Producing process for container body with seamless continuous extruding plastic wind

A production process and no welding seam technology, which is applied in the production of the container body and the production process of the container body, can solve the problems of large consumption of raw materials, complicated production process, waste of raw materials, etc., and achieve the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

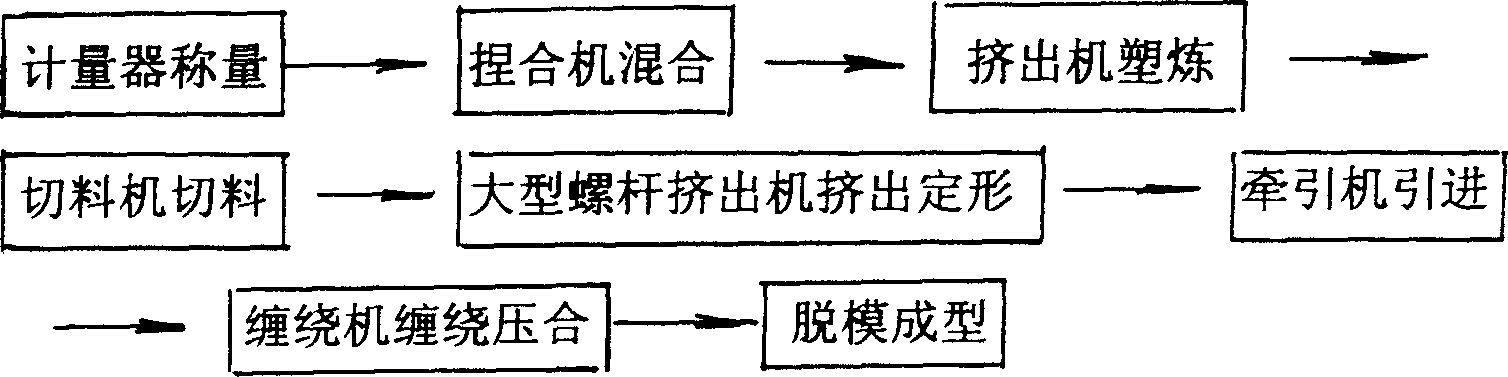

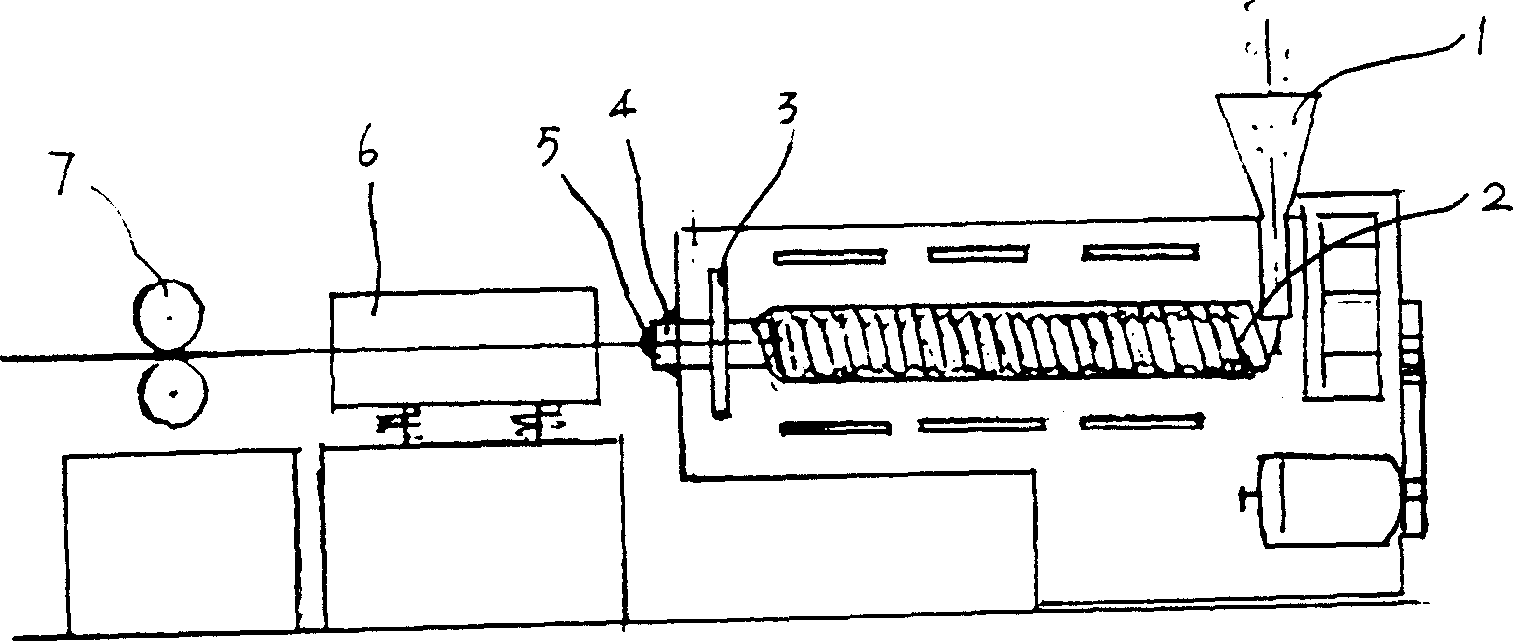

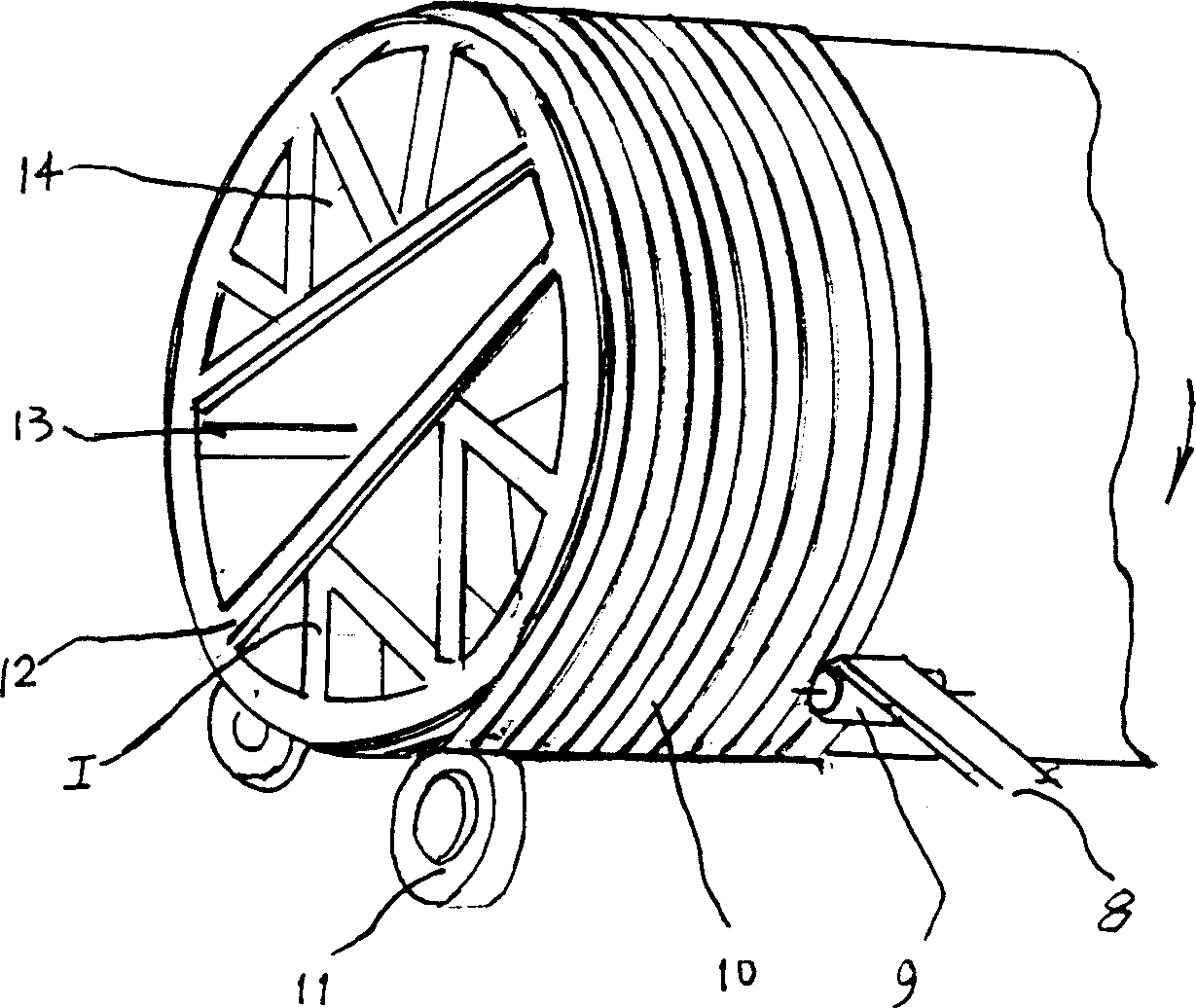

[0015] see figure 1 , The raw material formula is: 90% of isotactic polypropylene resin, 9.5% of filler glass fiber, 0.1% of coupling agent, and 0.4% of other additives. After weighing, put them into the kneader and mix them separately. Under the condition of 170℃, send the fully kneaded powder into the extruder for mastication. The diameter of the extruded product is 5-6 mm, and it is drawn to the The granulator cuts it into pellets with a length of about 8 mm to form pellets for use; the container body made of the pellets has high strength and can withstand a temperature of up to 120°C. It should be noted that carbon fiber can also be used as the glass fiber, and the coupling agent is used to increase the bonding force between materials; the rest of the additives can be selected to add colorants, anti-ultraviolet agents, antioxidants, and anti-oxidants according to the needs of the outer layer of the container body. Mold etc. When the container body contains flammable orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com