Method for producing low water peak single mode fiber with high efficiency

A single-mode optical fiber and low water peak technology, applied in the field of optical fiber, can solve problems such as potential safety hazards, and achieve the effects of improving processing effect, increasing diffusion rate, and good hydrogen aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

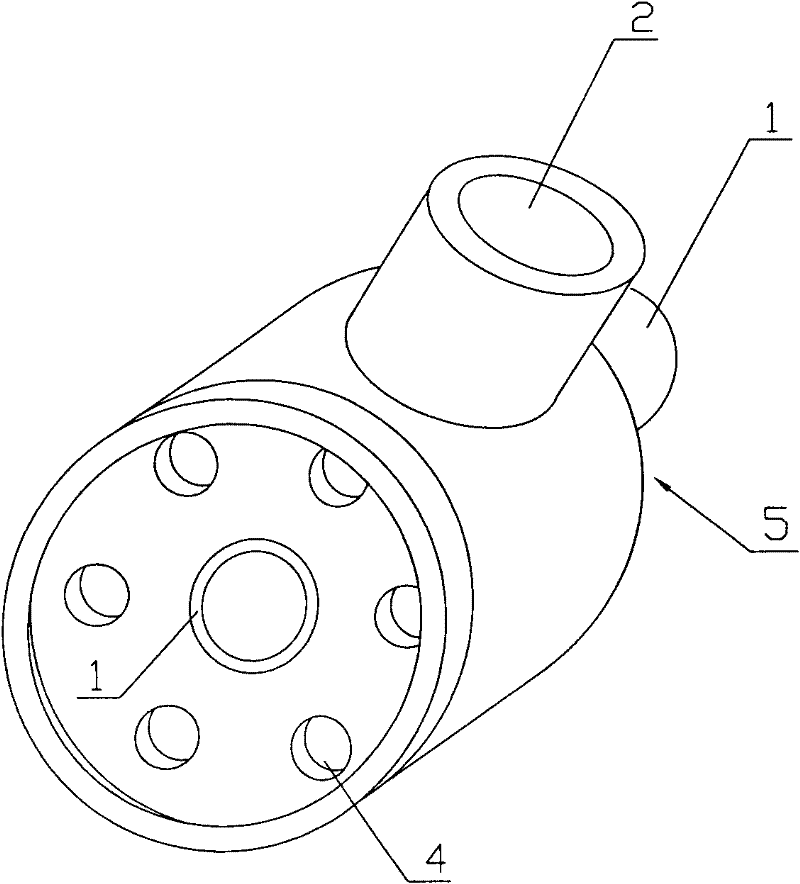

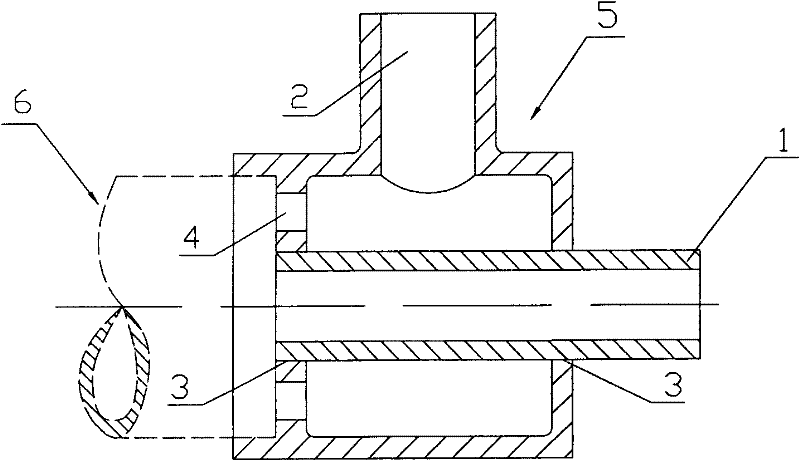

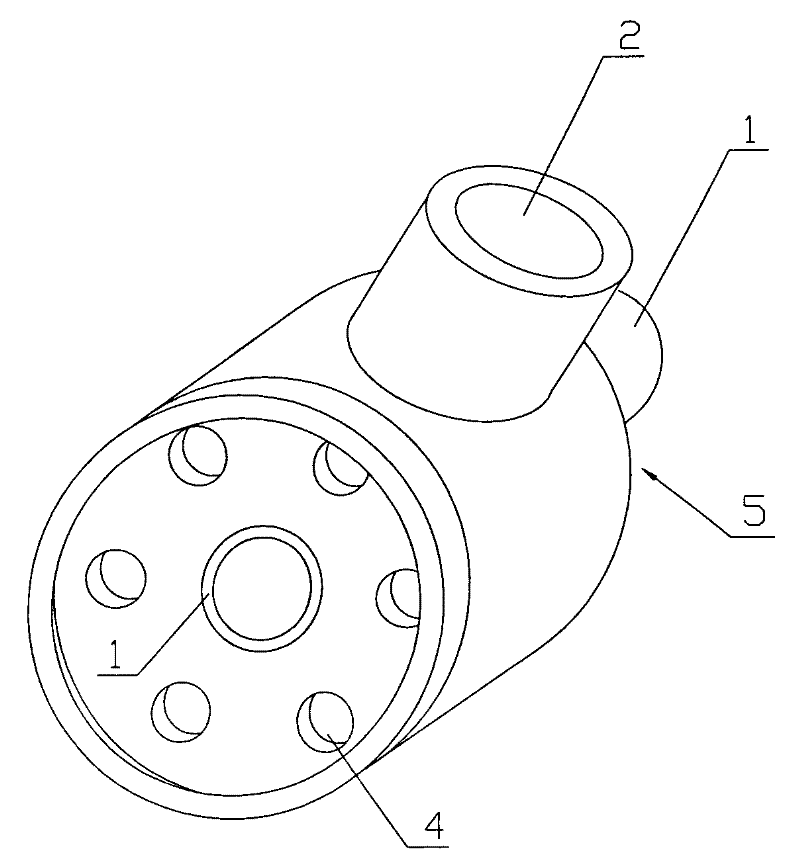

[0023] The speed during the preform drawing process is controlled at 800-1200m / min, preferably 1000m / min, so that the diameter of the optical fiber drawn from the preform is kept at 124-126 microns, preferably 125 microns. Then the first resin coating is performed, and after the first coating, the diameter of the optical fiber is maintained at 192-198 microns, preferably 195 microns. After coating, enter the UV light box for the first light curing. At this time, adjust the UV lamp control cabinet to keep the light intensity of the UV lamp at 100-150mW / cm 2 , preferably 120mW / cm 2 . The temperature is kept at 200-300°C, the light emitted by the UV lamp is reflected into the quartz tube container through the reflector, and the internal temperature should be kept at 150-200°C. The mixed gas whose deuterium concentration is 1-2% and the rest is nitrogen enters the quartz tube 6 evenly and continuously from the six air holes 4 of the intake element at one end of the quartz tube ...

Embodiment 2

[0025] The speed during the preform drawing process is controlled at 800-1200m / min, preferably 1000m / min, so that the diameter of the optical fiber drawn from the preform is kept at 124-126 microns, preferably 125 microns. Then the first resin coating is performed, and after the first coating, the diameter of the optical fiber is maintained at 192-198 microns, preferably 195 microns. After coating, enter the UV light box for the first light curing. At this time, adjust the UV lamp control cabinet to keep the light intensity of the UV lamp at 100-150mW / cm 2 , preferably 120mW / cm 2. The temperature is kept at 200-300°C, the light emitted by the UV lamp is reflected into the quartz tube through the reflection plate, and the internal temperature should be kept at 150-200°C. The mixed gas whose deuterium concentration is 1-2% and the rest is argon enters the quartz tube 6 evenly and continuously from the six air holes 4 of the intake element at one end of the quartz tube 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com