Maintenance and inspection system and method

A management system and support system technology, applied in the direction of comprehensive factory control, electrical program control, instruments, etc., can solve problems such as trouble, and achieve the effect of improving quality, simplifying comprehensive use, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

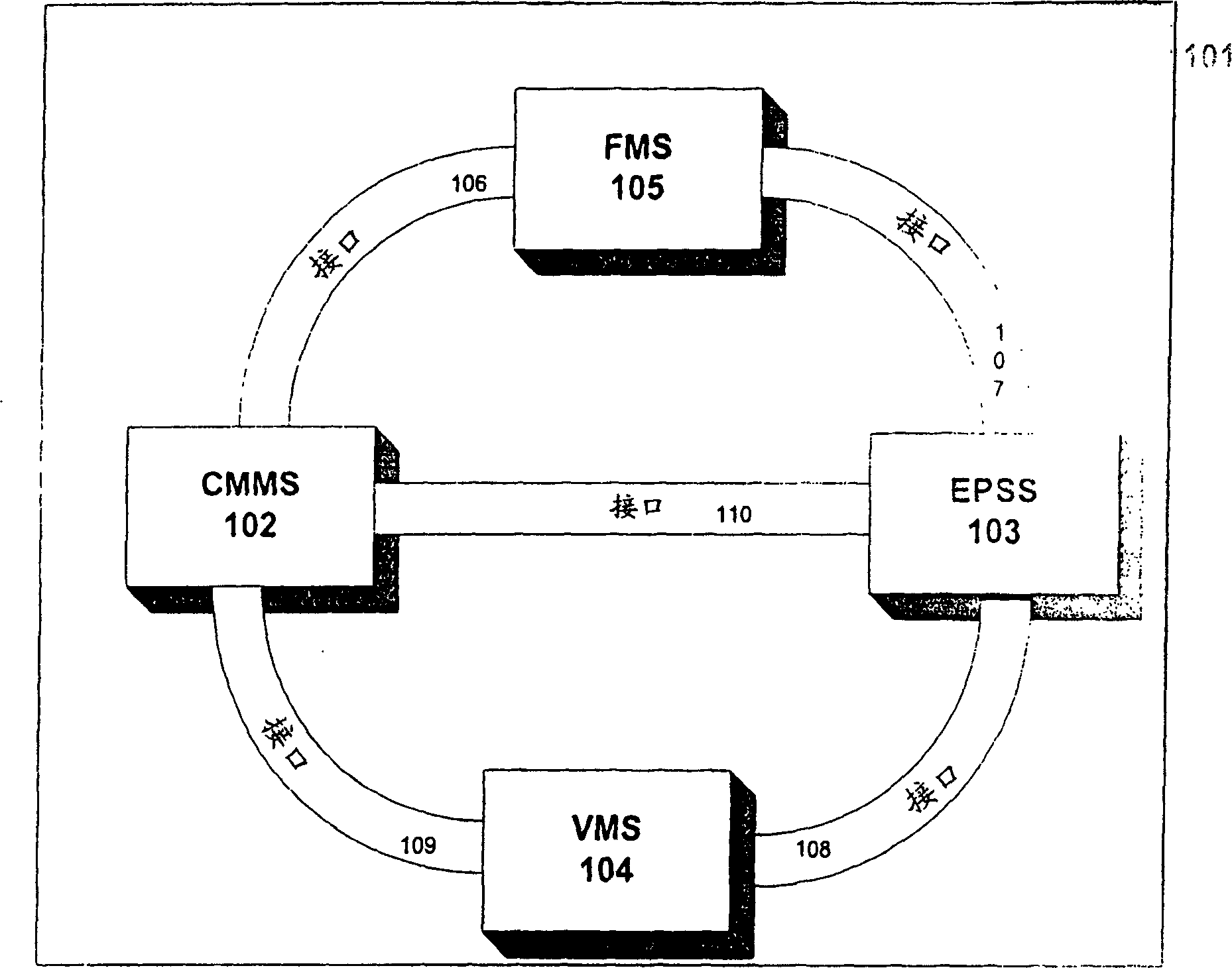

[0039] A discussion of the invention now proceeds with particular reference to the drawings and preferred embodiments. figure 1 A functional diagram of the maintenance management and inspection system of the present invention is shown. Host server 101 has installed and configured at least three software modules, including CMMS102, EPSS103 and VMS104. An optional fourth module is FMS104. CMMS / FMS interface 106, FMS / EPSS interface 107, EPSS / VMS interface 108, VMS / CMMS interface 109, and CMMS / EPSS interface 110 allow each module to interact and pass data between modules. Remote users install and configure client software on their mobile computers to access all host systems.

