Hydrophobic expanded pearlite for low temperature and its preparing method

A technology for expanding perlite and perlite, which is applied in the field of hydrophobic expanded perlite for low temperature and its preparation, and can solve the problems of increasing factory cost and affecting production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

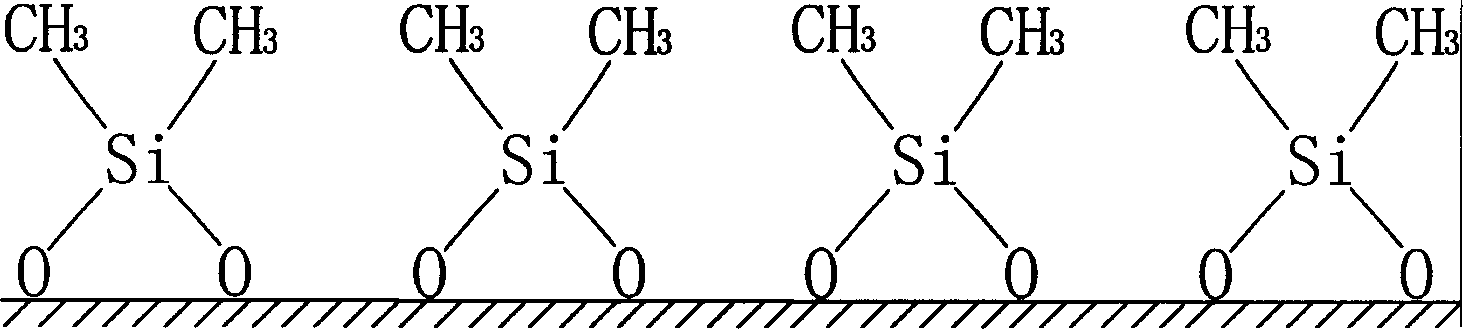

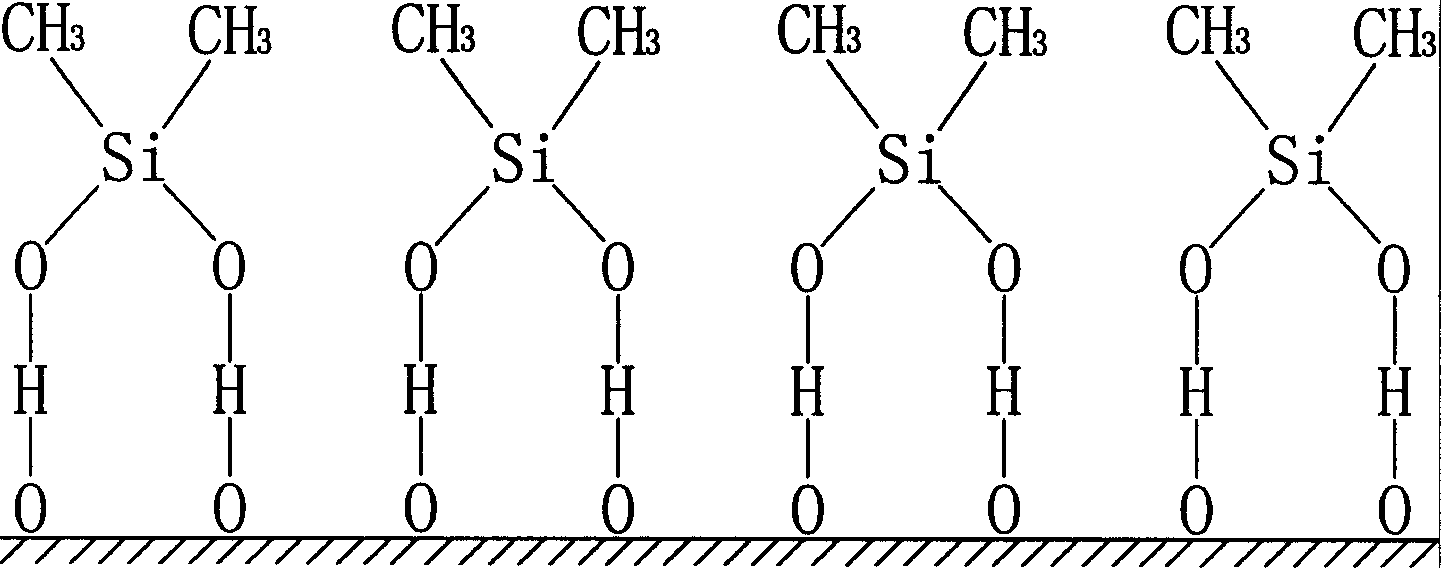

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, water-repellent agent: water=1: 5 (weight ratio) shape water-repellent agent solution, water-repellent agent solution: expanded perlite=1: 1 (weight ratio), mix and stir, dry and dehydrate to constant weight, Get expanded perlite, its water-repellent requirements can meet the technical indicators of French GTT company's water-repellent expanded perlite used in tank ships. Silicone oil is used as water repellent here.

Embodiment 2

[0032] Embodiment 2, water-repellent agent: water=1: 7 (weight ratio) forms water-repellent agent solution, water-repellent agent solution: expanded perlite=1.2: 1 (weight ratio), mix and stir, dry and dehydrate to reach constant weight, The water-repellent expanded perlite is obtained, and its water-repellent index can exceed the water-repellent technical index proposed by the French GTT company. Here, the water-repellent agent adopts silicone oil, or is an organic fat material.

Embodiment 3

[0033] Embodiment 3, water-repellent agent: water=1: 15 (weight ratio), form water-repellent agent solution, water-repellent agent solution: expanded perlite=1.4: 1 (weight ratio), mix and stir, dry and dehydrate to reach constant weight , to obtain hydrophobic expanded perlite, which has good hydrophobic performance and can be suitable for the needs of air separation equipment in the oxygen generator industry. Here, the water-repellent agent is silicone oil or an organic fat material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com