Method for preparing supper clean, and high pure reagent of acid and rectifier unit

A reagent and net height technology, applied in fractionation, chlorine/hydrogen chloride purification, sulfur trioxide/sulfuric acid, etc., can solve the problem of small occupied space, and achieve the effect of small occupied space, strong matching, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

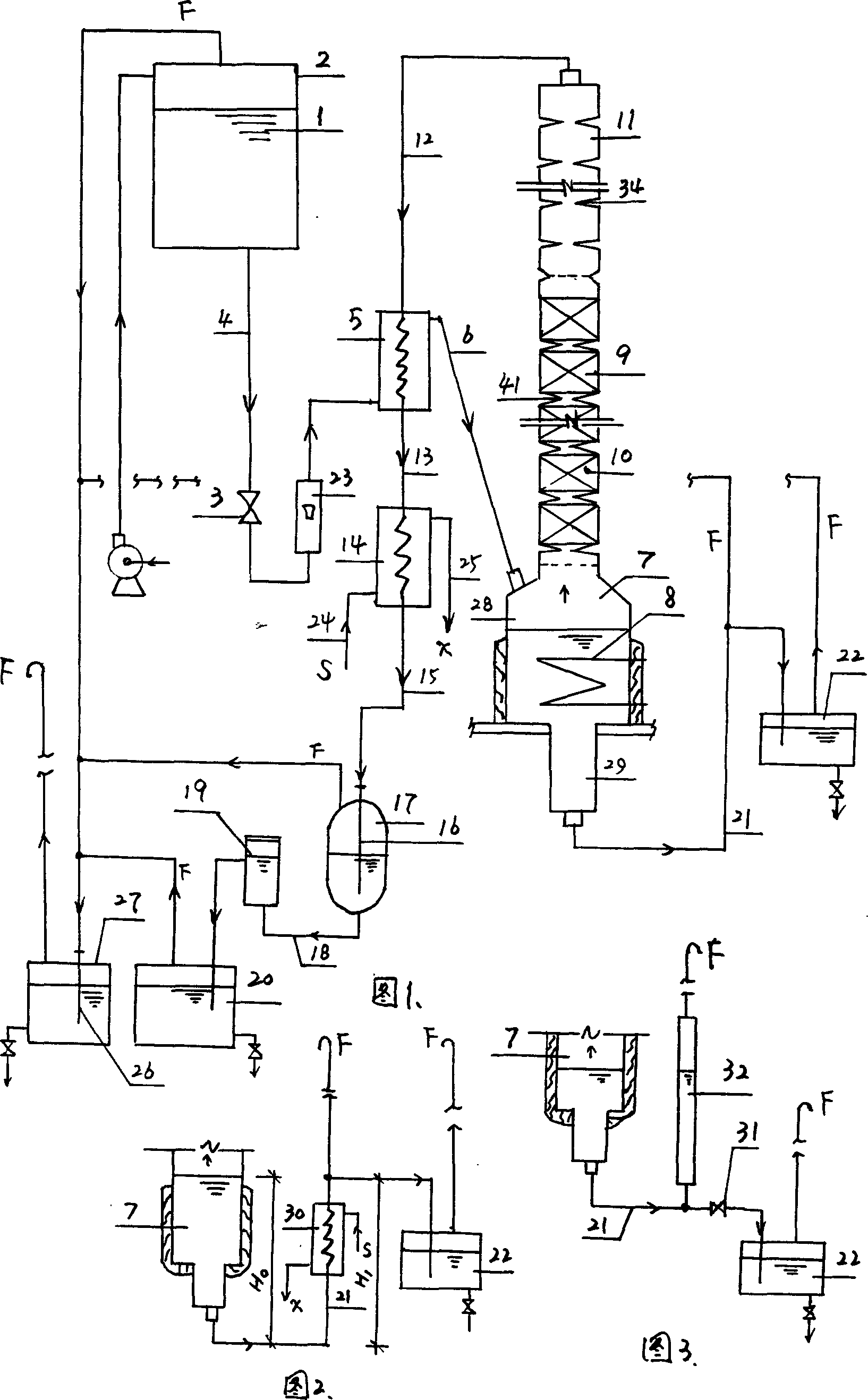

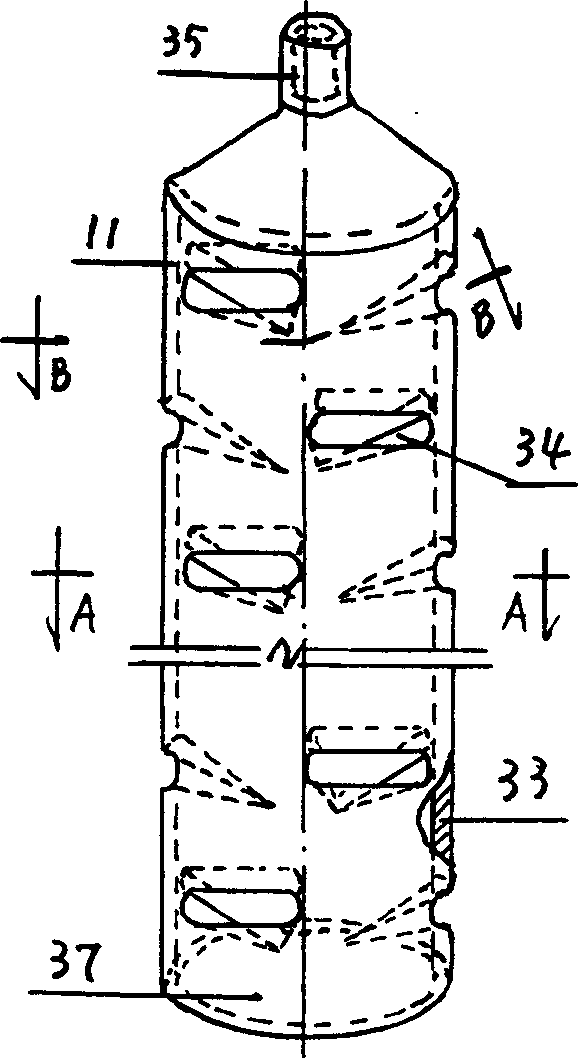

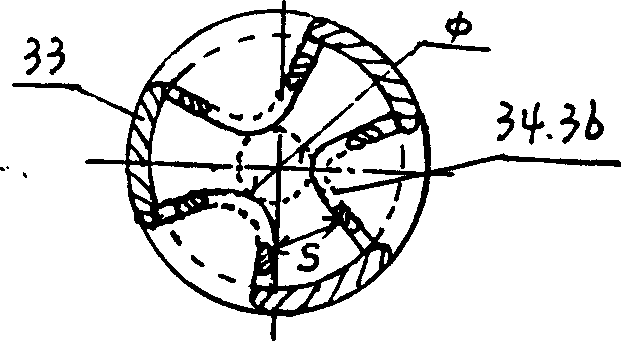

[0029] Further explain in detail in conjunction with accompanying drawings;

[0030] As shown in Figure 1, the raw material liquid 1 is preheated by the overhead distillate of the stab distillation tower 11 through the preheater 5, and then continuously enters the still 7, is heated to boiling by the coil heater 8, evaporates, and the steam rises and enters the packing successively. The tower 9 and the stab distillation tower 11 directly connected in series, the steam repeatedly undergoes partial condensation, partial vaporization reflux in the tower, and repeated close contact between the gas and liquid phases to perform mass exchange between the two phases, thereby achieving The purpose of separating the final product in the middle, and discharge the distillate from the top of the decapitation column 11 in a gaseous state, the distillate enters the condenser 14 after the preheater 5, and is condensed into a liquid product after being indirectly cooled by water, and then furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com