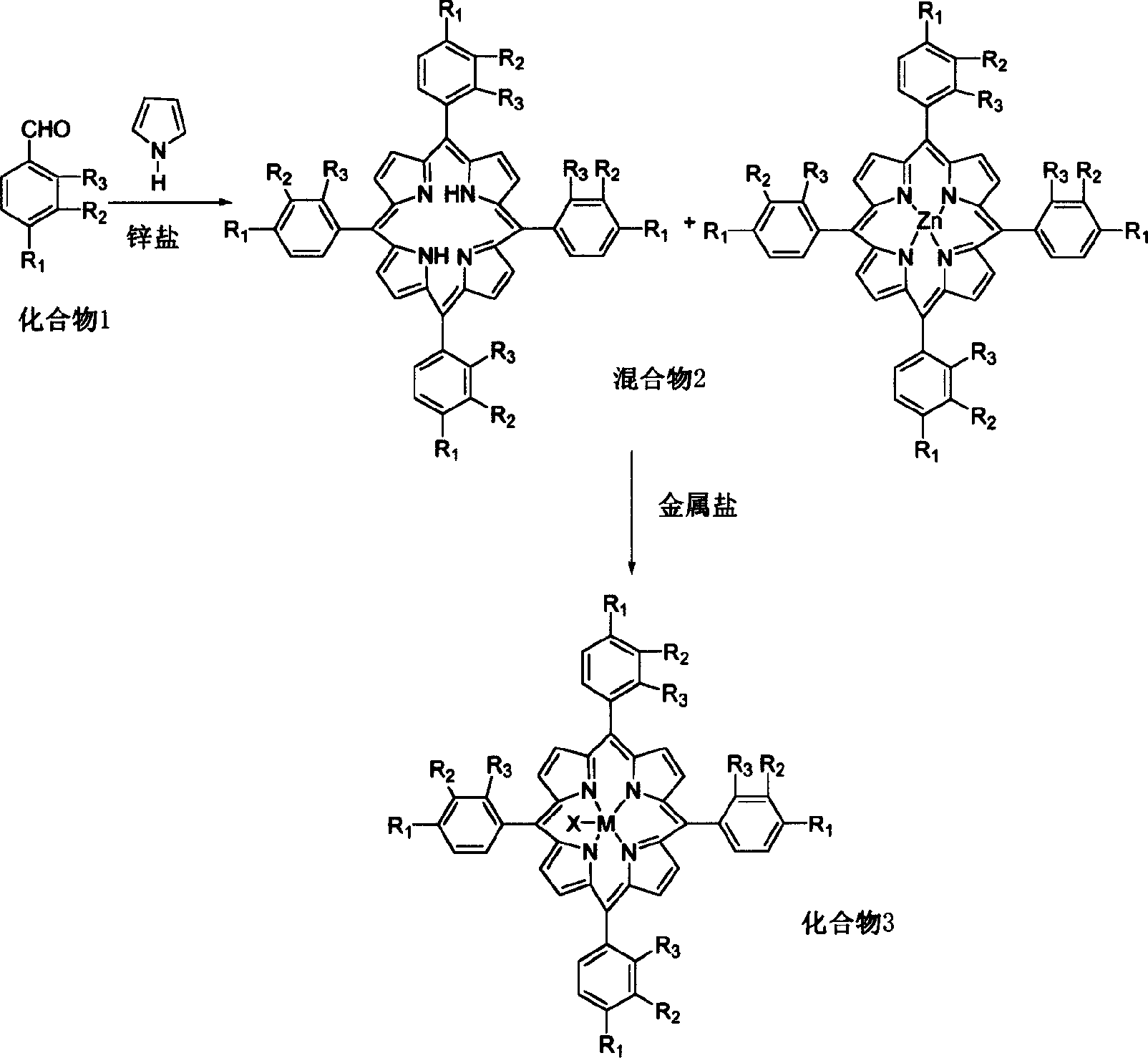

Embodiment 1

[0030] Embodiment 1: 5g compound 1, R 1 =OCH 3 , R 2 = R 3 =H, and 4g pyrrole, 5gZnCl 2 , was added in 100ml of propionic acid, and the reactant was stirred under reflux for 0.5 hour, cooled and separated to obtain a mixture 2.

[0031] The resulting mixture 2 was dissolved in refluxing xylene and 1 g Co(acac) was added 2 , reacted for 2 hours to obtain compound 3 (M=Co, R 1 =OCH 3 , R 2 = R 3 = H). The conversion of compound 1 was 30% and the conversion of mixture 2 was 95%.

Embodiment 2

[0032] Embodiment 2: with 5g compound 1, R 1 =OH, R 2 = R 3 =CH 3 , and 4g pyrrole, 5gZnCl 2 , was added to 120ml of acetic acid, and the reactant was stirred under reflux for 1 hour, cooled and separated to obtain a mixture 2.

[0033] The resulting mixture 2 was dissolved in refluxing chloroform / DMF and 1 g Cu(OAc) was added 2 , reacted for 2 hours to obtain compound 3 (M=Cu, R 1 =OCH 3 , R 2 = R 3 = H). The conversion of compound 1 was 35% and the conversion of mixture 2 was 94%.

Embodiment 3

[0034] Embodiment 3: 5g compound 1, R 1 =N(CH 3 ) 2 , R 2 = Cl, R 3 =CH 3 , and 4g pyrrole, 5gZn(OAc) 2 , was added to 120ml of acetic acid, and the reactant was stirred under reflux for 1 hour, cooled and separated to obtain a mixture 2. The resulting mixture 2 was dissolved in refluxing chloroform / DMF and 1 g NiCl was added 2 , reacted for 1.5 hours to obtain compound 3 (M=Ni, R 1 =N(CH 3 ) 2 , R 2 = Cl, R 3 =H). The conversion of compound 1 was 32% and the conversion of mixture 2 was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com