Burning system of spark plug ignition room

A technology of a combustion system and a spark plug, which is applied in the field of ignition type engines, can solve the problem that ignition type engines are difficult to ignite due to combustible gas mixture, and achieve the effects of saving fuel, reducing noise and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

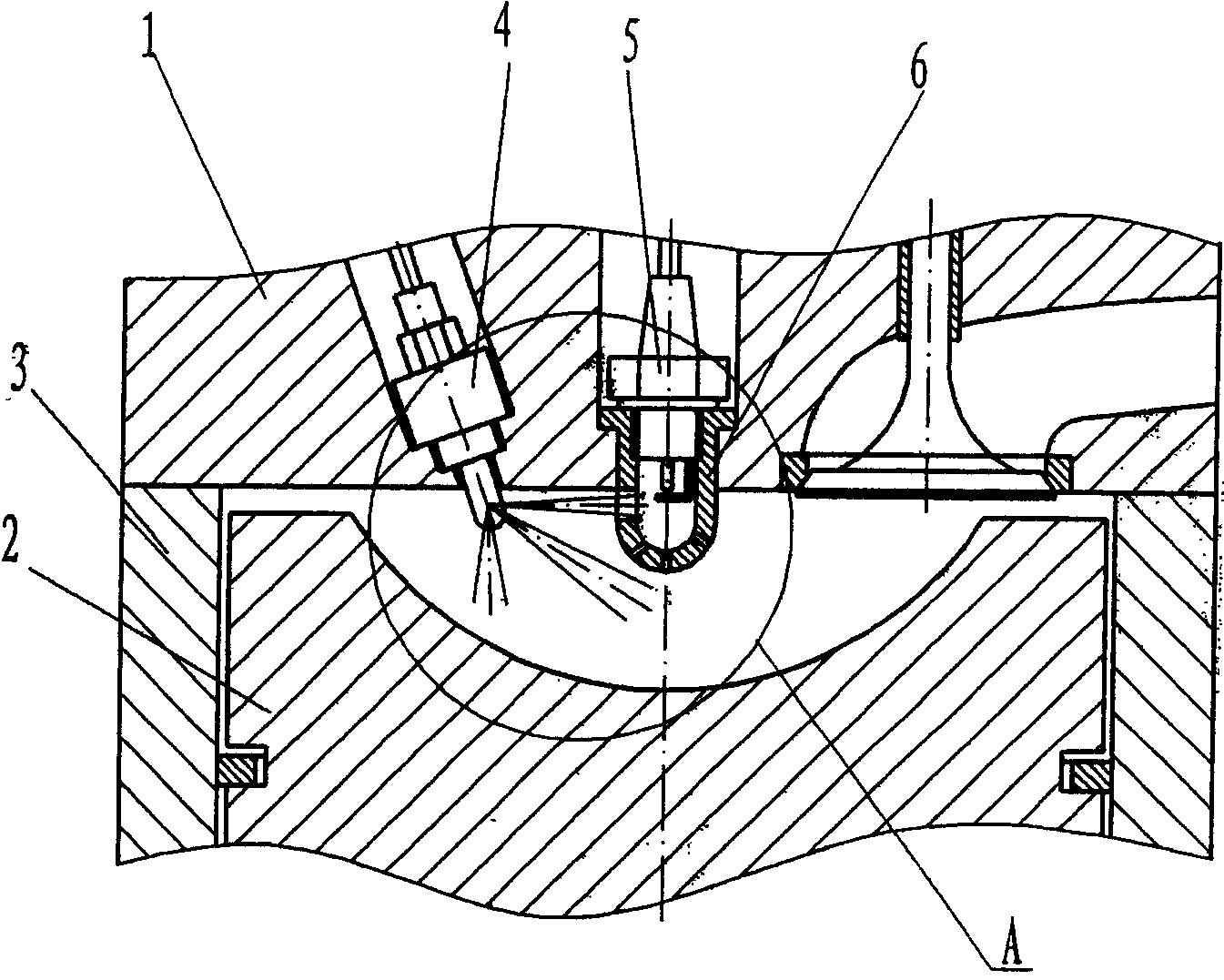

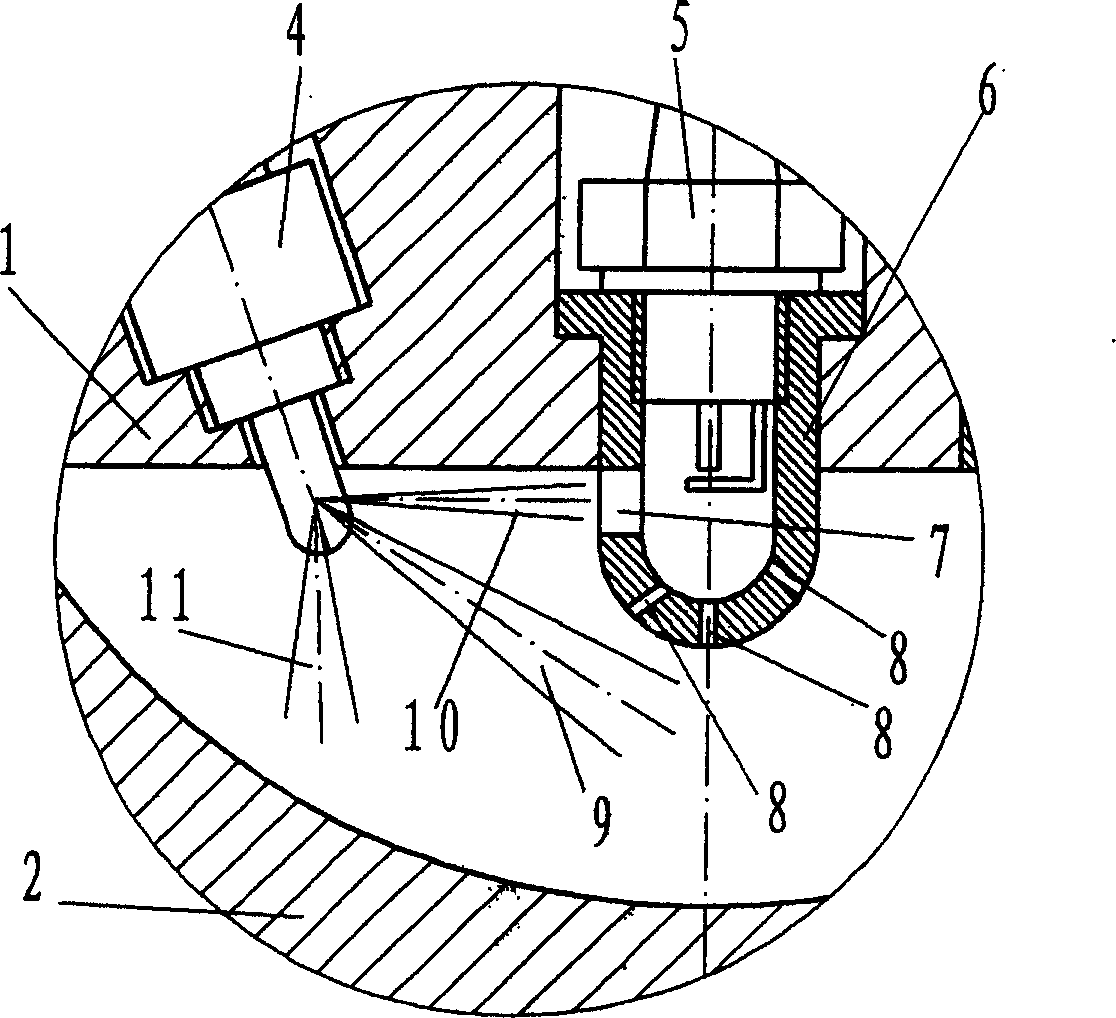

[0011] exist figure 1 , 2 In the shown embodiment, the combustion chamber of the engine is formed by the cylinder head (1), the piston (2) and the cylinder liner (3). The fuel injector (4) is obliquely installed in the cylinder head (1), and the ignition chamber (6) with the spark plug (5) is also installed in the cylinder head (1), and the ignition chamber (6) is fastened in the cylinder head (1) by interference fit. The upper and lower parts of the cylinder head (1) protrude from the lower plane of the cylinder head (1). The ignition chamber (6) is provided with a fuel inlet (7), and several nozzles (8) for combustible mixture combustion flames are provided in different directions on the lower wall. A fuel beam (10) of the fuel injector (4) is directly injected into the inner cavity of the ignition chamber (6) through the fuel inlet (7), so that a thicker combustible gas is formed around the electrode of the spark plug (5), which is very conducive to ignition. mixed gas. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com