Temperature-resistant hydrogenated wiredrawing tower grating array and preparation method thereof

A technology of grating array and drawing tower, which is applied in the direction of grating fiber, optics, light guide, etc., can solve the problems of reflectivity attenuation, increase of optical fiber transmission loss, and restoration of optical fiber loss to the previous level, so as to reduce signal attenuation and maintain Effect of temperature resistance and improvement of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

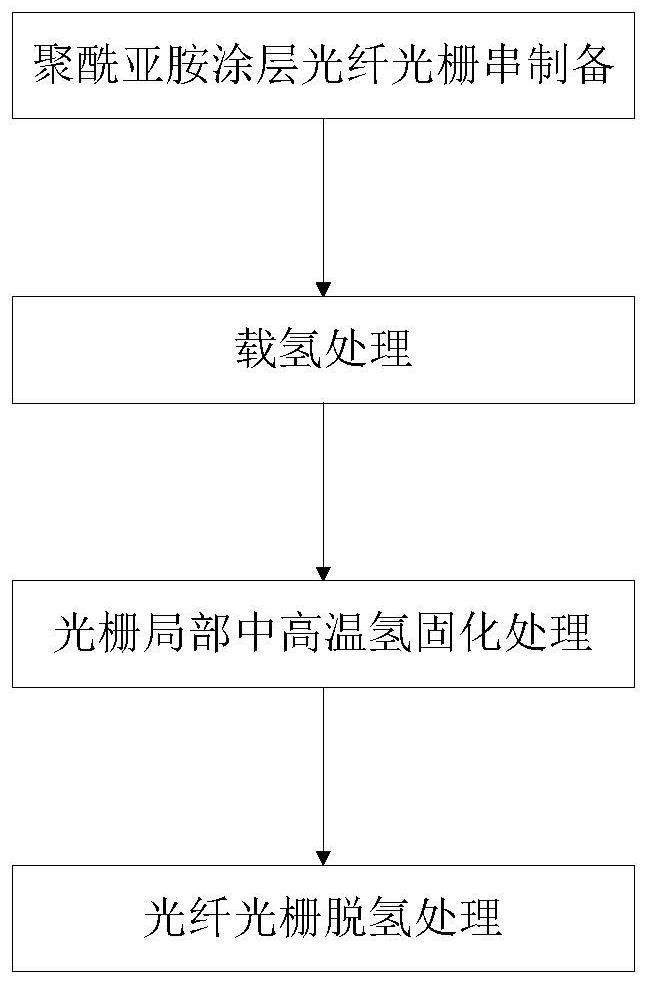

[0030] like figure 1 As shown, the method for preparing a temperature-resistant hydrogenated drawing tower grating array of the present invention includes the following steps:

[0031] A polyimide-coated seed grating array fiber is prepared by a drawing tower;

[0032] High-pressure hydrogen loading treatment on the polyimide-coated seed grating array fiber;

[0033] The array grating of hydrogenated fiber is subjected to hydrogen curing treatment at 300℃;

[0034] The whole length of optical fiber after hydrogen curing treatment is dehydrogenated at a temperature of 100°C to obtain a high temperature resistant grating array sensing fiber.

[0035] Further, the pressure during the hydrogen-carrying treatment is 10 MPa, and the hydrogen-carrying time is about 1 week.

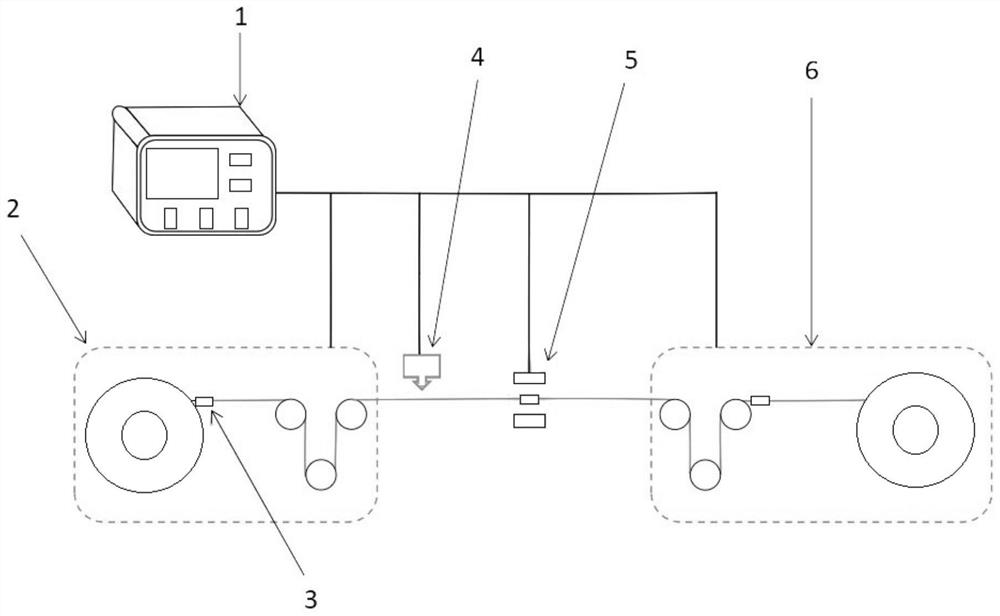

[0036] Further, the 300° C. high-temperature hydrogen curing treatment is carried out in an optical fiber receiving and unwinding system with a temperature-controlled tubular furnace, and the treatment time is...

Embodiment 1

[0041] Step 1: Preparation of polyimide-coated fiber grating strings.

[0042] The method for preparing the optical fiber grating of the present invention is as follows: the quartz glass matrix optical fiber preform is clamped on the optical fiber drawing tower to be melted and drawn, and the melted bare optical fiber is continuously extended downward, firstly, the grating is written, and then the outer layer is coated with the outer layer. and curing to obtain a polyimide-coated fiber grating string, which is finally received in a take-up reel. The coating is polyimide glue, the viscosity at room temperature is 13000~15000mPa.s, the molecular weight is between 50000~60000, and the coating thickness is 4~10 microns; curing conditions: primary curing 120~180℃, secondary and tertiary curing 250℃~350℃.

[0043] In step 1, the optical fiber preform is placed in a wire drawing furnace, and the lower end of the preform is melted and then taped to form a wire. The diameter of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com