Self-lubricated free-cutting steel and method for producing same

A technology of free-cutting steel and production methods, applied in the field of iron and steel smelting, can solve problems such as physical damage of cutting tools, and achieve the effect of avoiding sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention is described in further detail below in conjunction with embodiment.

[0094] The embodiment is shown in Table 1, and the corresponding non-metallic typical composition is shown in Table 2 in the embodiment:

[0095] Metal component (weight percent wt%)+ *

C

mn

Si

S

Al

Ca

O

Example 1

0.46

1.56

0.26

0.32

0.006

0.0005

0.0048

Example 2

0.11

1.37

0.08

0.36

0.0046

0.0003

0.0050

Example 3

0.067

0.947

0.05

0.343

0.0011

0.001

0.0157

Example 4

0.40

1.2

0.35

0.08

0.01

0.004

0.0032

[0096] * The rest is iron and unavoidable impurities

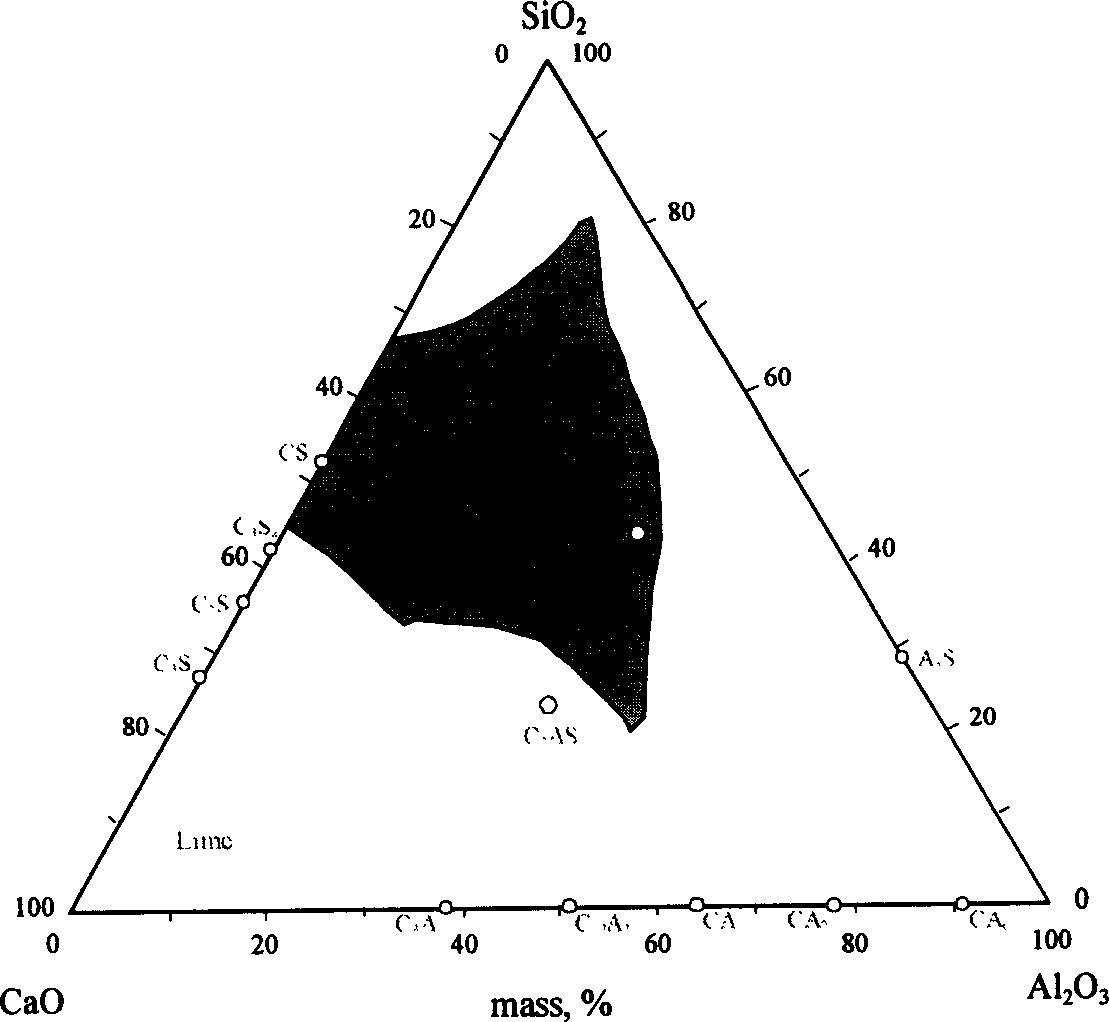

[0097] Typical inclusion components (wt%)

oxide inclusions

Sulfide inclusions

CaO

MnO

Al 2 o 3

SiO 2

MnS

CaS

Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com