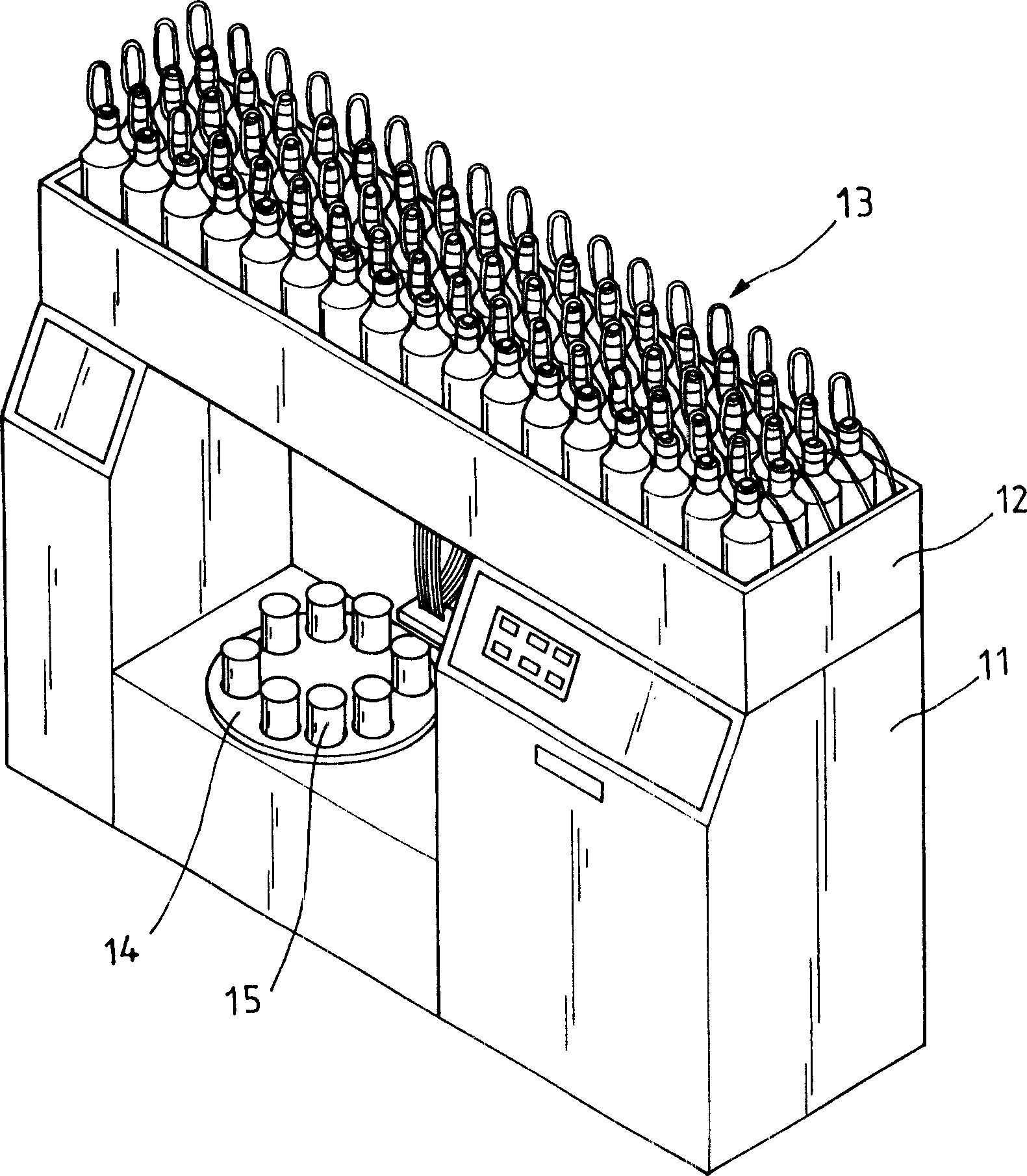

Direct-through automatic-stirring dropping liquid integrating apparatus

An automatic stirring and integrated device technology, which is applied in the direction of mass flow measurement device, textile material dyeing device, etc., can solve the problems of easy accumulation of liquid sediment, poor reproducibility, accumulation of dye or liquid sediment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

