Measuring method and measurer for thickness of metallic thin strip

A measurement method and thickness measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as multiple calibration, metal failure, and the thickness of the measured object cannot be too thin, and achieve compact structure, rapid detection, and anti-interference. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

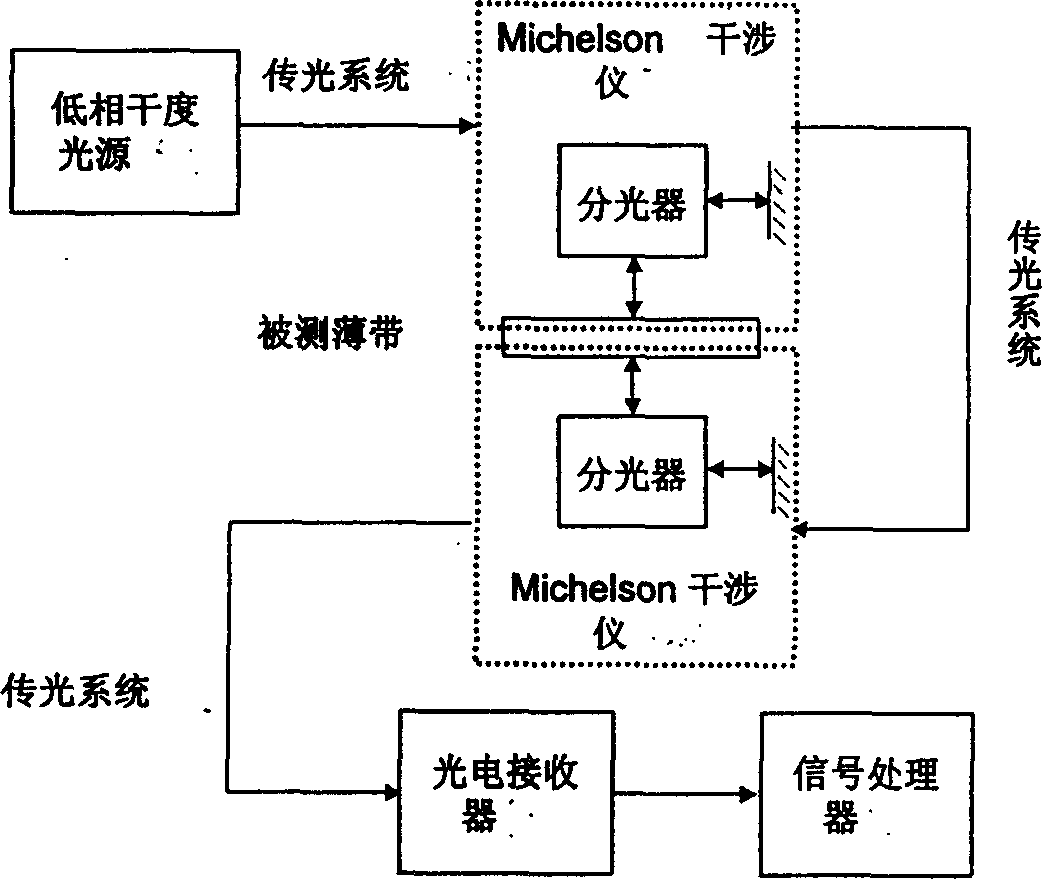

[0011] Such as figure 1 As shown, including low coherence light source, the first Michelson interferometer, the second Michelson interferometer, the first, second, third light transmission system, photoelectric receiver, signal processor; the first Michelson The interferometer and the second Michelson interferometer are placed on both sides of the measured metal strip, a low-coherence light source is irradiated to the beam splitter in the first Michelson interferometer through the first light transmission system, and the interfering light passes through the second The second optical transmission system is sent to the optical splitter in the second Michelson interferometer, and the interference light is connected to the signal processor through the third optical transmission system and the photoelectric receiver.

