Ternate plunger pump for high pressure industry

An industrial, high-pressure technology, applied in the direction of piston pumps, pumps, pumping devices for elastic fluids, etc., can solve problems such as bulky, bulky, and inconvenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

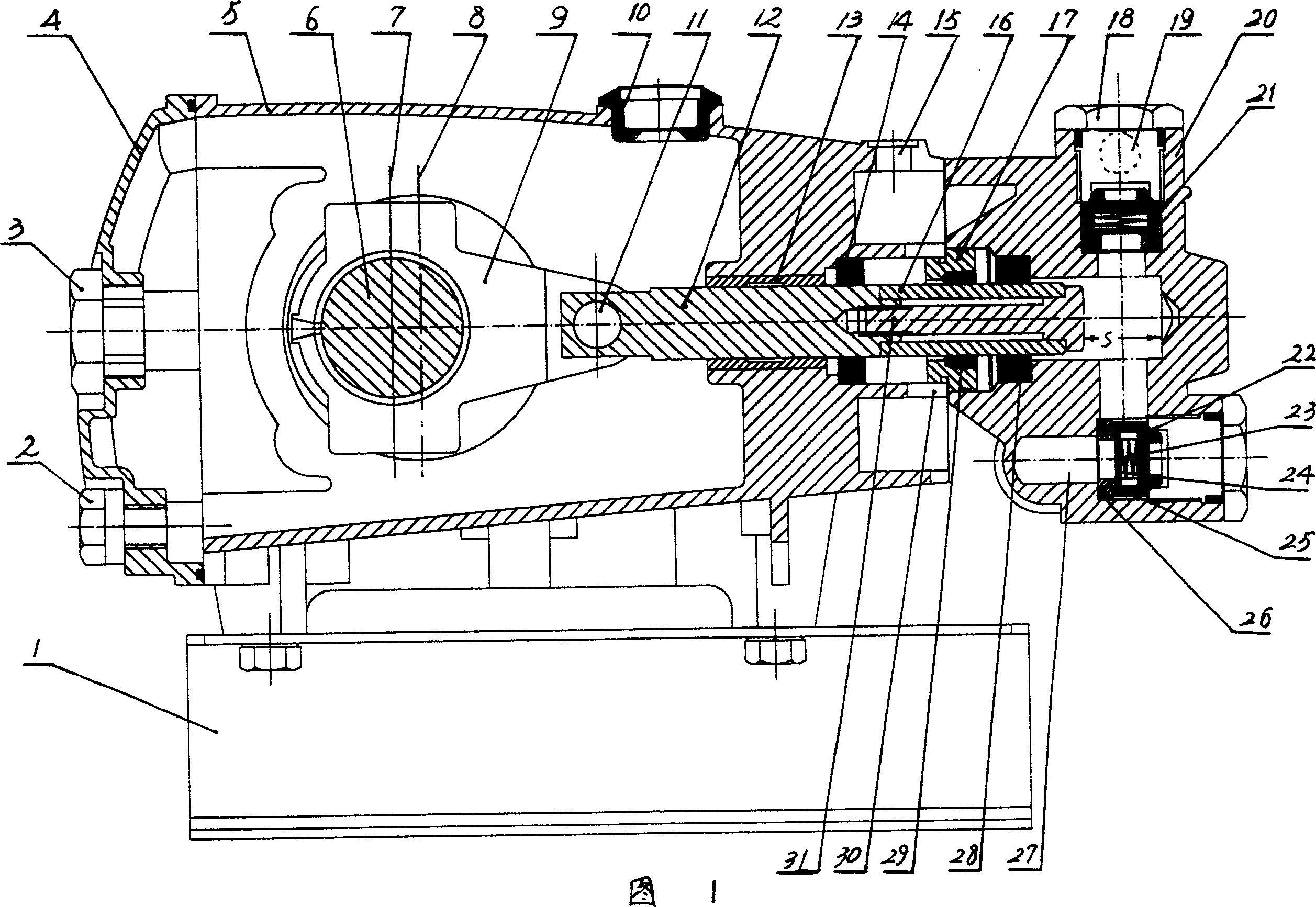

[0006] The invention discloses a triplex plunger pump, which is used for high-pressure (pressure can reach more than 300Mpa) industrial use (for industrial rust removal, such as rust removal on the surface of steel plates, washing of external wall pollutants, advertisements, stickers, wall "" psoriasis” etc., and unclogging the ducts). There is a casing 5, a base 1 can be installed under the casing, one end of the casing 5 is connected to an end cover 4, an oil level plug 3 and an oil drain screw 2 are made in the end cover, and a transmission mechanism is installed in the pump body, and the transmission mechanism is The crankshaft 6, connecting rod 9, etc. driven by power, the transmission mechanism drives the plunger 12, there is a pin 11, the casing has a fuel cap 10, the casing 5 is connected to the pump body 20, and the plunger 12 is located in the casing 5 and the pump body. In 20, the plunger 12 made of stainless steel is matched with a copper alloy cylinder liner 13, w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap