Control method and control circuit of output light power and extinction ratio of light transmitter

A technology of optical transmitter and control method, which is applied in the direction of electrical components, transmission systems, electromagnetic wave transmission systems, etc., can solve the problems of injury to users, inability to solve individual differences in laser performance, low frequency response of backlight photocells, etc., and achieve extended The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

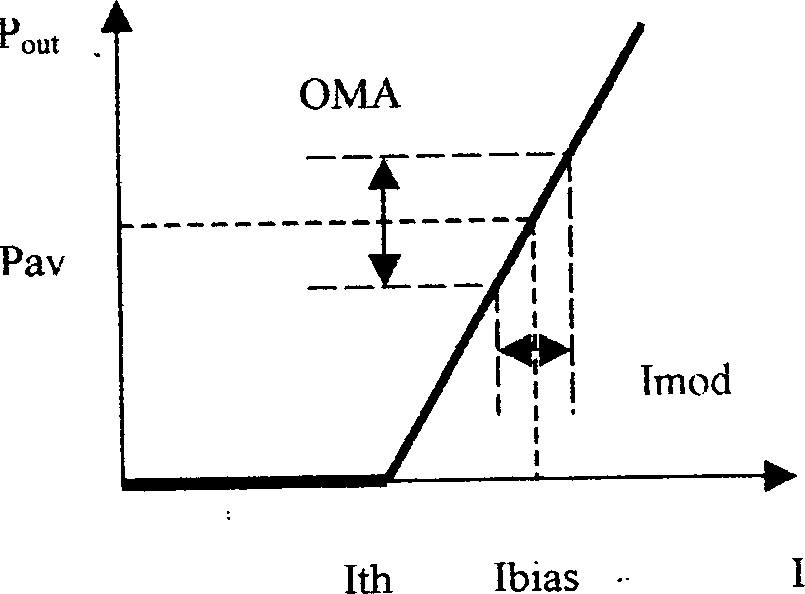

[0039] Example 1. A method for controlling output optical power and extinction ratio of an optical transmitter. It still uses the APC circuit for automatic control, monitors the change of the average luminous power through the backlight photocell, and adjusts the average output light power Pav by changing the Ibias bias current. It includes the following steps:

[0040] ①Set the average output optical power Pav, bias current Ibias, threshold Ith, and optical modulation amplitude OMA of the initial working point of the light source at room temperature 0 , Extinction ratio ER 0 And the modulation current Imod, calculate the slope SE of the curve at room temperature 0 =OMA / Imod;

[0041] ②Set the variable ranges of Pav, Ibias, Ith, OMA, ER, and Imod variables allowed by the optical transmitter to Pav±Δ 1 、Ibias±Δ 2 、Ith±Δ 3 、OMA±Δ 4 、ER±Δ 5 、Imod±Δ 6 ;

[0042] 3. Utilize the automatic optical power control circuit APC to control and keep Pav constant, and monitor Ibia...