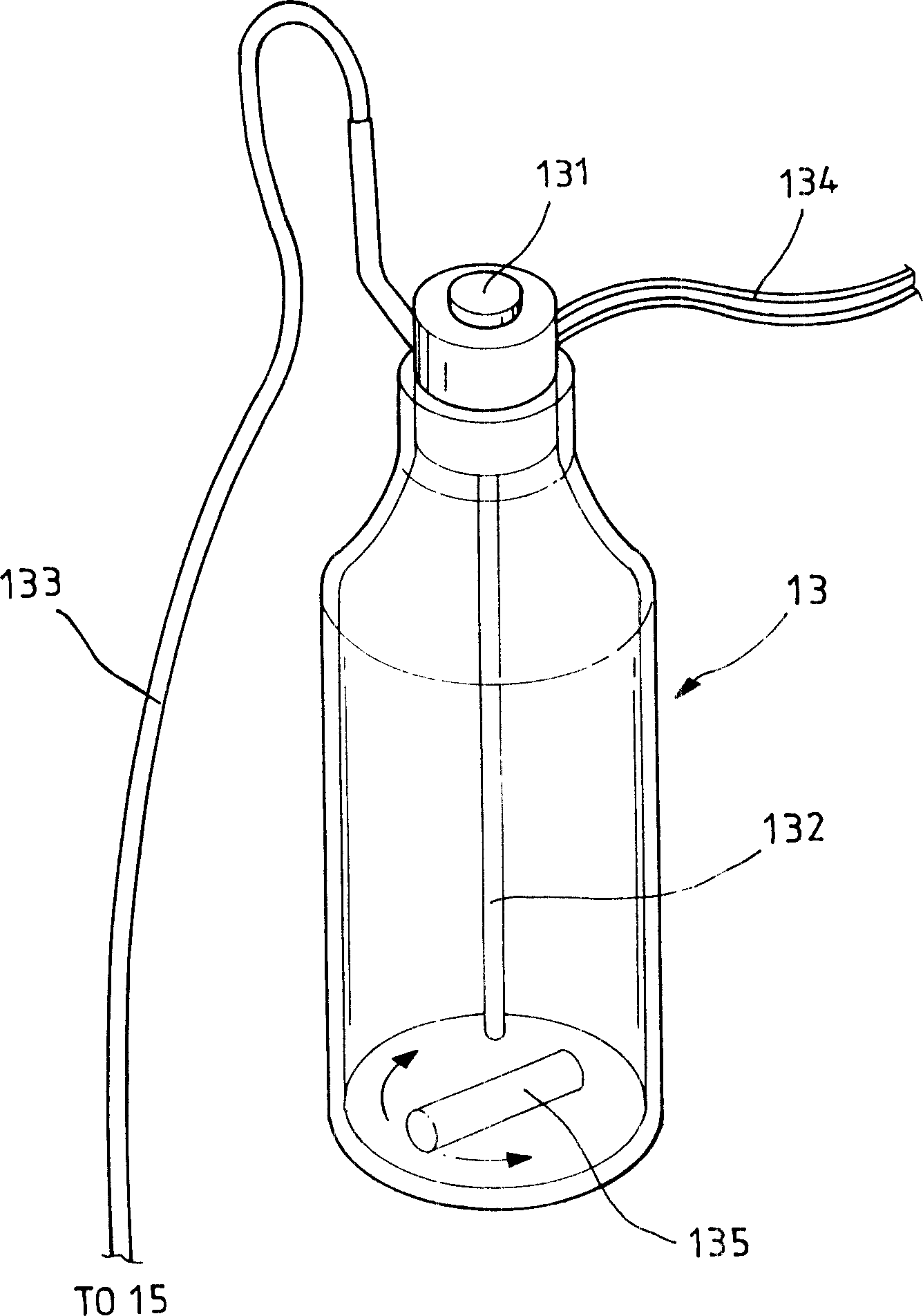

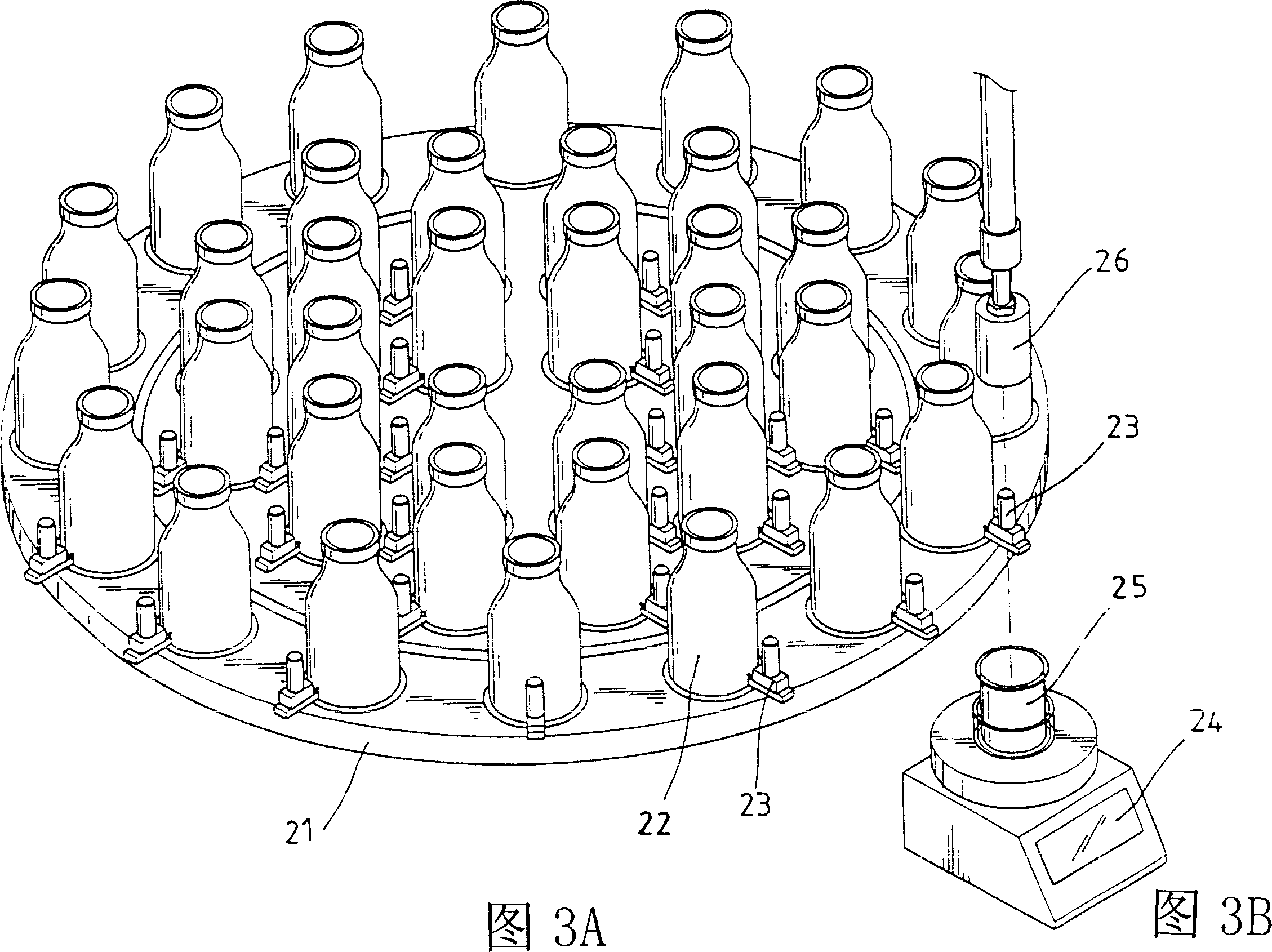

[0032] First, refer to Figure 5, Figure 6 , Figure 7 , Figure 8 , Figure 9As shown, the straight-through type automatic stirring and dripping integration device of the present invention includes: at least one raw material container 3, a round cover body 31 is provided below its bottom surface, and a stirring piece is provided at the bottom surface opening 32, and the bottom surface of the stirring piece 35 is connected to A flexible thin layer 33 is arranged between the round cover bodies 31, and the center of the flexible thin layer 33 is provided with an upright dropper 34 passing through the thin layer. 31, and at least one section of the outer circumference is provided with a magnetic conductor 341, and the sealing part 351 formed at the center of the stirring plate 35 is pressed on the top of the dropper 342; For the insertion of the round cover body 31, a shaft hole 42 is provided above the turntable 4, the bottom surface is open, and the periphery is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com