Detecting device of printed circuit board for mounting electronic element and figure poorness identification method

A technology for electronic component installation and printed circuit board, which is applied to printed circuit components, electrical components, measuring devices, etc., can solve the problems of time-consuming and the number of bad detection positions, etc., and achieve the effect of efficient discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

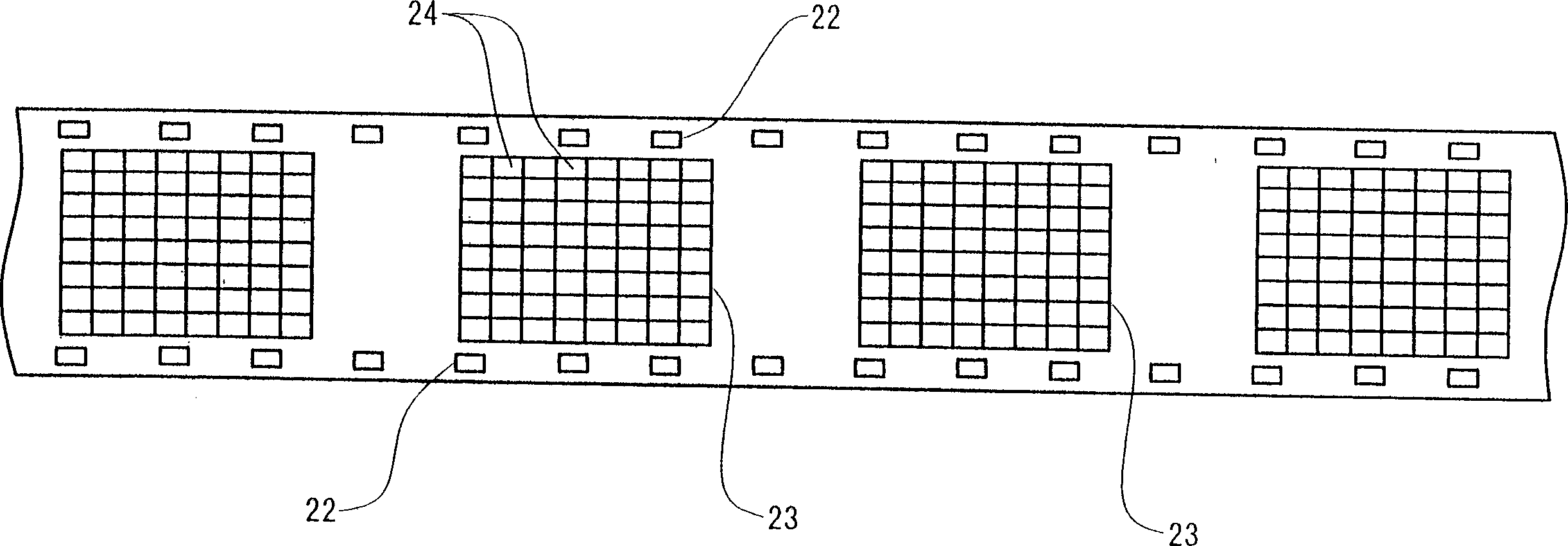

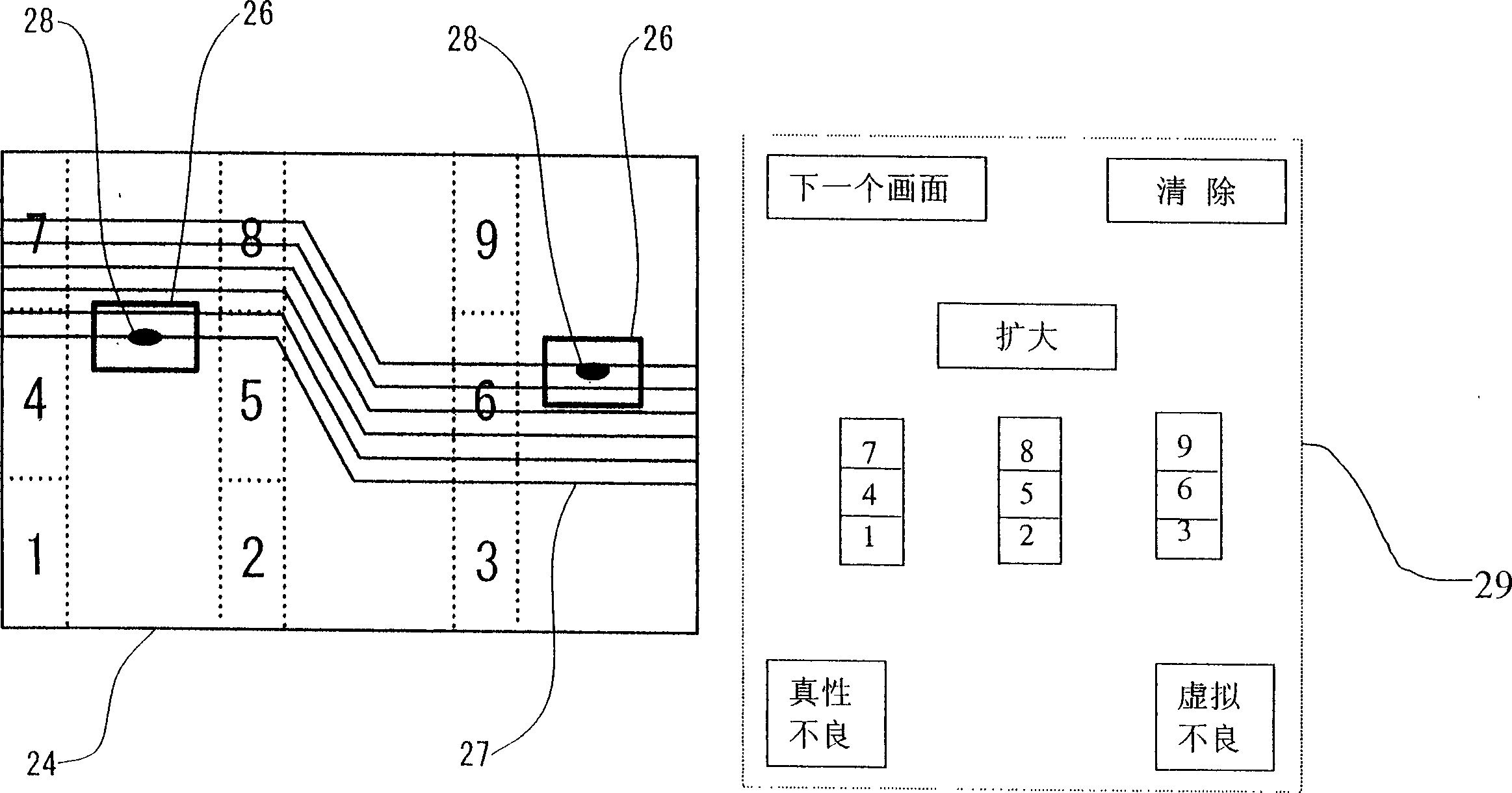

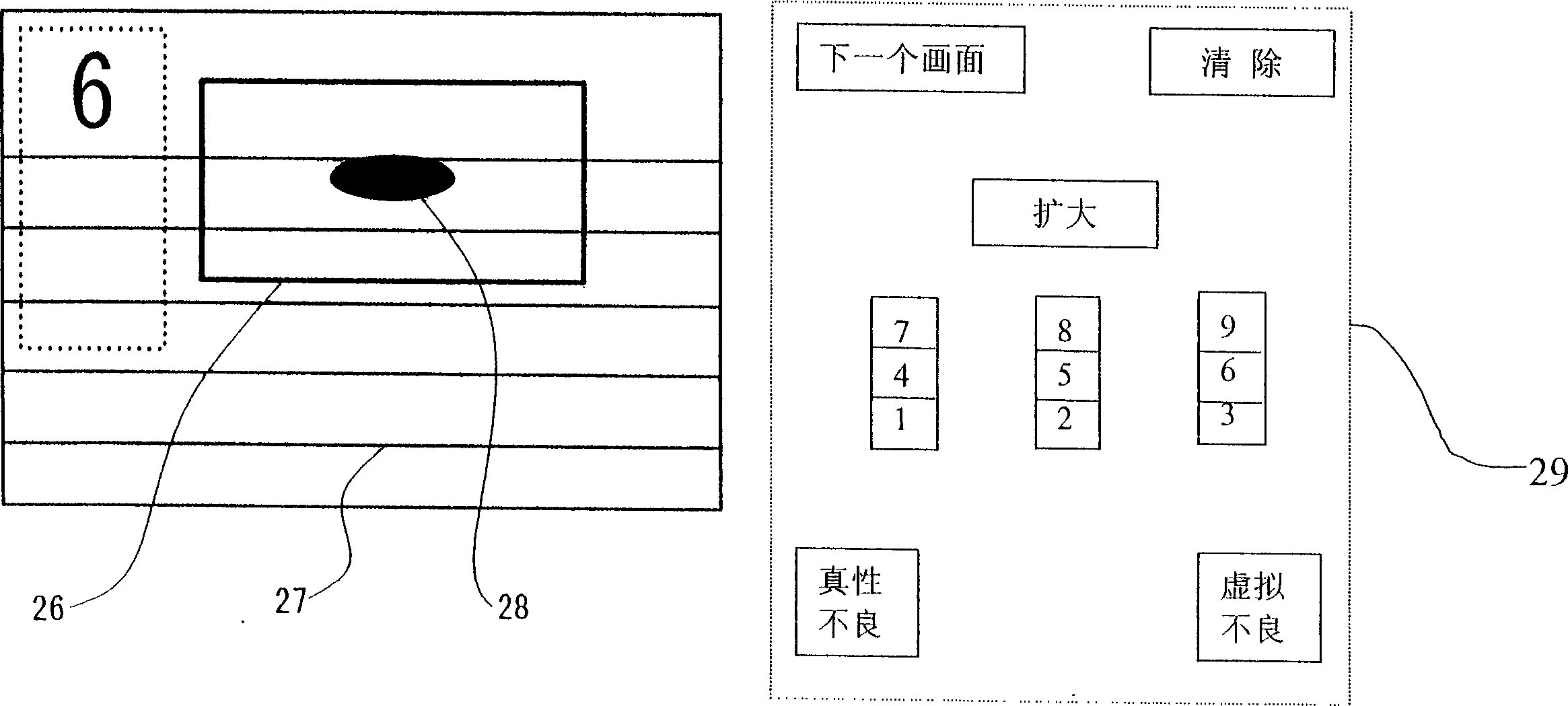

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Image 6It is a schematic diagram of a schematic configuration of a printed circuit board inspection device for electronic component mounting (hereinafter, simply referred to as "inspection device") as one embodiment of the present invention. As shown in the figure, this detection device consists of an unwinding device for unwinding printed circuit boards for electronic component mounting (hereinafter, the detection of film carrier tapes for electronic component mounting such as TAB tapes (hereinafter referred to as film carrier tapes) will be described as an example) 11. It is used to detect defects in the circuit diagram of each component arranged in the longitudinal direction of the tape; and the image processing device 12, through image processing, determines that the circuit diagram of each component in the film carrier tape is defective, and calculates the defective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com