Embodiment 2

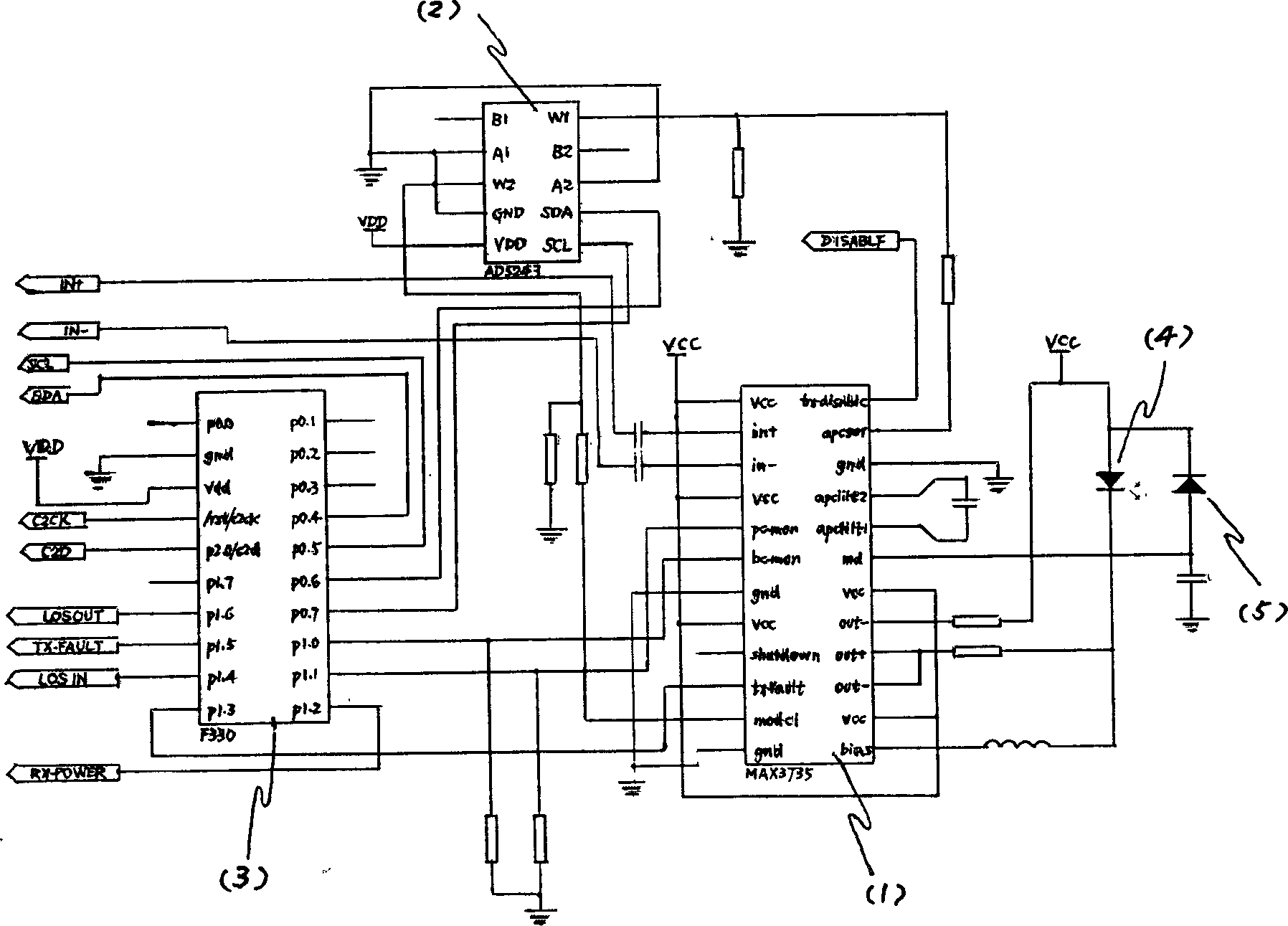

[0046] Example 2. A control circuit for output optical power and extinction ratio of an optical transmitter, as shown in FIG. 2 . It includes a driver (1), a digital potentiometer (2), a microprocessor (3), a laser (4), and a backlight photoelectric tube (5). The out-pin of the driver (1) is connected to Vcc and the positive pole of the laser (4) and the negative pole of the backlight photocell through a resistor, its bias pin is connected to the negative pole of the laser (4) through an inductance coil, and its md pin is connected to the backlight photocell ( 5) Positive connection. The driver (1), digital potentiometer (2) and microprocessor (3) are interconnected with each other.

[0047] The model of the driver (1) is MAX3735, the model of the digital potentiometer (2) is AD5243, and the model of the microprocessor (3) is F330.

[0048] Embodiment 1 and Embodiment 2 can automatically control the average output optical power and extinction ratio of the optical transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com