Tool type barrel templates and tailgate platform

A tool-type, barrel mold technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as collision with the well wall, difficult adjustment, and difficult to follow the platform in place accurately, etc. To achieve the effect of making up for high and low errors and reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1: The present invention consists of two parts, a tool-type cylinder mold and a matching follow-up platform.

[0062] 1. Tool cylinder mold:

[0063] The tool-type barrel mold is connected as a whole by the barrel mold and the formwork support frame:

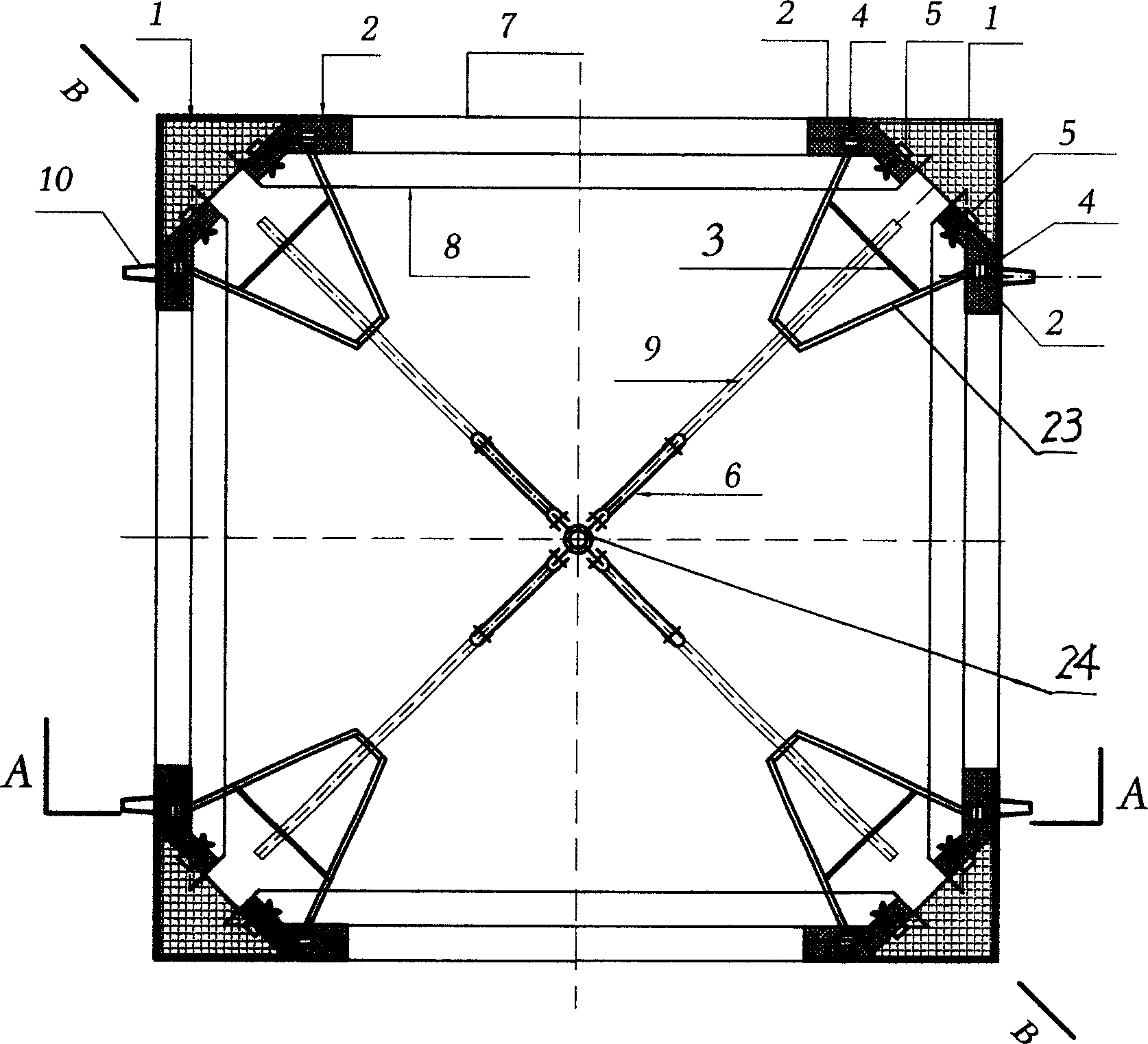

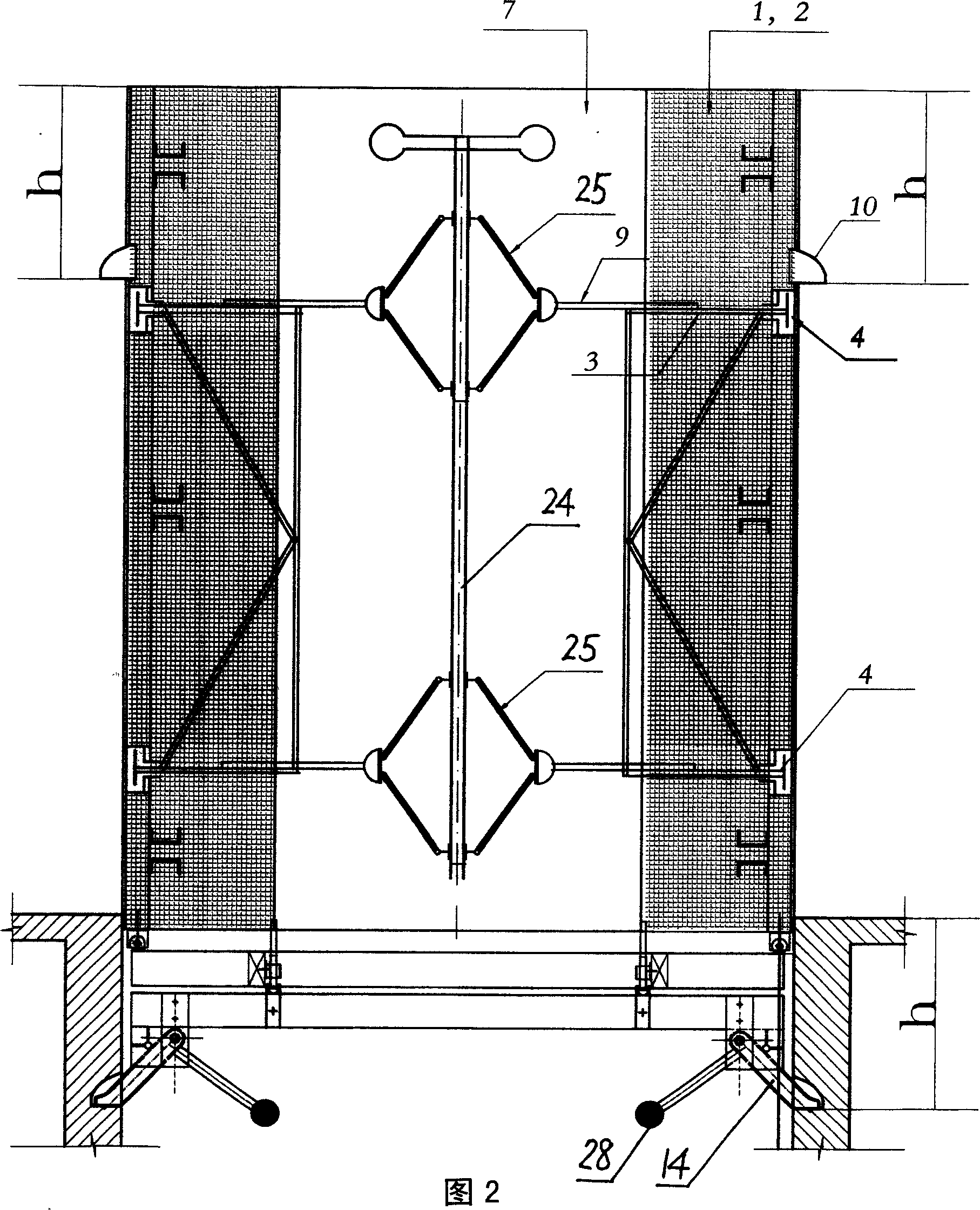

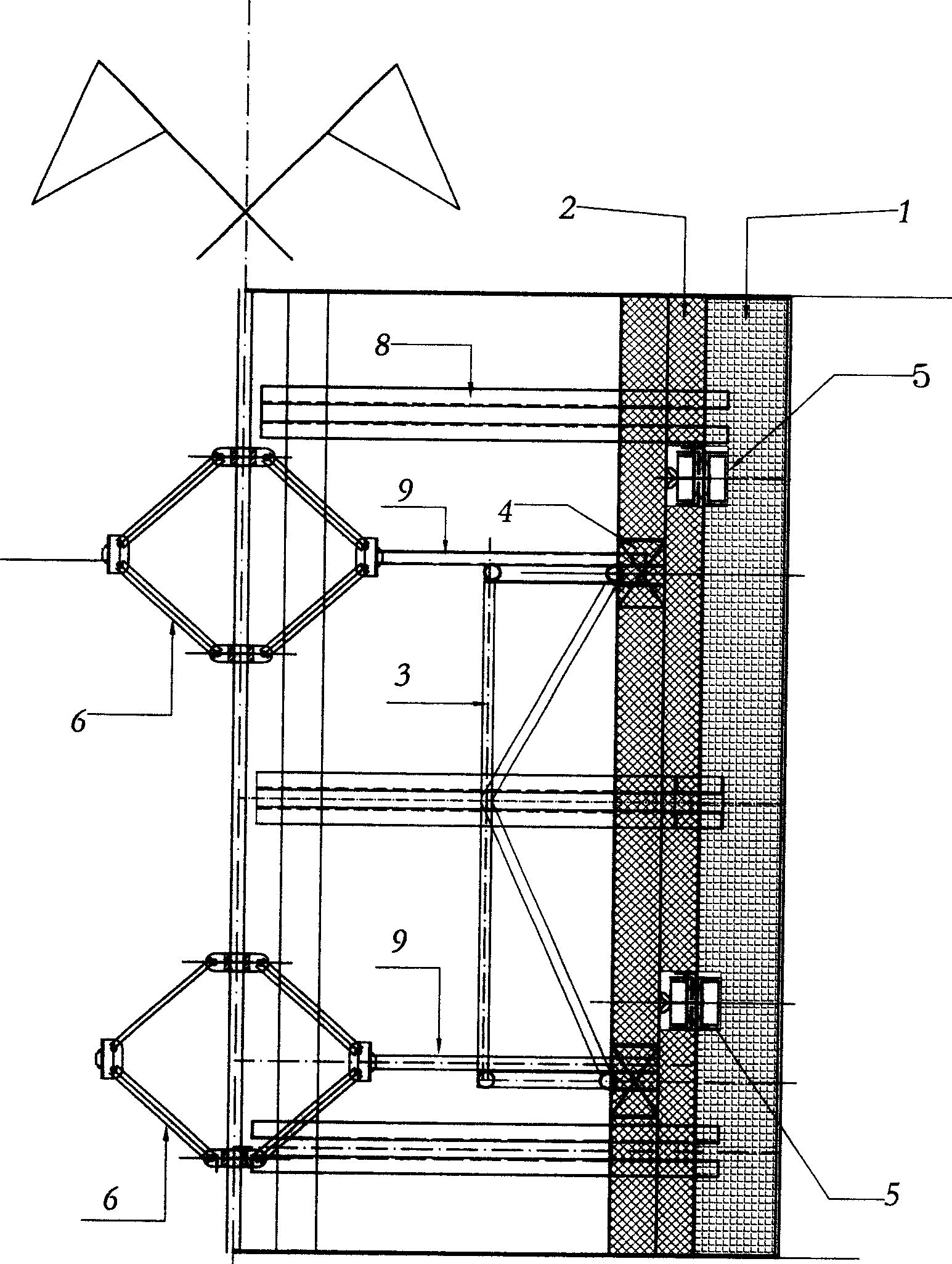

