Treatment method of reducing hydrogen loss of optical fiber and devices in use for the method

A technology of processing equipment and processing method, which is applied in the field of reducing optical fiber hydrogen loss and the equipment used in the institute, can solve the problems of reducing wire tension, exceeding, and increasing additional loss, etc., and achieves low manufacturing cost, compact structure, and land occupation. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

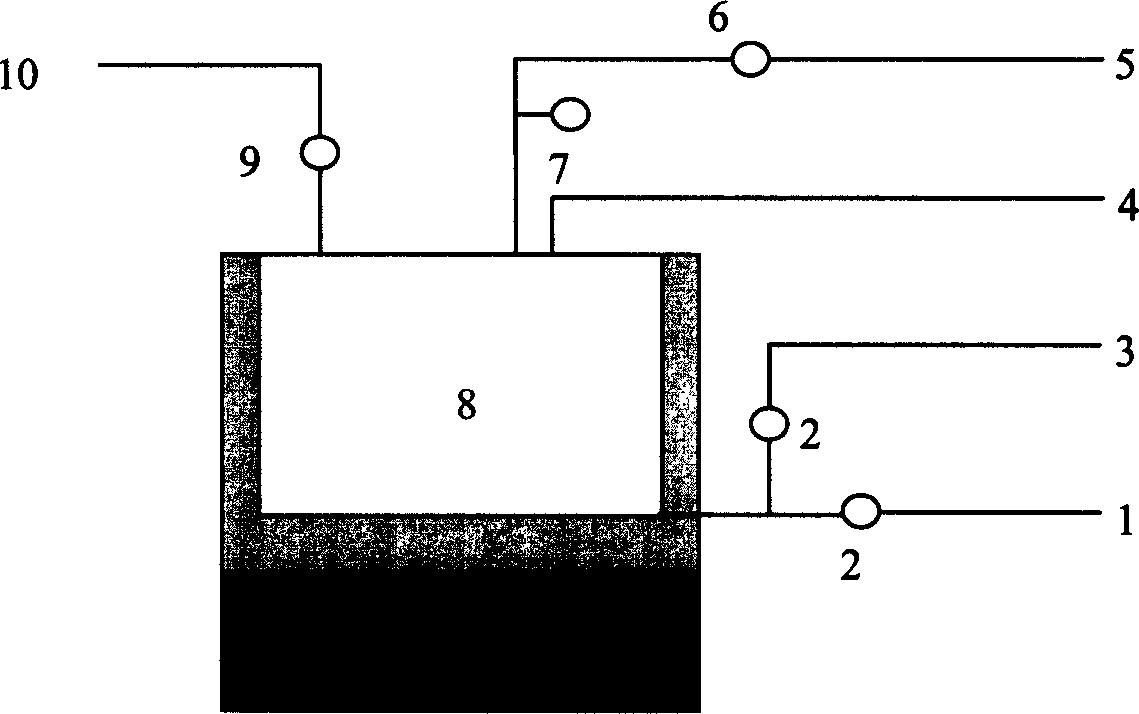

[0035] Put the drawn optical fiber into the figure 1 In the shown optical fiber deuterium processing chamber 8, the pure inert gas purging equipment is passed through the inert gas inlet 3 for 15 minutes, and then the temperature in the optical fiber deuterium processing chamber is heated to 25 to 50°C, and the optimum temperature is 40°C. Subsequently, the processing chamber is evacuated, and a mixed gas of deuterium and nitrogen is introduced into the deuterium processing chamber from the deuterium gas inlet 1, wherein the concentration of deuterium is 0.5% to 3%, and the optimum deuterium concentration is 2%. Optical fiber deuterium processing The pressure of the mixed gas in the chamber is 1.01×10 5 Pa to 2.02×10 5 Pa, the optimum pressure is 1.15×10 5 Pa, maintain this state for 10 to 30 hours, and the optimal time is 20 hours, then feed the inert gas by the inert gas inlet 3 and cool the temperature in the deuterium treatment chamber to room temperature, then the gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| additional attenuation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com