Suction unit for use in an electric vacuum cleaner and electric vacuum cleaner employing same

A vacuum cleaner and vacuum head technology, applied in vacuum cleaners, suction nozzles, applications, etc., can solve problems such as electric shock, fire, and harmful by-products such as ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] With the help of Figure 1 to Figure 9 The first embodiment of the present invention will be described.

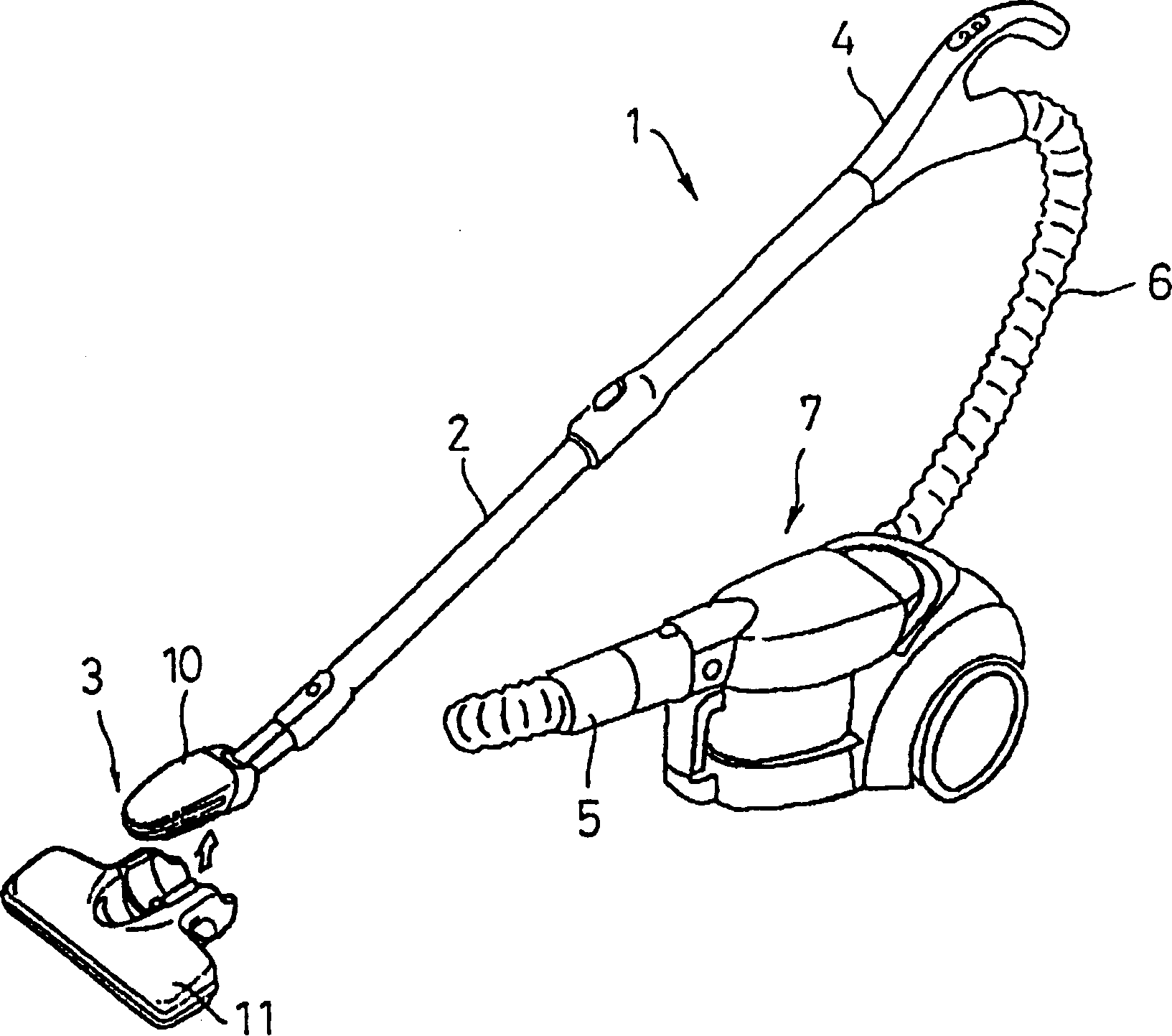

[0033] This example shows figure 1 The ground mobile electric vacuum cleaner 1 shown in and the dust suction head 3 as its dust suction port. In the electric vacuum cleaner 1, the dust suction head 3 is mounted on the front end of the extension tube 2 in a detachable manner, and the other end of the extension tube 2 is connected with the armrest handle (handrail operating rod) 4, and the soft handle extending from the armrest handle 4 The pipe 6 is connected to the main body 7 of the vacuum cleaner through a hose joint 5 .

