Production technology for extracting vanadium and molybdenum from spent aluminum base molybdenum catalyzer using wet method

A production process and catalyst technology, applied in the field of metallurgy, can solve problems such as waste of molybdenum resources, and achieve the effects of low production cost, simple process and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

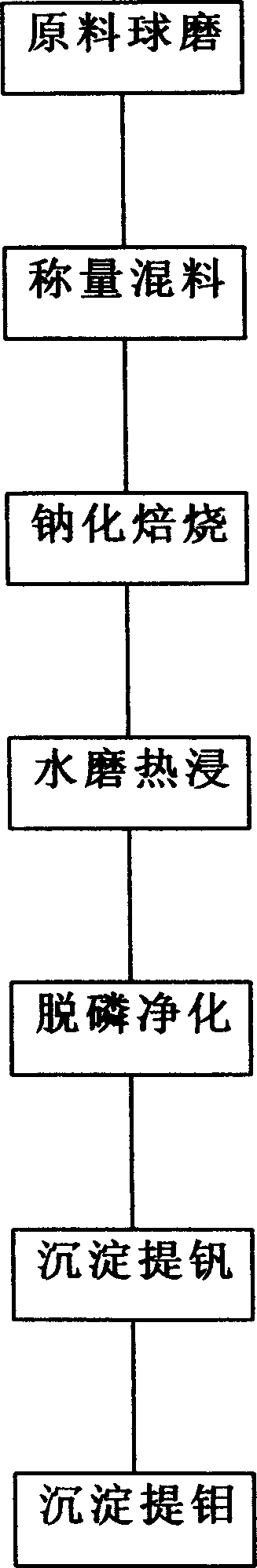

[0049] It proceeds in the following steps:

[0050] (1) Raw material ball milling: After the waste aluminum-based molybdenum catalyst material is subjected to surface deoiling treatment, it is sent into a ball mill to be ball-milled into powder, and the particle size of the waste aluminum-based molybdenum catalyst powder is controlled to be 80 mesh;

[0051] (2) Weighing and mixing: according to the specified ratio of raw materials (by weight):

[0052] Waste aluminum-based molybdenum catalyst (converted to contain V 2 o 5 measure) 1 part,

[0053] Soda ash (Na 2 CO 3 ) 0.4 parts,

[0054] Glauber's salt (Na 2 SO 4 ) 0.4 parts,

[0055] Industrial salt (NaCl) 0.4 parts,

[0056] Measure and weigh the materials separately and send them into the screw mixer to mix them into mixed materials;

[0057] (3) Sodium roasting: the mixed material is sent into the rotary kiln by the disc feeder for sodium roasting reaction, the roasting temperature is controlled at 1000°C, and ...

Embodiment 2

[0085] It proceeds in the following steps:

[0086] (1) Raw material ball milling: After the waste aluminum-based molybdenum catalyst material is subjected to surface deoiling treatment, it is sent into a ball mill to be ball-milled into powder, and the particle size of the waste aluminum-based molybdenum catalyst powder is controlled to be 120 mesh;

[0087] (2) Weighing and mixing: according to the specified ratio of raw materials (by weight):

[0088] Waste aluminum-based molybdenum catalyst (converted to contain V 2 o 5 measure) 1 part,

[0089] Soda ash (Na 2 CO 3 ) 0.65 parts,

[0090] Glauber's salt (Na 2 SO 4 ) 0.65 parts,

[0091] Industrial salt (NaCl) 0.65 part,

[0092] Measure and weigh the materials separately and send them into the screw mixer to mix them into mixed materials;

[0093] (3) Sodium roasting: the mixed material is sent into the rotary kiln by the disc feeder for sodium roasting reaction, the roasting temperature is controlled at 1050°C, a...

Embodiment 3

[0121] It proceeds in the following steps:

[0122] (1) Raw material ball milling: After the waste aluminum-based molybdenum catalyst material is subjected to surface deoiling treatment, it is sent into a ball mill to be ball-milled into powder, and the particle size of the waste aluminum-based molybdenum catalyst powder is controlled to be 40 mesh;

[0123] (2) Weighing and mixing: according to the specified ratio of raw materials (by weight):

[0124] Waste aluminum-based molybdenum catalyst (converted to contain V 2 o 5 measure) 1 part,

[0125] Glauber's salt (Na 2 SO 4 ) 0.85 parts,

[0126] Measure and weigh the materials separately and send them into the screw mixer to mix them into mixed materials;

[0127] (3) Sodium roasting: the mixed material is sent into the rotary kiln by the disc feeder for sodium roasting reaction, the roasting temperature is controlled at 950°C, and the roasting time is 2 hours.

[0128] The following oxidation-sodium roasting reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com