Hyperboloid-ellipsoid combined rear tool face twist drill

A flank and twist drill technology, applied in twist drills and other directions, can solve the problems of difficult grinding and high cost, achieve high drilling accuracy, reduce axial force, and reduce surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

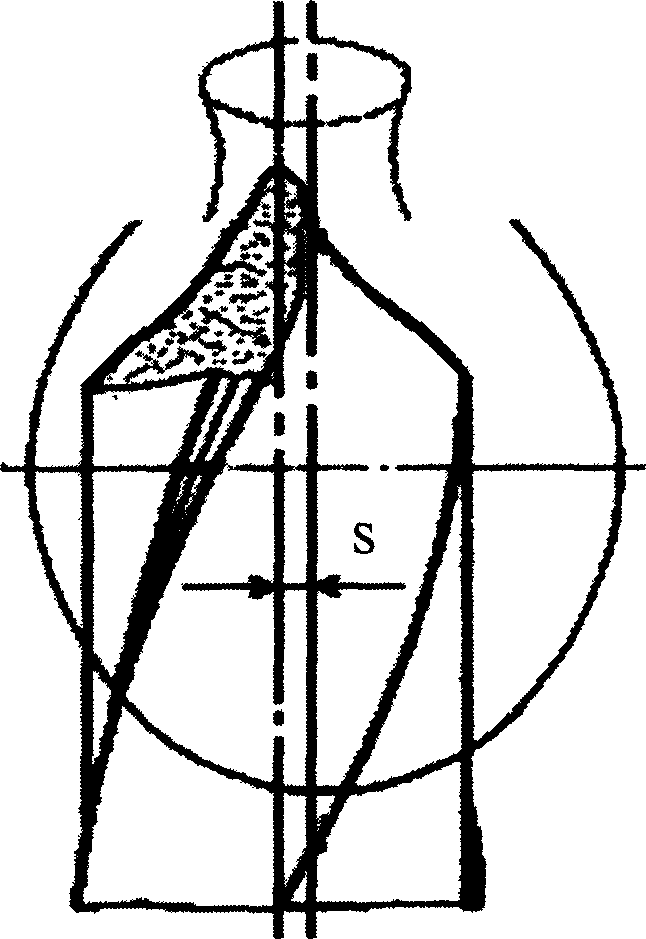

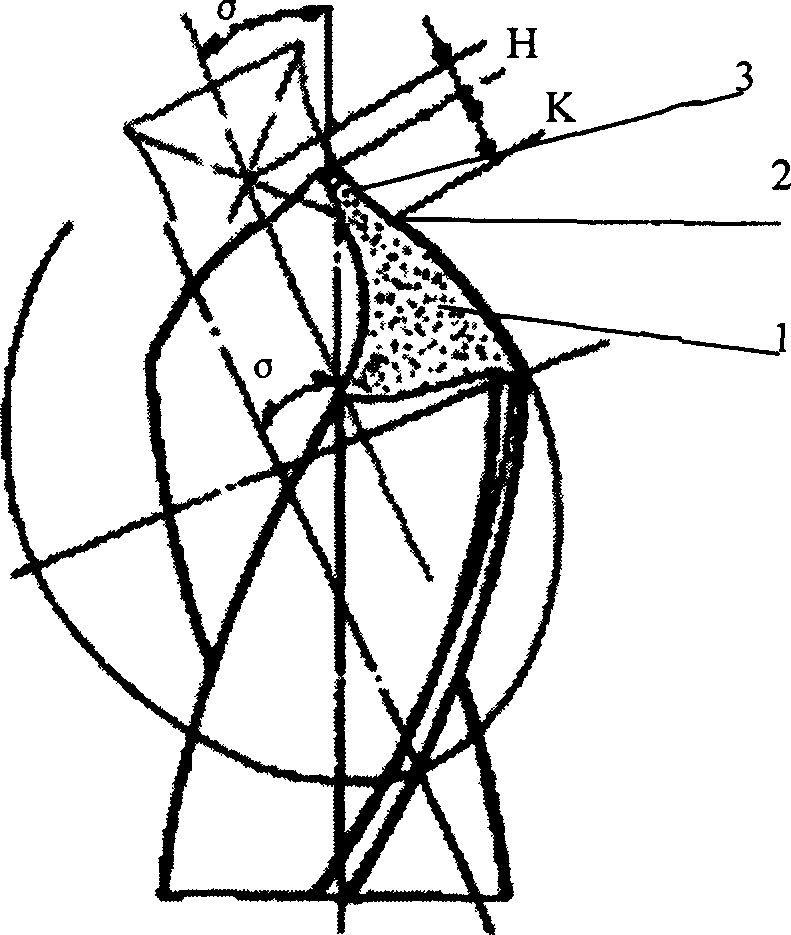

[0036] like figure 1 , figure 2 As shown, the flank of the twist drill is a hyperboloid-ellipsoid composite flank, that is, the part of the flank of the twist drill close to the drill core is a rotating single leaf hyperboloid 3, and the rest of the flank is an ellipsoid 1 . Molding parameters: hyperboloid: a=9, c=9, σ=32°, H=0.5, S=4; ellipsoid: A=19, C=43, σ=32°, S=4; hyperboloid drill Spike height K=4.

[0037] In this embodiment, the point grinding process (disclosed in Chinese invention patent 03132068.6) is adopted, and the point grinding CNC machining program is compiled according to the above parameters; the CNC point grinding forming process program is run, and the hyperboloid point grinding forming CNC machining program is firstly started from the core. Program, after reaching the specified height of the hyperboloid dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com