Compound thermal insulation brick and production technology thereof

A composite thermal insulation and production process technology, applied in thermal insulation, manufacturing tools, structural elements, etc., can solve the problems of increasing the labor intensity of construction workers, poor thermal insulation effect, and increasing construction costs, and achieves the benefits of implementation, good thermal insulation performance, and economical savings. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

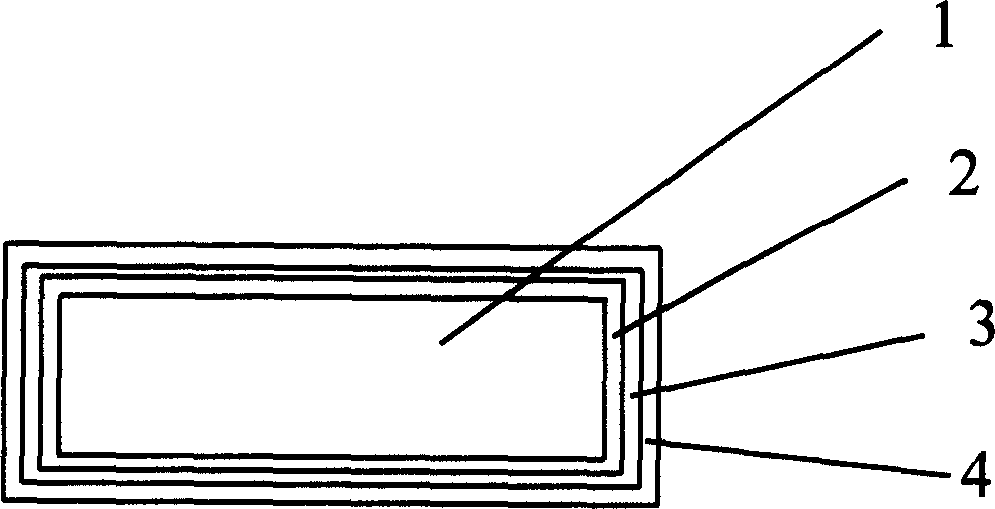

[0015] The composite thermal insulation brick of the present invention is made up of following structure: the inner layer is polystyrene foam block 1, the outer layer of polystyrene foam block 1 is cement and glue mixed layer 2, and the outer layer of cement and glue mixed layer 2 is reinforced Net 3, the outer layer of reinforced net 3 is cement layer 4.

[0016] In order to increase the strength and hardness of the insulating brick, a second cement layer 5 and a second reinforcing net 6 may be provided between the reinforcing net 3 and the cement layer 4 of the insulating brick.

[0017] The production technology of composite thermal insulation brick of the present invention is divided into following steps:

[0018] a: Cut the polystyrene foam board into pieces according to the length, width and height specifications of general insulation bricks.

[0019] b: Take ordinary cement and glue and mix evenly according to the weight ratio of 1:1; the glue can be three-round adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com