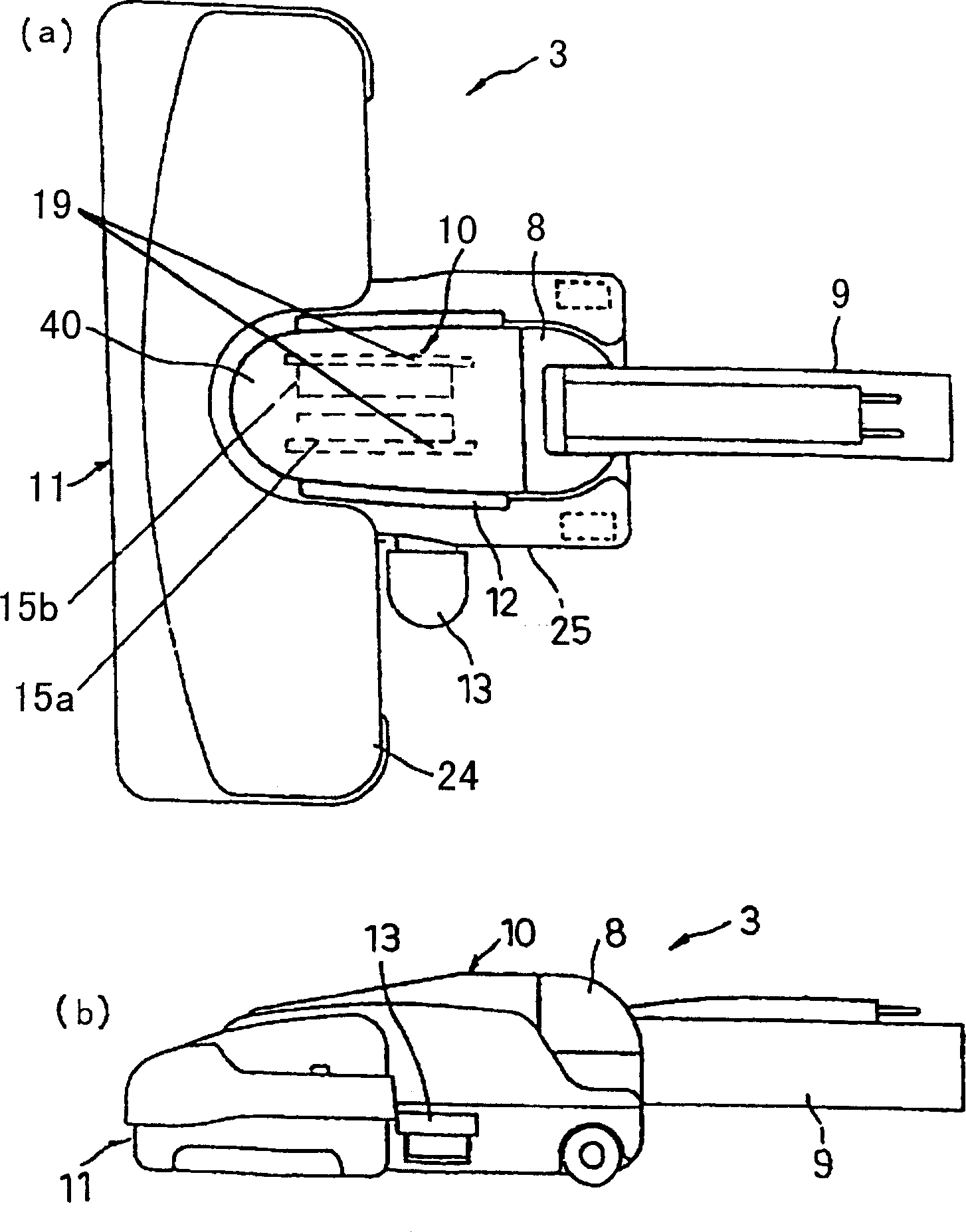

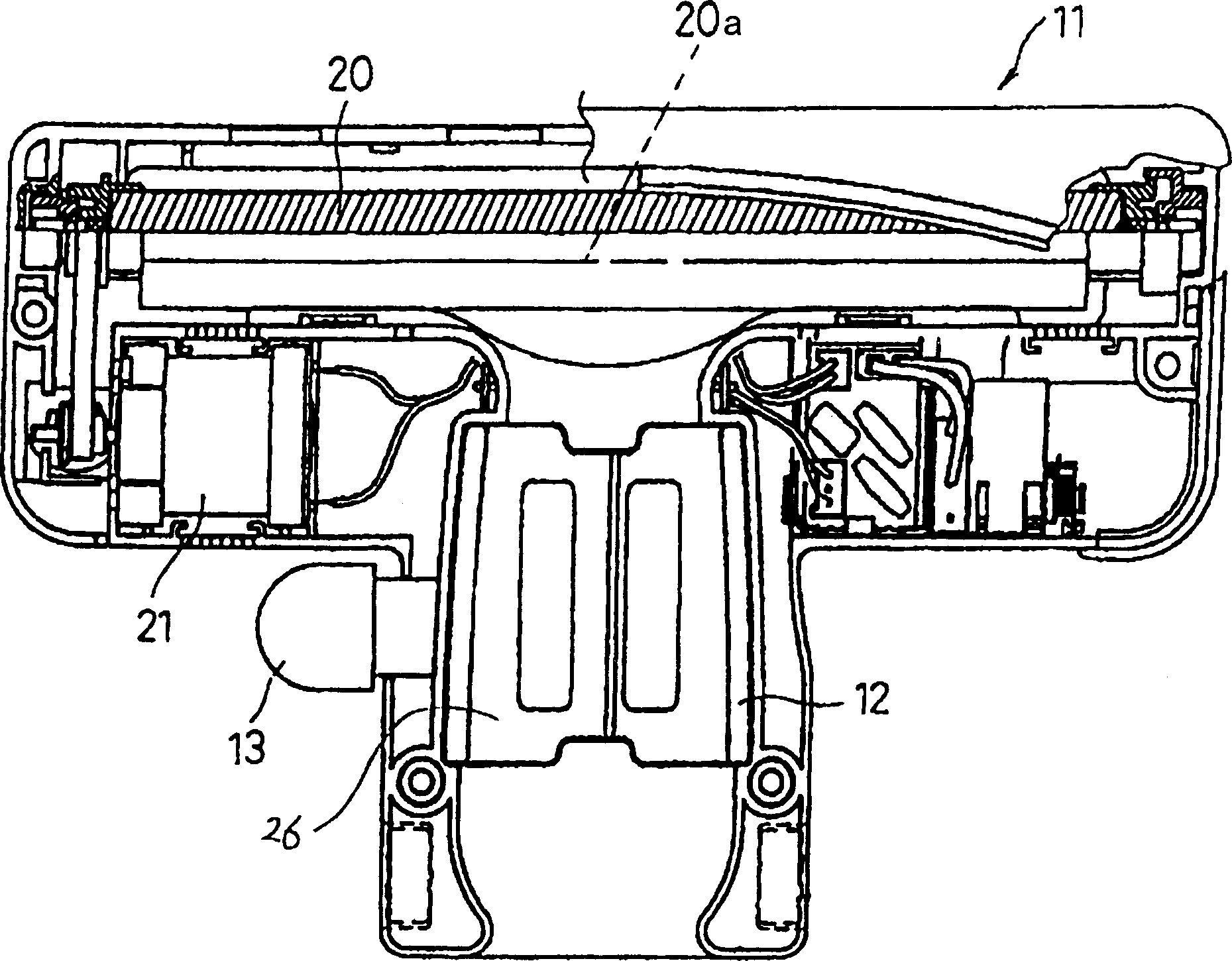

[0034] Above-mentioned suction head 3 such as figure 2 As shown in (a), (b), it consists of a floor suction head 11 and a small suction head 10 detachably mounted thereon. The small suction head 10 is provided with: a connecting pipe 9 constituting a connecting part for connecting with the extension pipe 2; The rotary coupling member (rota...

Embodiment 2

[0059] Next, use Figure 10 ~ Figure 11 The second embodiment of the present invention will be described. Here, the same constituent elements as those in the above embodiment are given the same symbols, and their descriptions are omitted.

[0060] The bottom surface of small suction head 10 is as Figure 10 It is made into an arc shape as shown in , and has a plurality of openings 23 . The brush group 27 that is arranged on a base cloth 36 is housed on the bottom apex position of arc direction, and this brush group 27 is as Figure 11 have a different charge sequence as shown in . Bottom surface openings 23 are provided on both sides of the brush group 27, and the brush groups 27 are also installed on their outer sides.

[0061] The operation in the above structure is as follows.

[0062] When cleaning, the brush group 27 rubs against the surface to be cleaned. At this time, the bristles 34 made of easily positively charged material and the bristles 35 made of easily negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com