Article sterilizing methods and sterilizing device

A technology for sterilizing devices and articles, applied in the directions of transportation and packaging, packaging, bottling machines, etc., can solve problems such as poor heat resistance, deformation, and bottle heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

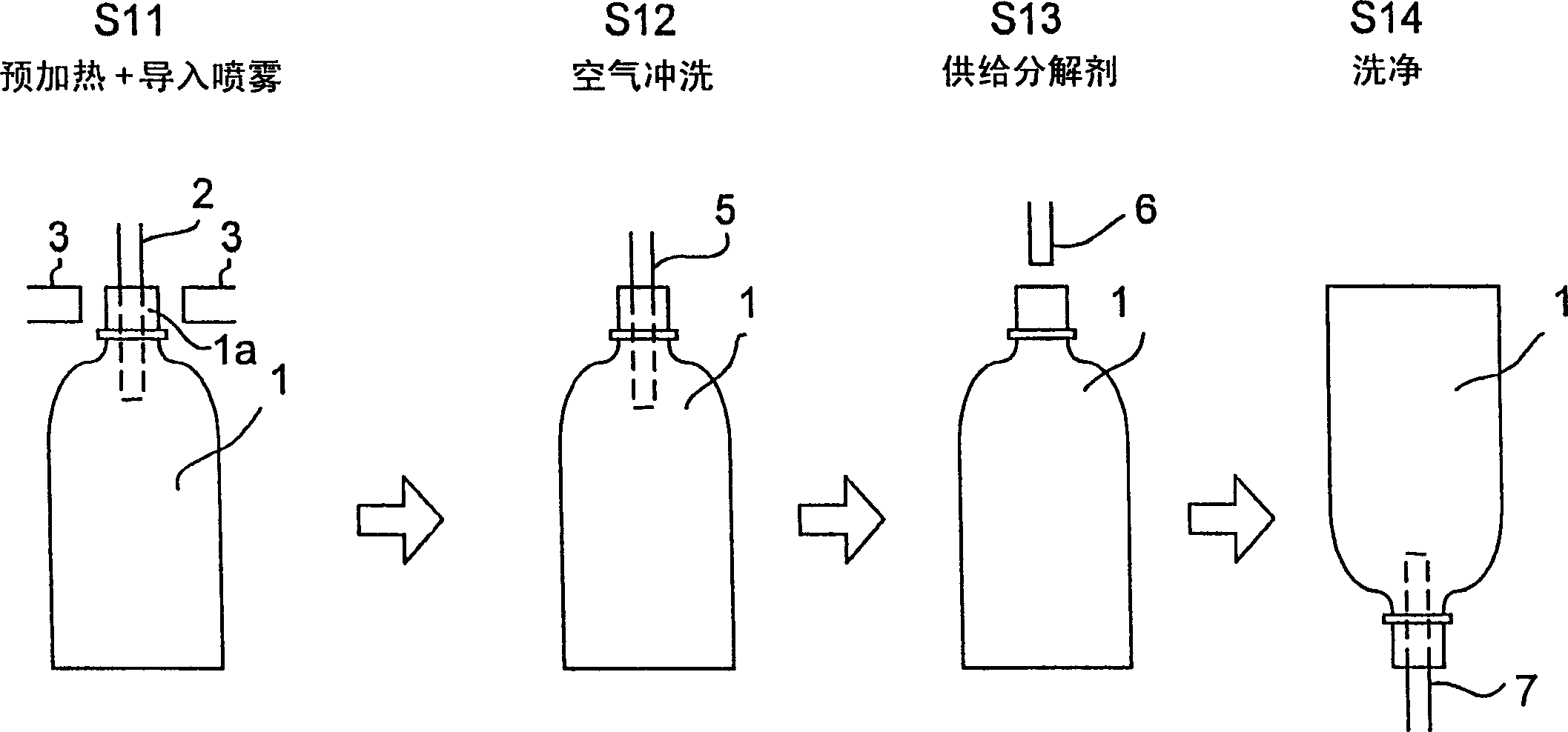

[0026] figure 1 It is a figure which shows the procedure of the sterilization method of Embodiment 1 of this invention. This embodiment shows a method of sterilizing the inner surface of a PET (polyethylene terephthalate) bottle. In this sterilization method, first, a preheating treatment is performed (step S11). In the preheating, the nozzle 2 is inserted into the inside from the mouth 1 a of the bottle 1 , and hot air is blown from the nozzle 2 to preheat the bottle 1 . At the same time, nozzles 3, 3 are provided on the outer periphery of the mouth 1a of the bottle 1, and hot air is blown from these nozzles 3 to the mouth 1a to heat the mouth 1a again. And, the process of introducing the spray of the sterilizing agent into the bottle 1 is performed simultaneously with the preheating process. The spray is introduced by mixing the spray with hot air supplied for preheating.