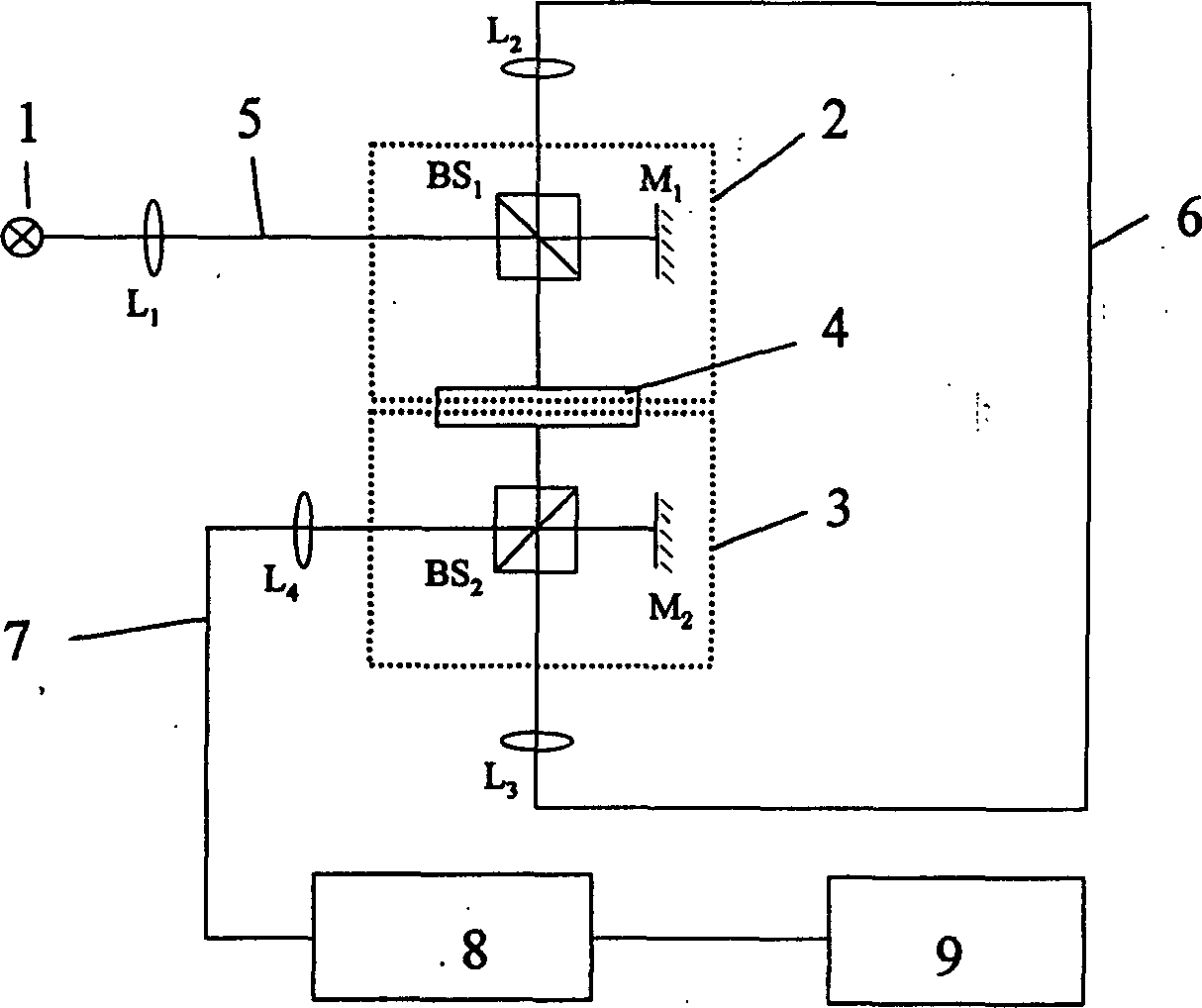

[0012] Such as figure 2 Shown, is an embodiment of the present invention, and this device comprises broadband light source 1, lens L 1 , optical fiber 5, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com