Method for preparing instant rice

A technology of instant rice and rice, which is applied in food preparation, food shaping, food science, etc., can solve the problems of lack of viscoelasticity, serious nutritional loss, and environmental pollution in soluble component instant rice, achieve excellent rehydration performance, and improve production Efficiency, the effect of shortening the cooking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

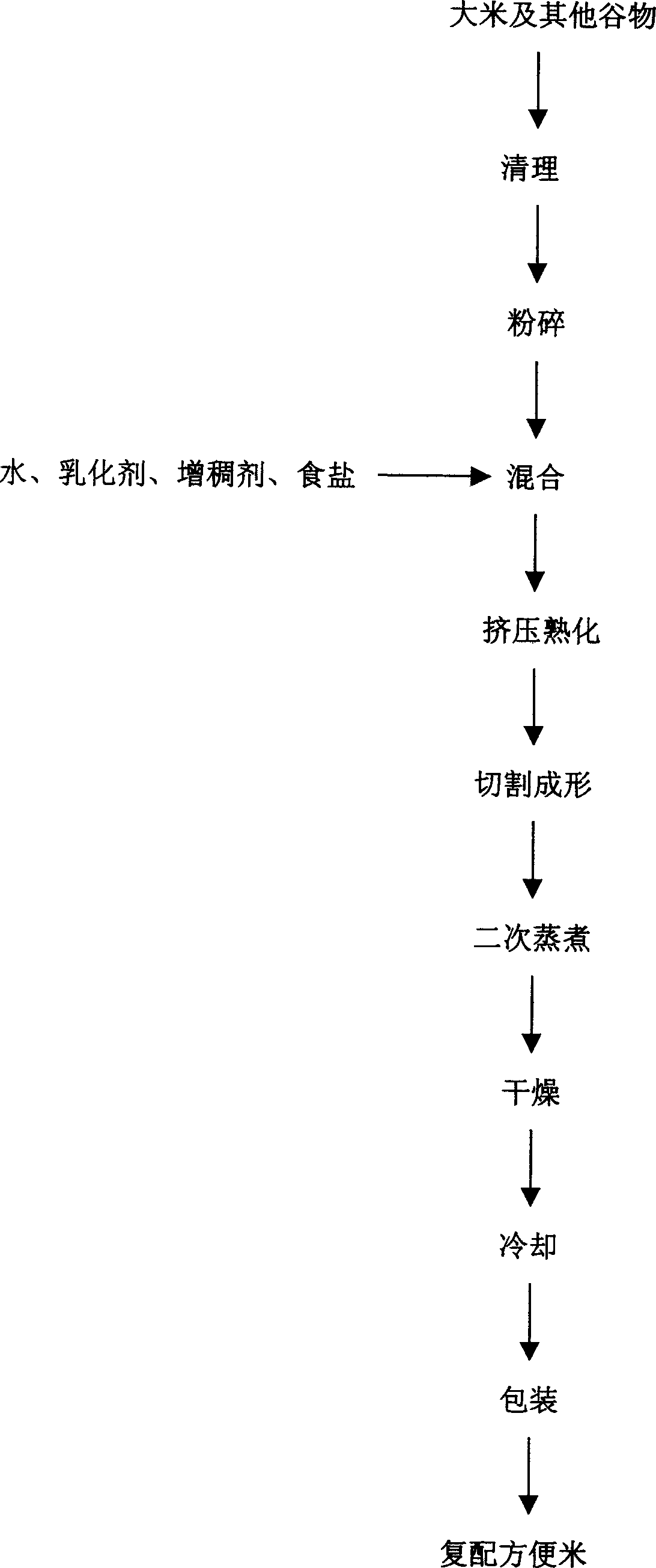

Method used

Image

Examples

Embodiment 1

[0026] The formula used: rice 87%, flour 10%, salt 2%, sodium alginate 0.5%, monoglyceride 0.5%. Processing conditions: Grind to particle size ≤ 250 microns, then add 32% water, mix for 3 minutes, extrude and mature, cut and shape, cook for 5 minutes, first dry at 120°C for 10 minutes, then dry at 95°C for 20 minutes, cool, Package.

[0027] The main indexes of the obtained product are as follows: the degree of gelatinization of the product is 91.5%, and the water content is 7.8%. After the product is soaked in hot water at 90 DEG C and sealed for 5 minutes, the delicious instant rice can be obtained.

Embodiment 2

[0029] The formula used: rice 85%, flour 10%, soybean protein powder 1%, gluten 1%, lecithin 0.5%, maltodextrin 0.5%, salt 2%. Processing condition is with embodiment 1, and gained product index is close with embodiment 1.

Embodiment 3

[0031] The formula used: 85% rice, 10% flour, 2% soybean protein powder, 0.5% sodium stearoyl lactylate, 0.5% gum arabic, and 2% table salt. Processing condition is with embodiment 1, and gained product index is close with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com