Grease Composition For Use In Constant Velocity Joints

a constant velocity joint and grease technology, applied in the direction of lubricant compositions, additives, thickeners, etc., can solve the problems of wear on the contact surface, failure of the joints, fatigue of the rolling contact surface, etc., and achieve low friction, good compatibility, and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

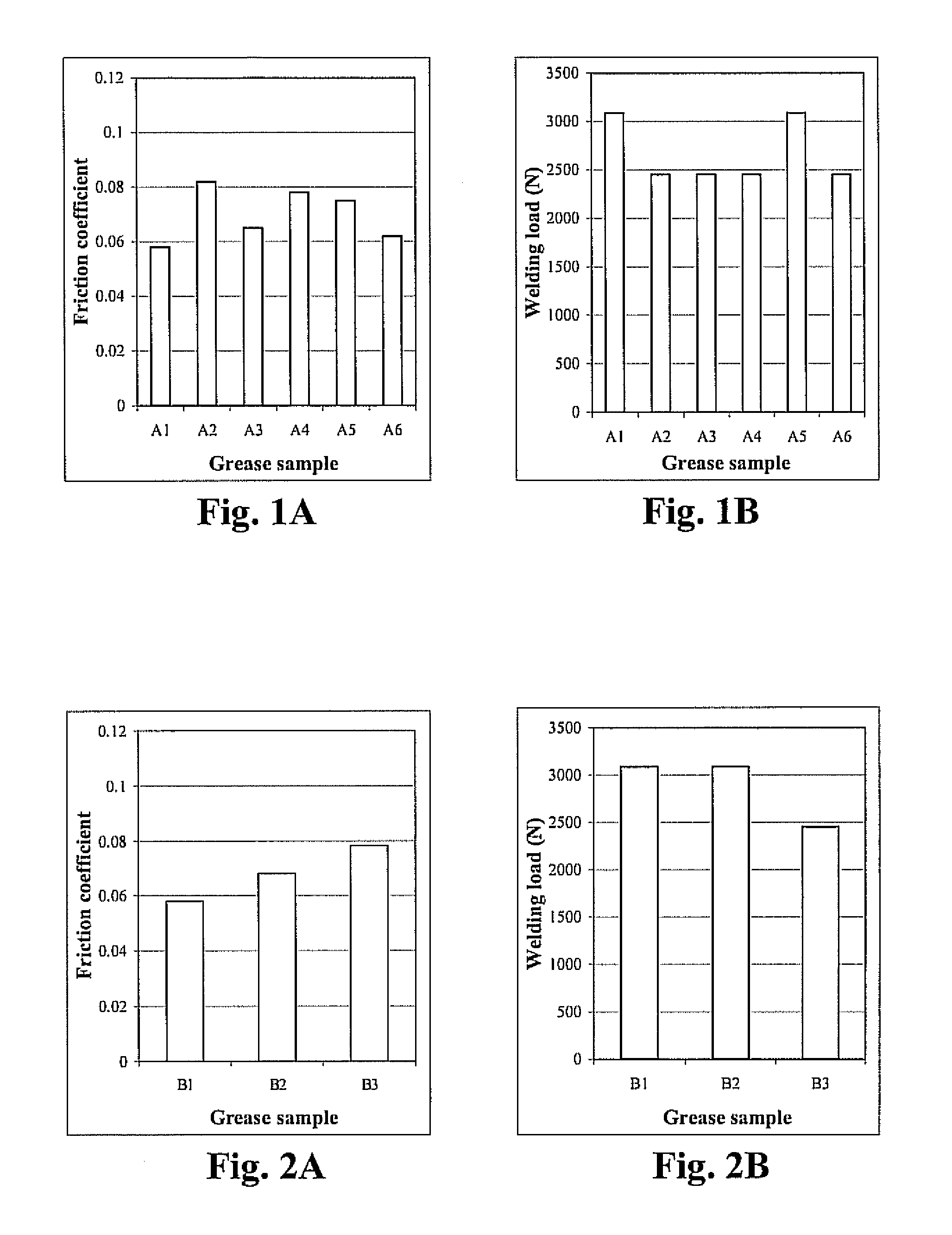

example b1 (

[0066]Example B1 (=A1) shows the lowest friction coefficient and highest welding load, and, thus, exhibits a very good extreme pressure performance when compared to examples B2 and B3. Further, the lowering of the amount of the TNMoS compound as well as the components of the additive package at values around 0.1% by weight clearly results in an increase of the friction coefficient and a decrease in the welding load. Thus, at least about 0.25% by weight of the TNMoS compound as well as at lest one of ZnDTPs, MoDTPs and MoDTCs should preferably be present in the grease composition.

[0067]In a third test series, the effect of the addition of a calcium complex thickener added to four grease compositions C1 to C4 in accordance with Table 3 is studied.

TABLE 3Grease CompositionExampleExampleExampleExample[wt %]C1 = A1C2 = A2C3C4TNMoS0.50.50.50.5ZnDTP0.50.50.50.5MoDTP0.50.50.50.5MoDTC0.50.50.50.5Calcium complex3.01.515thickeneroil blend879088.575Thickener8888

[0068]Example C2 is identical to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sliding friction coefficient | aaaaa | aaaaa |

| sliding friction coefficient | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com