Process and device for pretreating fresh-care cold fresh pork by combination of ozone water and alcohol

A technology of ozone water and pretreatment, which is applied in the field of slaughtering and disinfection technology and its devices, can solve the problems of polluted meat, unobvious reduction of the number of original bacteria, and decline of meat quality, so as to reduce the total number of bacterial colonies, better sensory quality, The effect of prolonging the storage shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

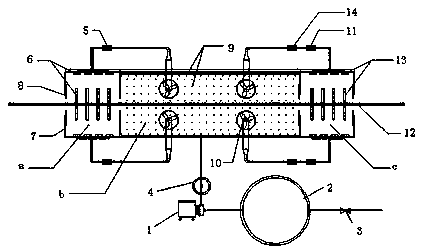

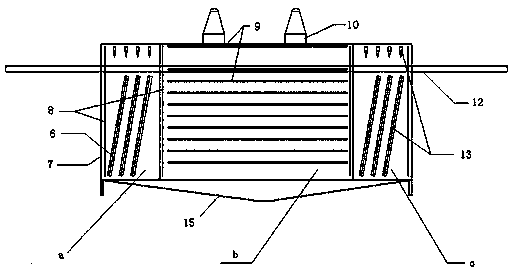

[0043] The current production process of chilled fresh pork is: shower→electric anesthesia→bleeding→washing pig→head removal→peeling→primary showering→laparotomy→evisceration→halving→segmentation→cooling→packaging.

[0044] Ozone water-ethanol joint pretreatment process for fresh-keeping chilled pork:

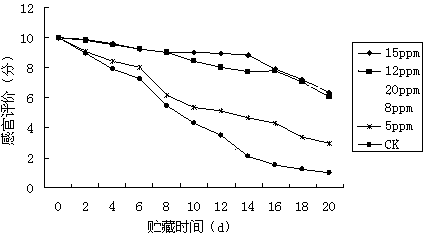

[0045] (1) Preparation of chilled fresh pork slices: After live chilled fresh pork is killed by electric shock, the head, tail, skin and viscera are removed, rinsed with clean water, and sliced. Respectively after peeling and splitting in half, rinse with ozone water with a concentration of 5ppm, 8ppm, 12ppm, 15ppm, 20ppm and spray disinfection in combination with ethanol. The mass concentration of ethanol is 75%. Ozone water adopts the device in the specific embodiment to flush, and ethanol adopts conventional spraying device to carry out disinfection.

[0046] (2) Packaging and storage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com