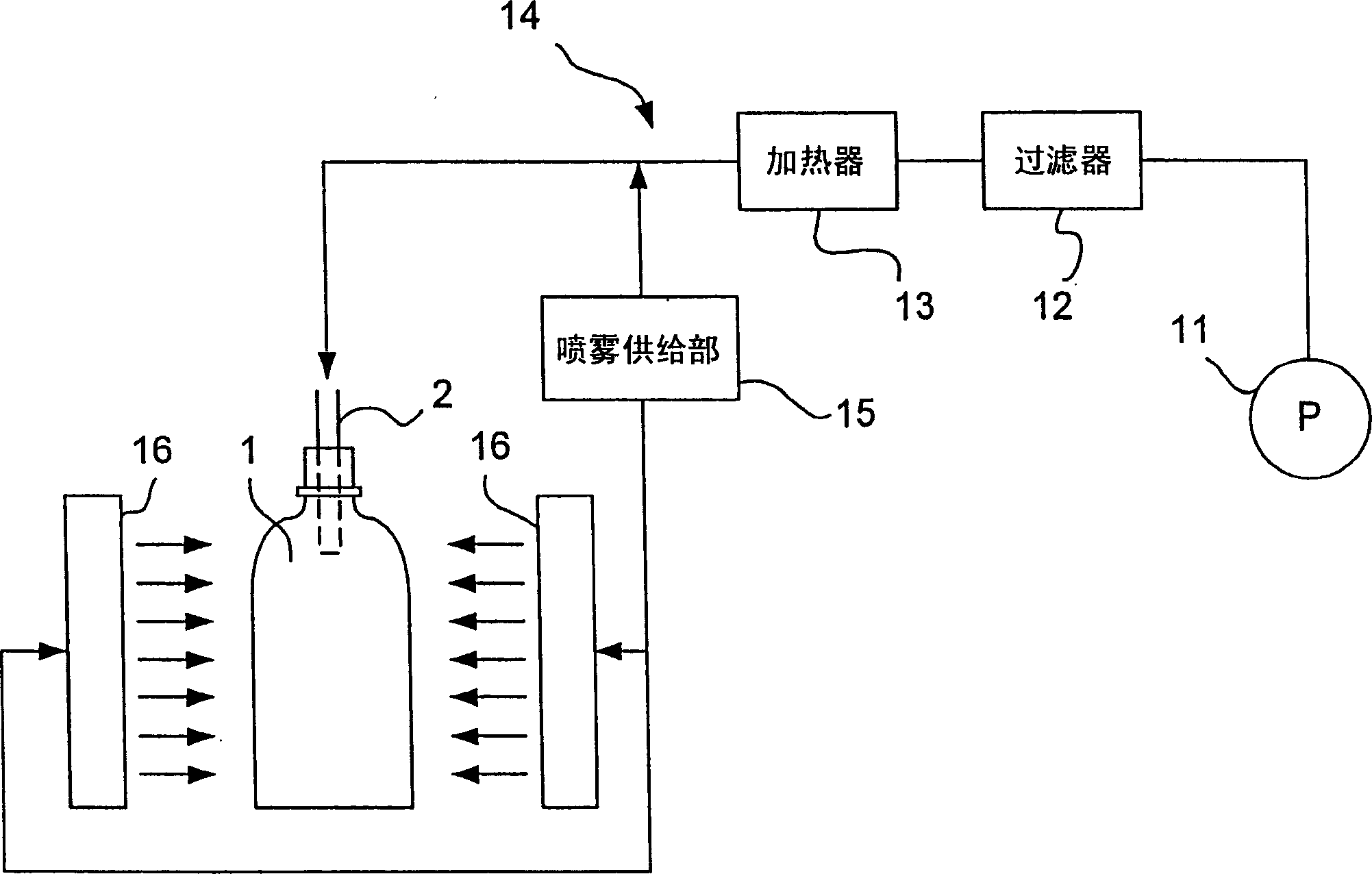

[0027] figure 2 It is a schematic diagram showing the equipment used in the preheating and spray...

Embodiment approach 2

[0041] Figure 4 It is a figure which shows the procedure of the sterilization method of Embodiment 2 of this invention. In this embodiment, PET bottles are also used as articles to be sterilized.

[0042] exist Figure 4 In the sterilizing method of the method, a preheating treatment is first carried out (step S21). In the preheating, the nozzle 2 is inserted into the inside from the mouth 1a of the bottle 1, and the bottle 1 is preheated by blowing hot air from the nozzle 2, and at the same time, the treatment of spraying the disinfectant into the bottle 1 is performed in parallel with the preheating treatment. . The introduction of the spray is done by using figure 2 The shown device is realized by mixing and spraying hot air for preheating.

[0043] In addition, in Figure 4 In the sterilization method, instead of figure 1 The shown nozzle 3 preheats and sterilizes the outer surface of the mouth portion 1a of the bottle 1 by the guide member 20 provided on the nozz...

Embodiment 1

[0057] A 500ml PET bottle was sterilized according to the procedure of Embodiment 1. The specific sterilization sequence is as follows.

[0058] (1) From a nozzle with an inner diameter of 10mm to 0.5m 3 The air volume per minute is introduced into the bottle with hot air at a temperature of 105-125°C at the nozzle opening. At this time, 35% hydrogen peroxide is vaporized at a rate of 80 to 400 g per minute to generate a bactericide spray, which is mixed with hot air and introduced into the bottle.

[0059] (2) Then, the supply of hot air was stopped, and after 0.5 to 3.5 seconds, hot air was blown into the inside of the bottle for 1 second under the same conditions as preheating (but without mixing spray).

[0060] (3) The supply of hot air was stopped, and 1 ml of a 500 U / ml catalase aqueous solution was sprayed into the inside of the bottle after 1 second.

[0061] (4) After 5 seconds, the bottle was turned over, and sterile water heated to 70° C. was sprayed into the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com