Composite thermal insulation wallboard with no cold bridge

A composite thermal insulation and wall panel technology, applied in thermal insulation, building components, sound insulation, etc., can solve the problem that thermal insulation is difficult to adapt to the multi-functional and high-performance requirements of wall materials, and cannot meet construction needs, and achieves a wide range of market applications. , The effect of shortening the construction period and high strength of the board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

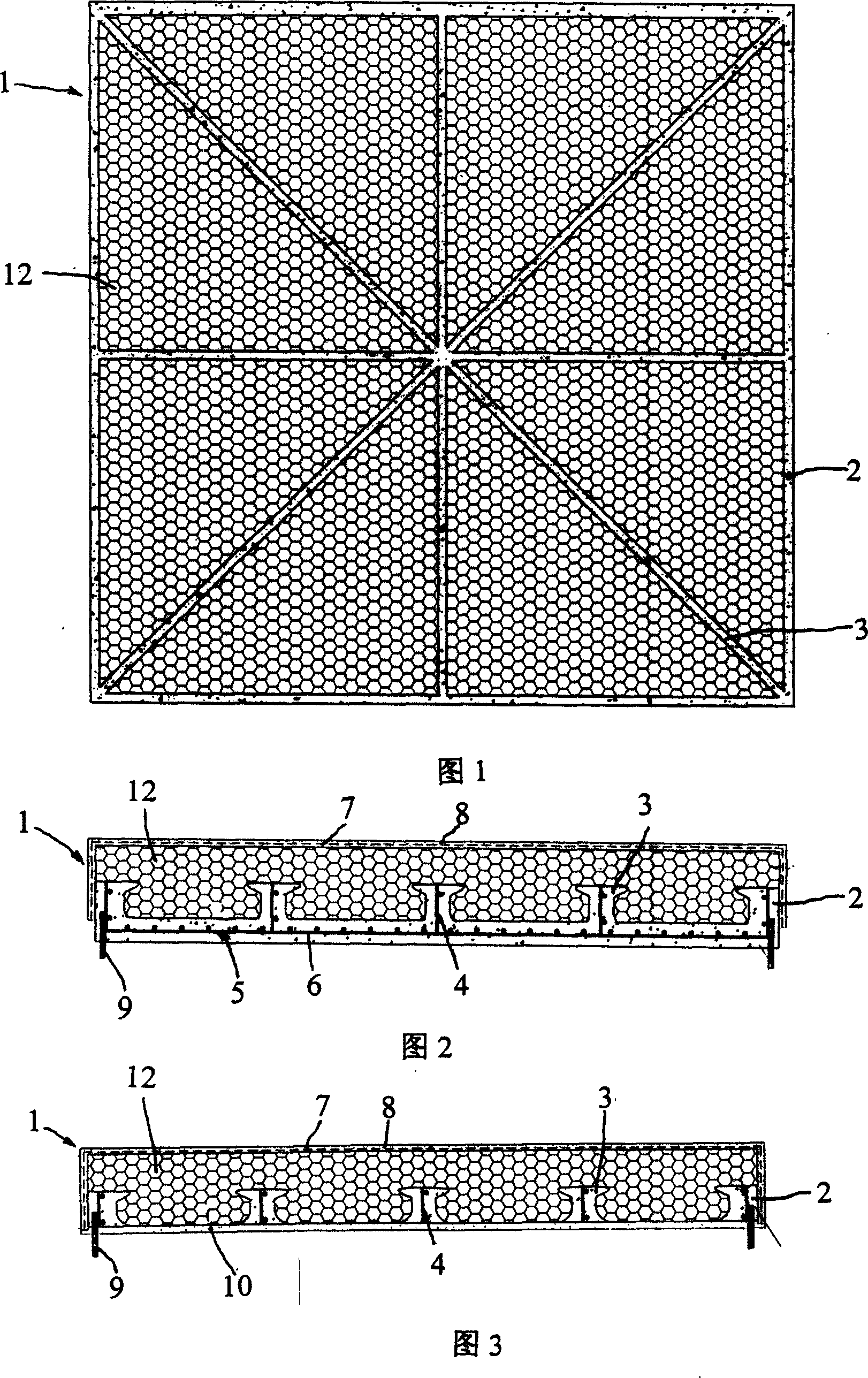

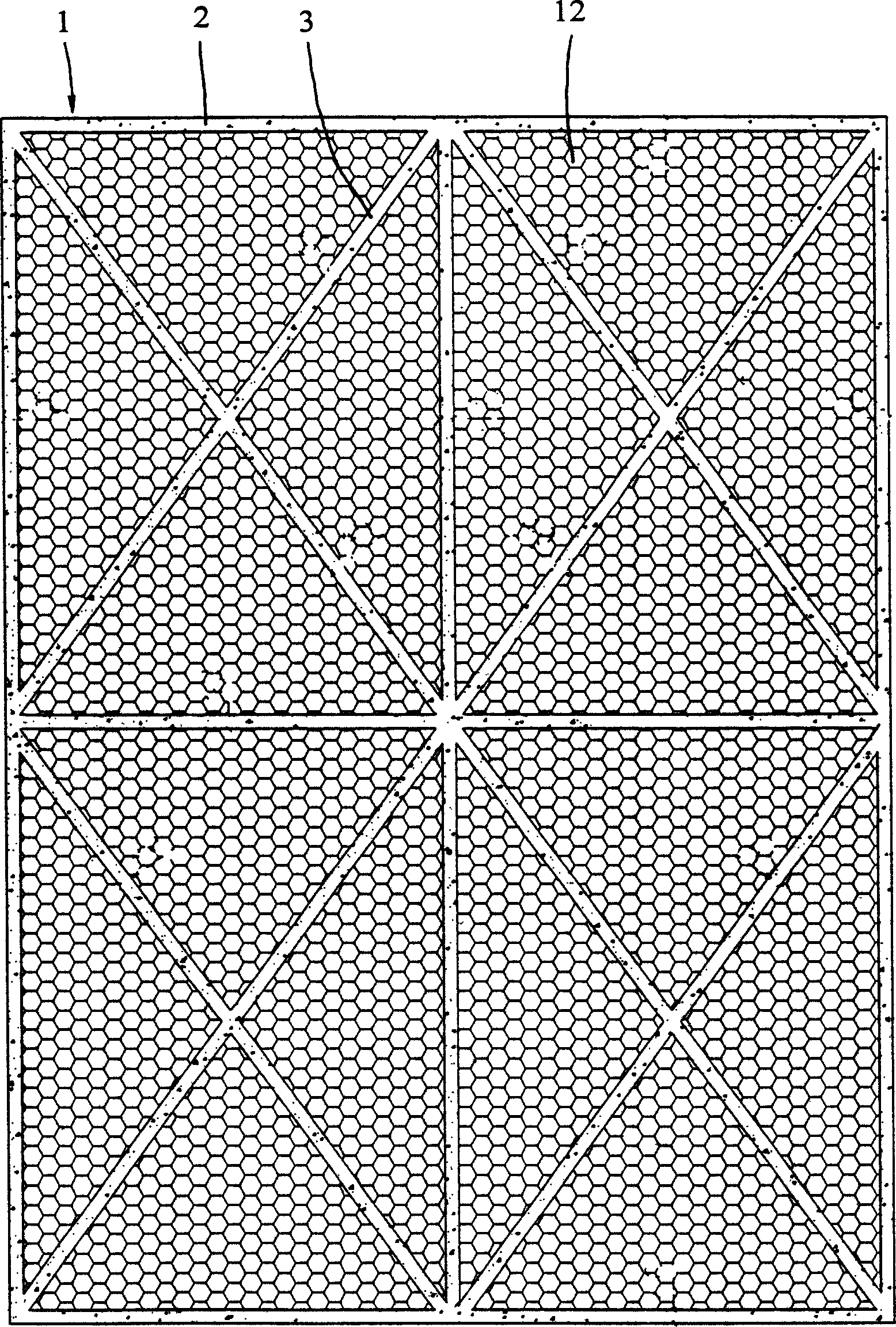

[0018] As shown in Fig. 1 and Fig. 2, the non-cold bridge composite thermal insulation wall panel of the present invention has a concrete frame 2 on the periphery of the panel body 1, the concrete frame 2 is rectangular, and a cross shape and an X shape are arranged in the concrete frame 2 Concrete ribs 3, and in the concrete frame 2 form a meter-shaped, the number of cross-shaped and X-shaped concrete ribs 3 can also be 2-4, or more. Between the concrete ribs 3 and on the upper surface of the concrete ribs 3 is provided with insulation material 12, the insulation material 12 adopted between the concrete ribs 3 and on the upper surface of the concrete ribs 3 is EPS insulation material or XPS insulation material or rock wool board or inorganic The sound insulation material or polystyrene particle mortar, the concrete frame 2 and each concrete rib 3 are provided with a steel grid frame 4 .

[0019] The cross-section of each rib of the concrete rib 3 is T-shaped, and the cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com