Pyrotechnic composition for thermal pipe cutter and process for making same

A production process and technology of pyrotechnics, applied in wellbore/well components, earthwork drilling and production, etc., to achieve the effect of convenient transportation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

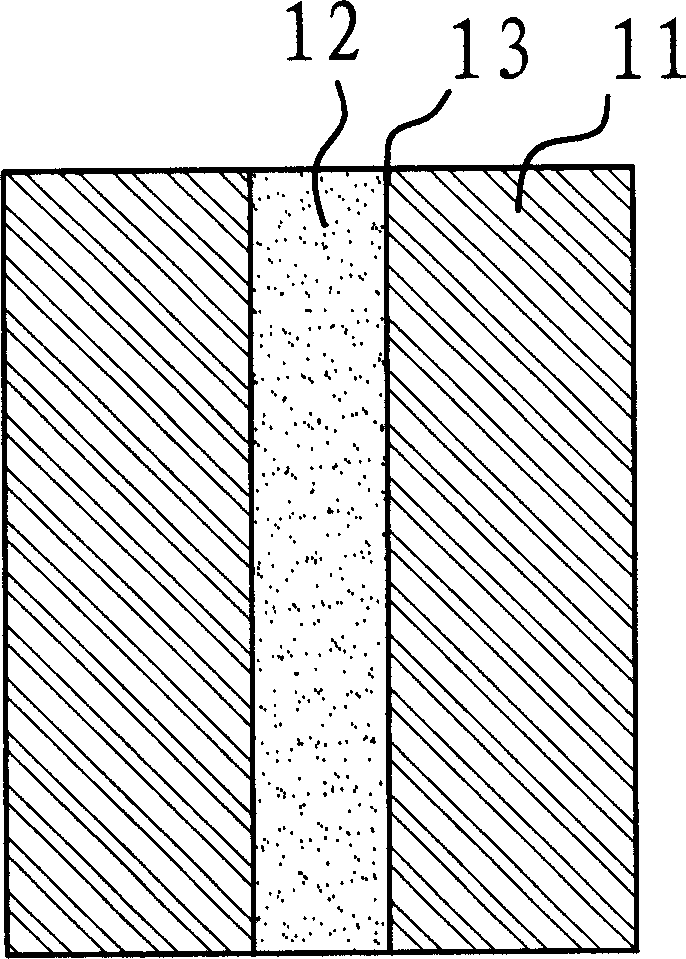

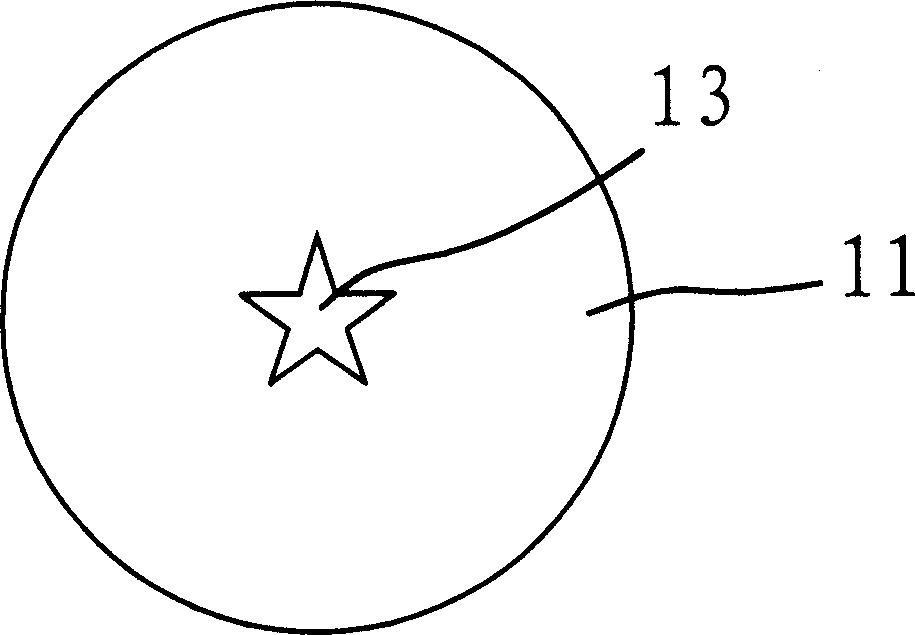

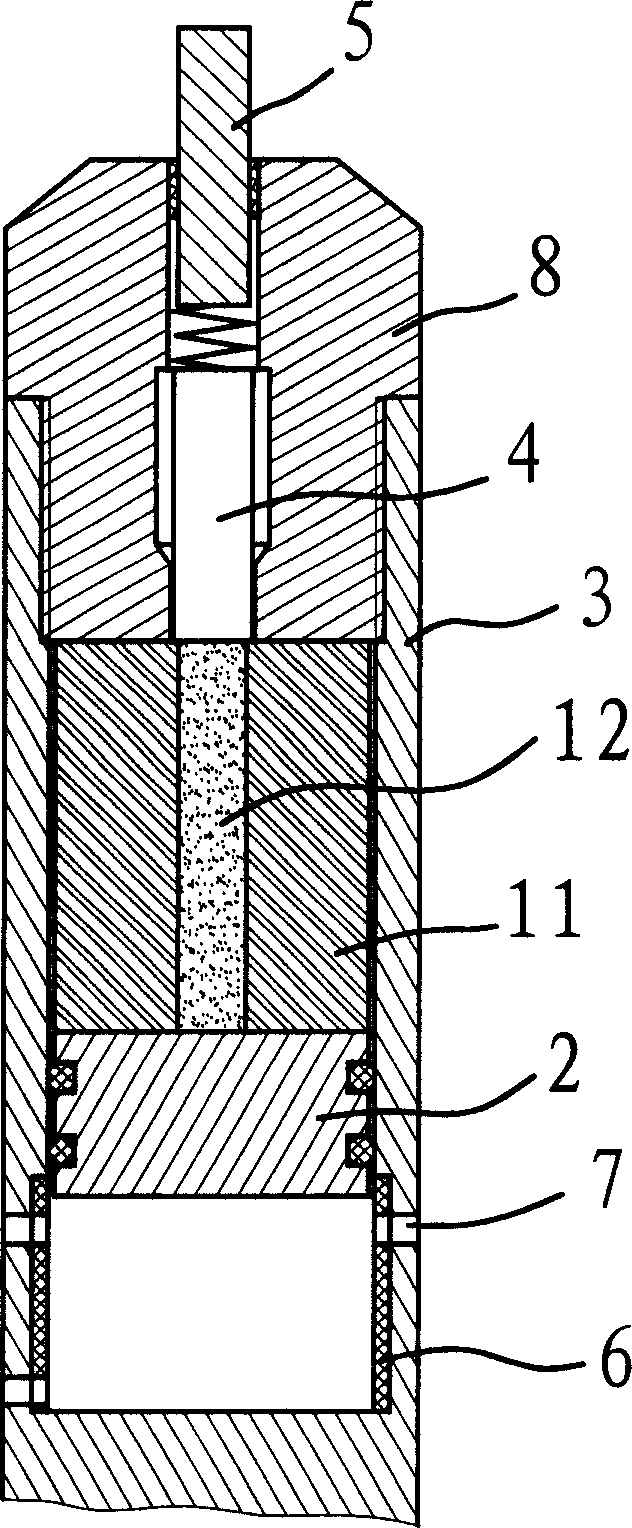

[0027] First, mix 100 grams of aluminum powder and 300 grams of ferric oxide to make 400 grams of thermite. The thermite was mixed with 100 grams of gas forming agent. In this embodiment, the gas-forming agent is selected from nitrocellulose. This gives a powdery mixture. Then this mixture is put into the mold and pressed into a columnar body with an inner hole 13 in the center, that is, the pyrotechnic agent outer layer 11, such as figure 2 shown. Finally, the above-mentioned mixture that has not been compressed is loaded into the inner hole to become the pyrotechnic inner layer 12 .

[0028] like figure 1 and figure 2 As shown, in this embodiment, the density of the outer layer 11 of the pyrotechnic agent is relatively large, at 3.6g / cm 3 about. The density of the inner layer 12 is relatively small, at 1.7g / cm 3 about.

[0029] like figure 2 As shown, the cross-sectional shape of the pyrotechnic charge inner hole 13 is star-shaped. This is beneficial to increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com