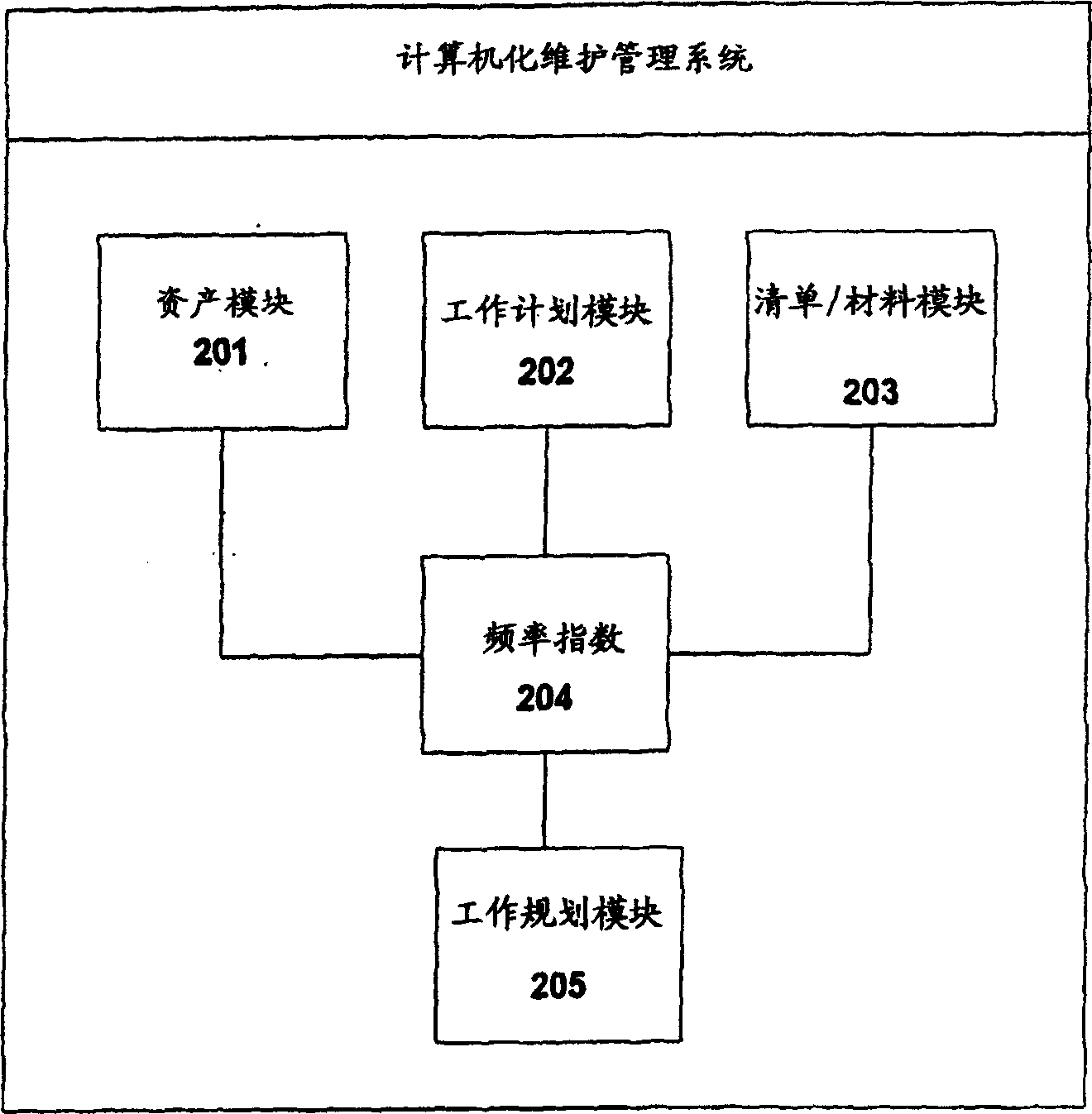

[0040] figure 2 A preferred embodiment of the computerized maintenance management system (CMMS) module of the present invention is shown. CMMS is used to manage and track maintenance and inspection work orders. To accomplish this, the CMMS consists of several host server-side subcomponents and several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com