Water-proof shoes or boots and producing method thereof

A manufacturing method and technology for waterproof shoes, applied in footwear, clothing, applications, etc., can solve problems such as stuffy, uncomfortable, polluted water quality of waterproof shoes or boots, and achieve the effects of good anti-slip effect, light wearing and not easy to fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

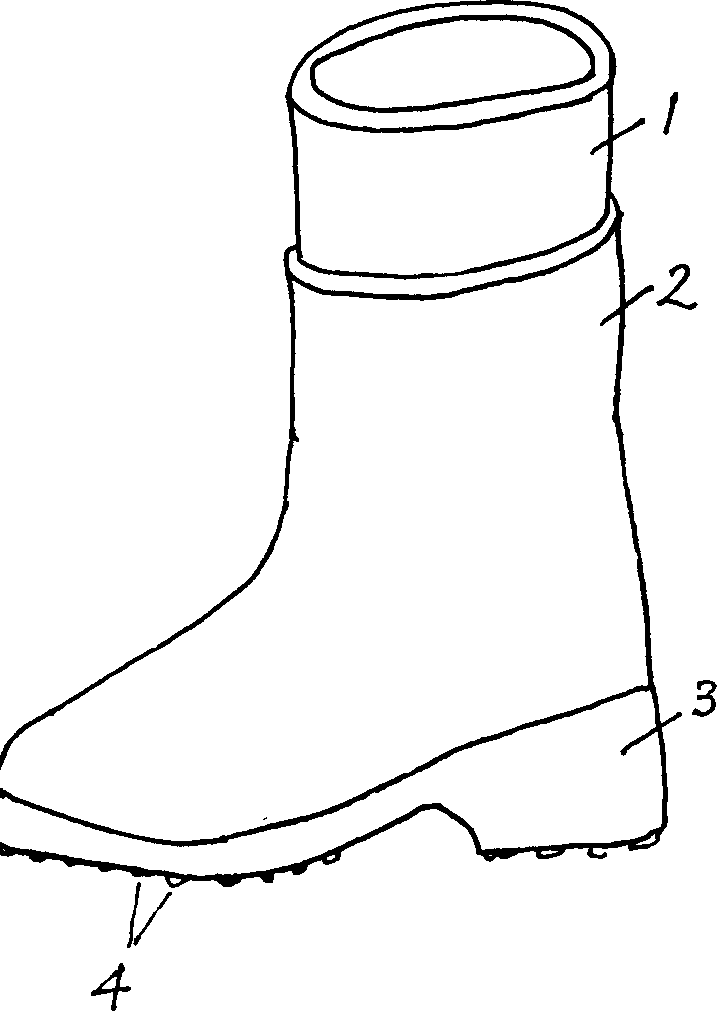

[0012] Embodiment 1. present embodiment waterproof shoes or boots, its structure can refer to figure 1 , it contains inner 1, shell surface 2 and outsole 3, is characterized in that: its shell surface and outsole are non-toxic, light polyurethane material. So that they do not pollute the environment and water quality during use, disposal or manufacture.

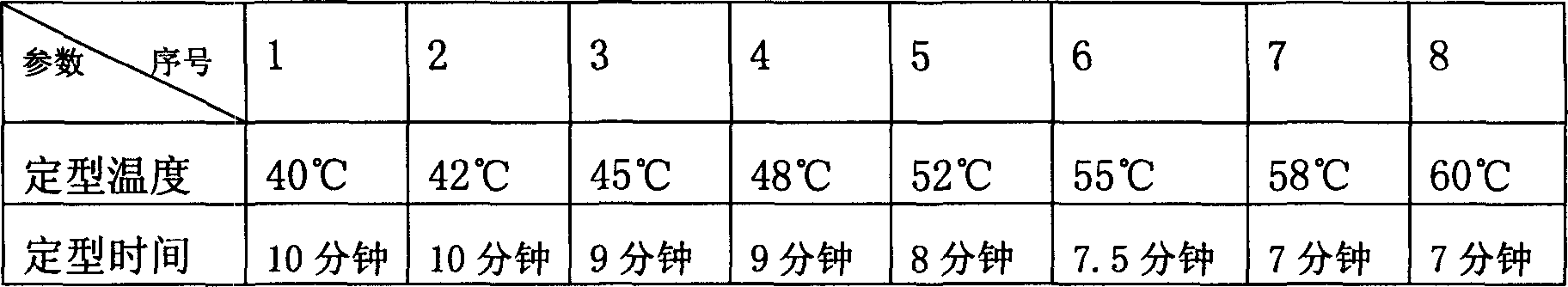

[0013] The manufacturing method of waterproof shoes or boots in this embodiment: 1) first select a last and a polyurethane outsole according to the size of the shoe or boot, and make an inner lining according to the shape and size of the last and put it on the last; 2) according to the shell Make a mold based on the shape and thickness of the surface and put it on the inside and outside of the last, and then put a polyurethane outsole on the bottom of the mold; 3) Take the polyurethane stock solution and pour it into it through the pouring machine In the cavity surrounded by the mold, the inner lining with the last and the o...

Embodiment 2

[0016] Embodiment 2. The structure of the present embodiment waterproof shoes or boots can also refer to figure 1 , It differs from Embodiment 1 in that: it consolidates hard scraps 4 on the bottom surface of the outsole 3. The hard debris can be a kind of particles that can still maintain its hardness on ice and snow and play an anti-slip effect, such as broken shells, etc.; A substance that hardens and has a hardness like steel, such as sensory rubber pellets.

[0017] The manufacturing method of the waterproof shoes or boots of this embodiment is different from that of Embodiment 1 in that the bottom of the mold also includes a cavity capable of pouring the outsole, and before pouring the polyurethane stock solution, the mold The bottom surface of the mold is placed with hard debris that can still maintain its hardness in ice and snow, such as broken shells, induction rubber particles, etc.

Embodiment 3

[0018] Embodiment 3. The difference between this embodiment and the waterproof shoes or boots of Embodiment 1 or 2 is: its inner material is neoprene foamed thermoplastic rubber, and the height of the inner lining 1 is higher than the height of the shell surface 2. To facilitate its connection with water pants such as water pants and fishing pants.

[0019] The manufacturing method of the waterproof shoes or boots of this embodiment is different from that of Embodiment 1 in that: the inner lining of neoprene foamed thermoplastic rubber needs to be made first and put on the last. The height of the top surface of its shaped membrane is lower than that of the inner lining, so that the height of the inner lining 1 is higher than that of the shell surface 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com