Method for casting wall embossing in situ using glass fiber reinforced plastic mould

A glass fiber reinforced plastic mold and on-site casting technology, which is applied to the field of on-site casting of glass fiber reinforced plastic molds for wall relief, can solve the problems of difficult installation and construction, short service life, easy cracks and water seepage, etc., and achieve the effect of small construction difficulty and fast effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

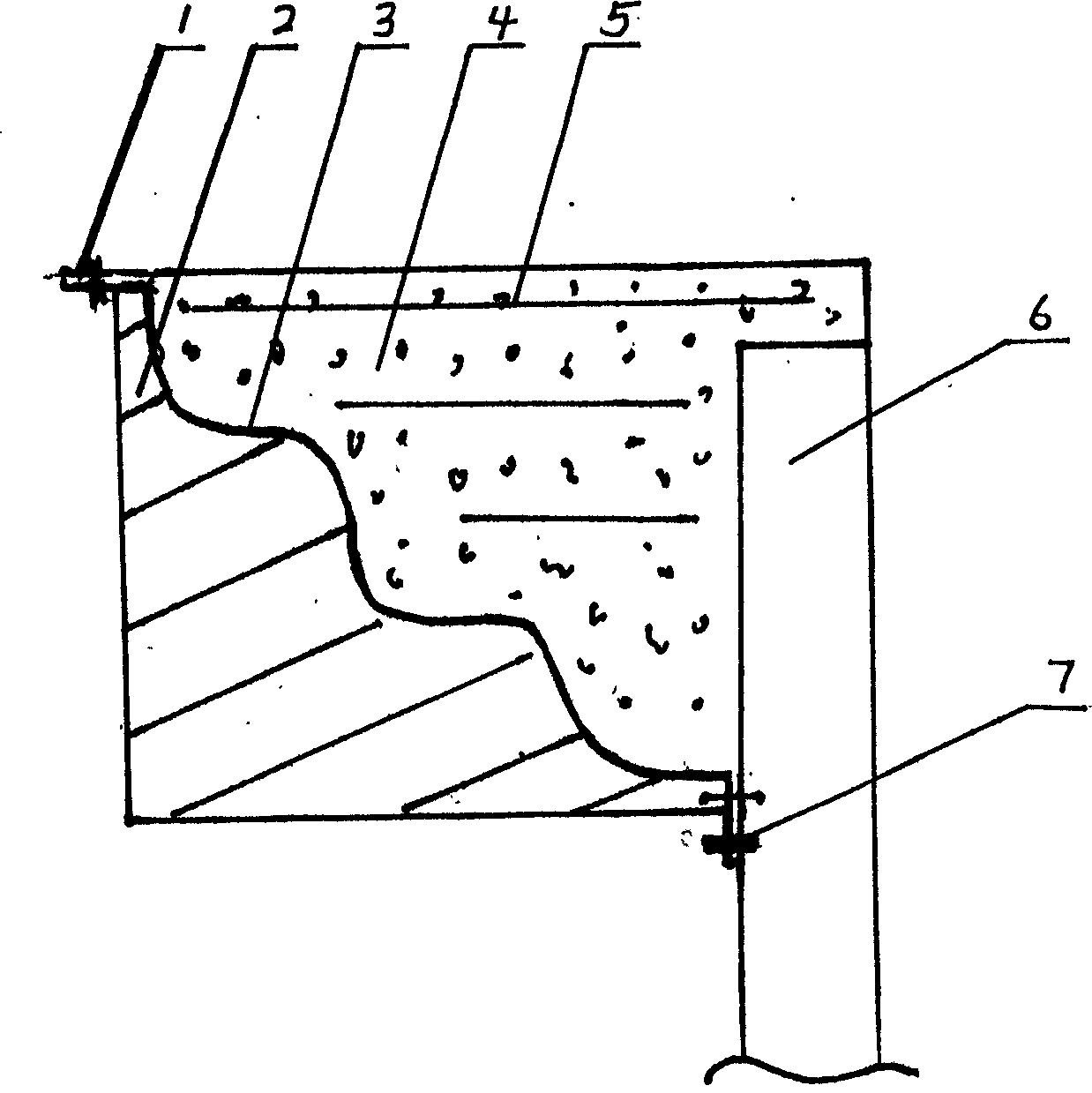

[0009] Such as figure 1 As shown, the present invention first prepares the glass fiber reinforced plastic mold (3) according to the pre-set eaves molding, and the outer side of the glass fiber reinforced plastic mold is provided with several strong ribs (2), and the installation lines connected with the wall body (6) are left on the two peripheries (1), then screw expansion screws (7) on the wall along the installation line of the FRP mold, fix the FRP mold on the wall with expansion screws, place steel bars (5) in the mold and in the wall, and cast Put cement concrete (4), after the cement concrete is solidified, take off the glass fiber reinforced plastic mold, demoulding molding. The invention connects the whole cement concrete eaves and the wall as a whole, so there is no crack, water seepage and long service life.

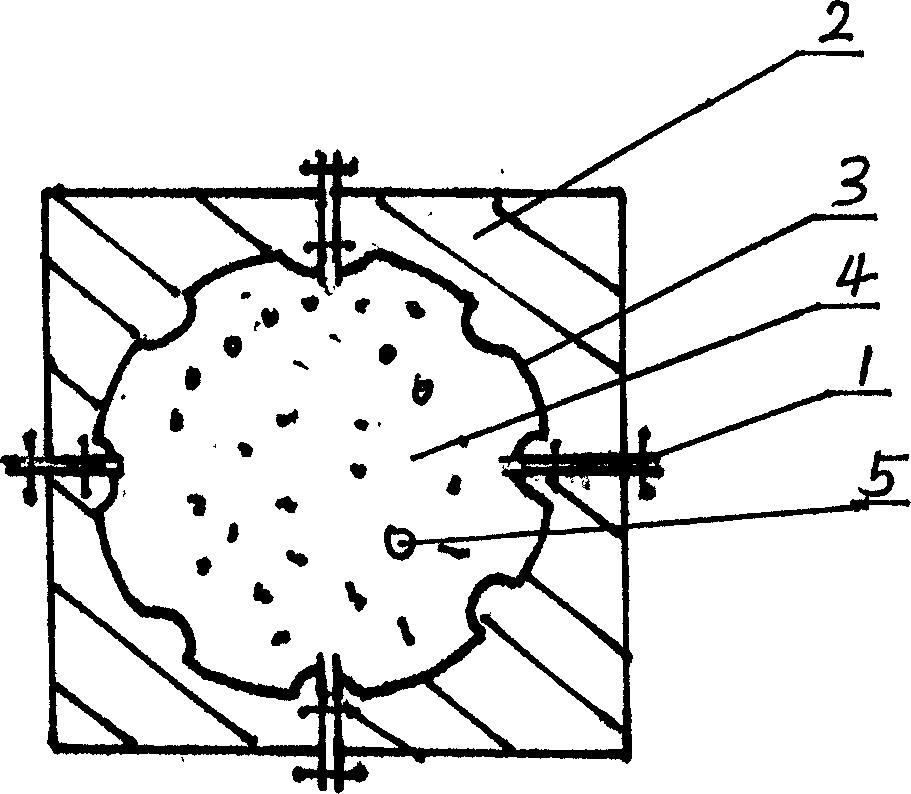

[0010] Such as figure 2 As shown, the preparation method of Roman column relief is to use four symmetrical glass fiber reinforced plastic molds (3) to pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com