[0064] see figure 1 , 2, 3, the cylinder mold is formed by four sets of shaped corner combination mold bases and four non-stereotyped filling boards 7 drawn by back corrugated 8; Two shaped plates 2 of corner beams 5 at an angle of 135° are connected; the bottom edge of rigid corner mold 1 is connected with corner beam slider 5 in the horizontal direction, and the long side extension line of the corner beam slider is connected with the cylinder mold The diagonal line is at an angle of 45°; the formwork supporting frame is connected by a horizontal tie rod 9 with a replaceable length between the central retractable frame 6 and the force transmission frame 3, and the central retractable frame 6 and the horizont...

Embodiment 2

[0072] Embodiment 2: The force transmission frame 3 is in the shape of an isosceles triangle in the horizontal direction.

[0073] The working process of the present invention is described in detail:

[0074] 1. Tool type cylinder mold see Figure 1-13 :

[0075] The whole cylinder is composed of two major parts, the stereotyped assembly and the non-stereotyped part.

[0076] Shaped combination: It is composed of two combined units, one is the corner combined unit, including the following components: rigid corner mold 1, shaped plate 2, force transmission frame 3, shaped plate slider 4, corner beam slider 5, platform support There are six kinds of shaped parts altogether in the overturning mold box 10 in the reserved hole of the legs;

[0077] Unshaped parts include: filling board 7, back corrugated 8, horizontal tie rod 9 and other three parts. Unshaped parts are determined by the size of the shaft section.

[0078] see Figure 5 , The retractable function of the barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com