Method for producing fresh-cut fruits and vegetables through high pressure carbon dioxide technology

A high-pressure carbon dioxide, fruit and vegetable technology, applied in the field of biomedicine, can solve the problems of product color, aroma, shape and nutrition, promote the rapid reproduction of microorganisms, and the obvious blasting effect of products, so as to weaken the blasting effect, retain structure and quality, reduce Effect of Product Bacteria Count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

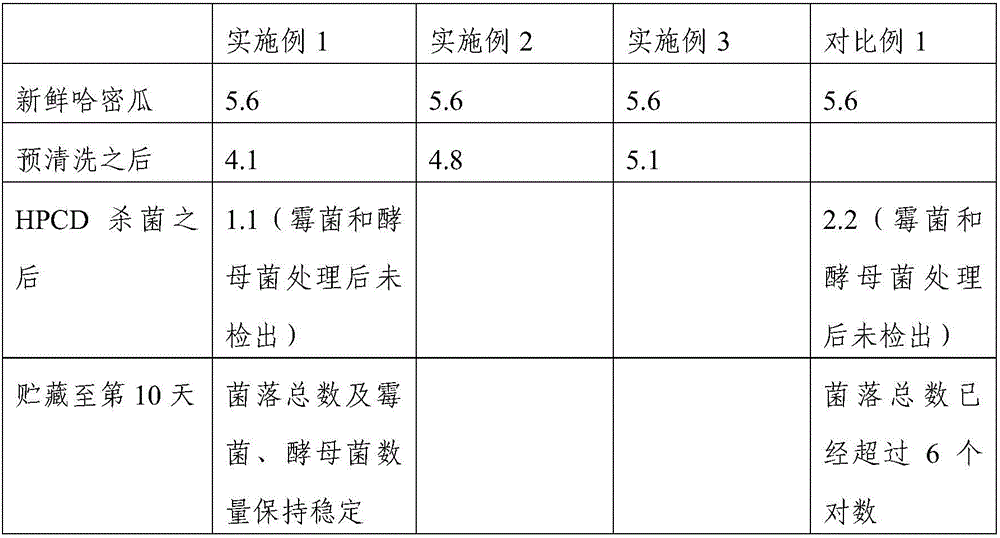

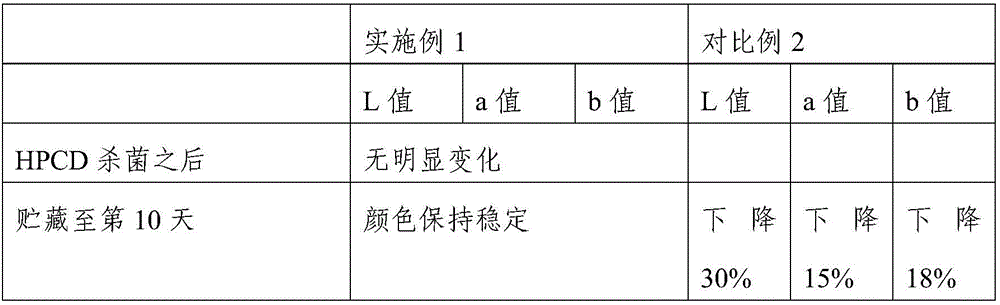

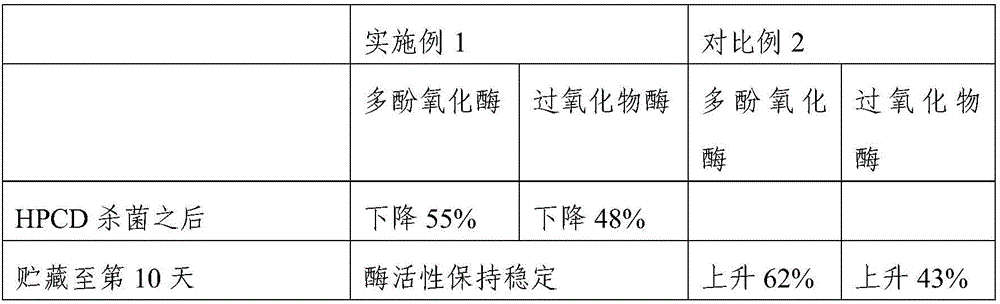

Embodiment 1

[0033] Embodiment 1 The production method of fresh-cut Hami melon

[0034] (1) Select fresh ripe cantaloupes with no pests, no mechanical damage, and uniform size, wash the peel with tap water, and cut into 2cm×2cm×2cm blocks.

[0035] (2) Put Hami melon in 50ppm ClO 2 solution, ultrasonically cleaned for 15 min.

[0036] (3) Use 75% ethanol to sterilize the sterilization chamber of the high-pressure carbon dioxide equipment, place Hami melon in the sterilization chamber of the high-pressure carbon dioxide sterilization equipment, close the sterilization chamber, set the pressure and time parameters, and process at room temperature;

[0037] The treatment pressure is 4MPa, the treatment time is 10min, the average pressure increase rate is 2MPa / min, and the average pressure relief rate is 3MPa / min;

[0038] (4) After the treatment, put the Hami melon in a pre-sterilized packaging bag / box, seal it, and refrigerate it at 4°C.

Embodiment 2

[0040] Fresh-cut Hami melons were prepared in a method similar to that of Example 1, except that the cleaning solution was electrolyzed water with a chlorine concentration (ACC) of 50 ppm.

Embodiment 3

[0042] Fresh-cut Hami melons were prepared in a method similar to that of Example 1, except that the cleaning solution was tap water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com