In-situ sludge improvement method and sludge planting soil

A technology of silt and improver, which is applied in the direction of planting substrates, chemical instruments and methods, botany equipment and methods, etc., can solve the problems of silt covering a large area, pollution transfer, long treatment cycle, etc., to reduce treatment costs, treat High efficiency, reducing the effect of pollutants and the total number of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

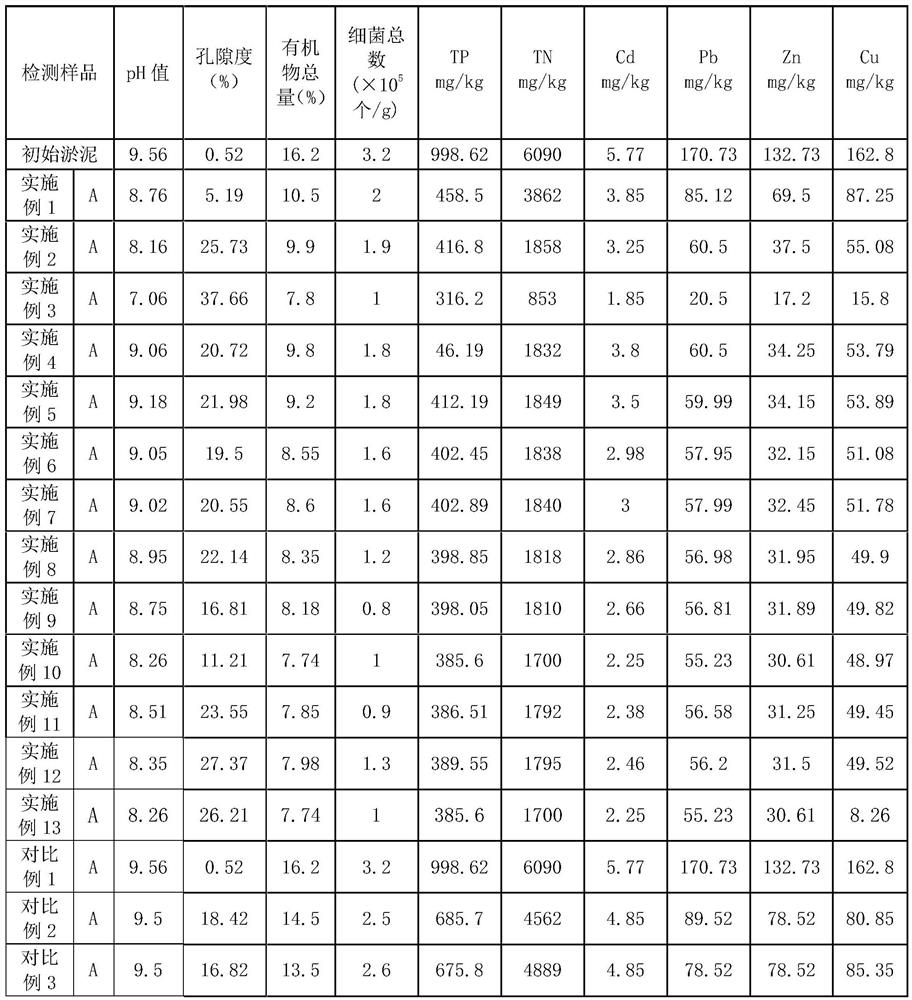

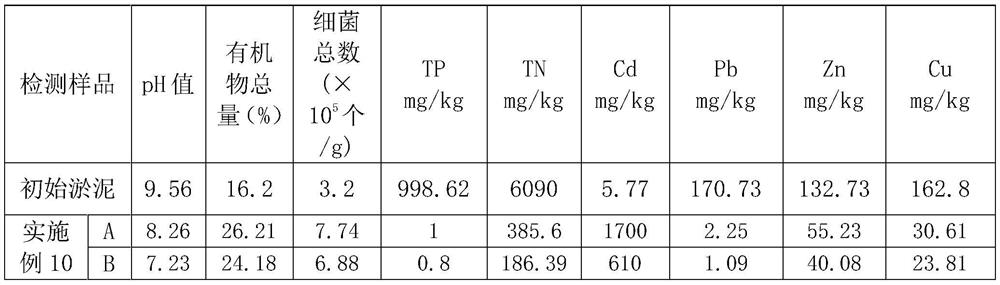

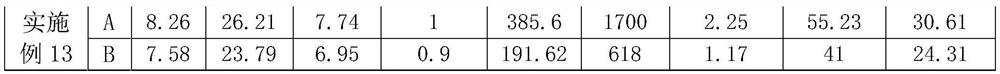

Examples

preparation example

[0041] The preparation of sludge modifier is as follows:

[0042] Mix river sand, coconut peat, branch particles, volcanic rock filter material and deodorant uniformly according to the formula ratio to prepare the silt modifier. Wherein, by volume ratio, the silt particles: river sand: coconut bran: branch particles: volcanic stone filter material: deodorant=(3-8):(2-5):(1-3):(1- 3):(1-2):(1-3). The deodorant is selected from traditional Chinese medicine dregs or tea dregs.

preparation example 1

[0044] The total volume of the silt conditioner is 1m 3 , by volume ratio, river sand: coconut peat: branch particles: volcanic rock filter material: traditional Chinese medicine slag=6:5:4:3:1.

preparation example 2

[0046] The total volume of the silt conditioner is 1m 3 , by volume ratio, river sand: coconut peat: branch particles: volcanic rock filter material: traditional Chinese medicine residue = 2:1:1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com