Static suspension rotor micro inertia sensor and its manufacturing method

A technology of micro-inertial sensor and electrostatic levitation, applied in the direction of rotating gyroscope, etc., can solve the problems of high equipment cost, poor side wall flatness, complicated process, etc., and achieve the effect of simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

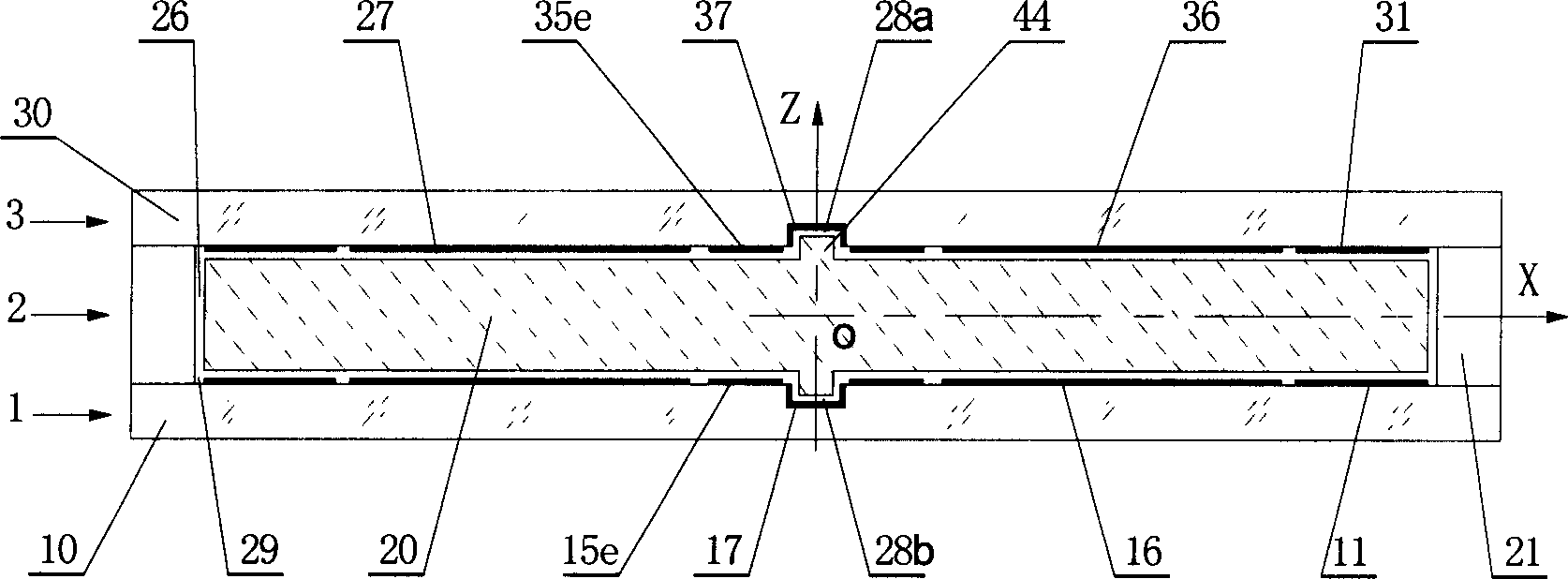

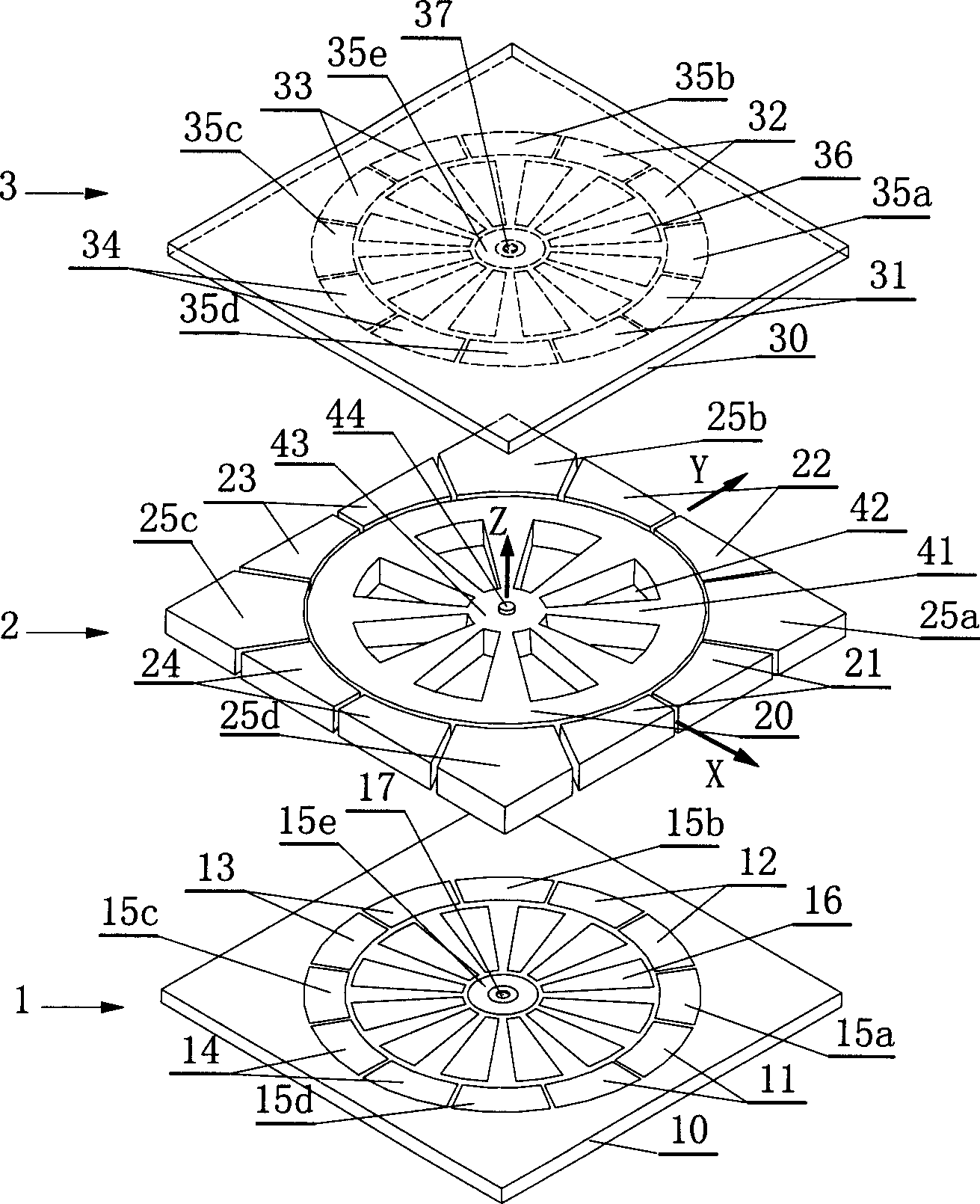

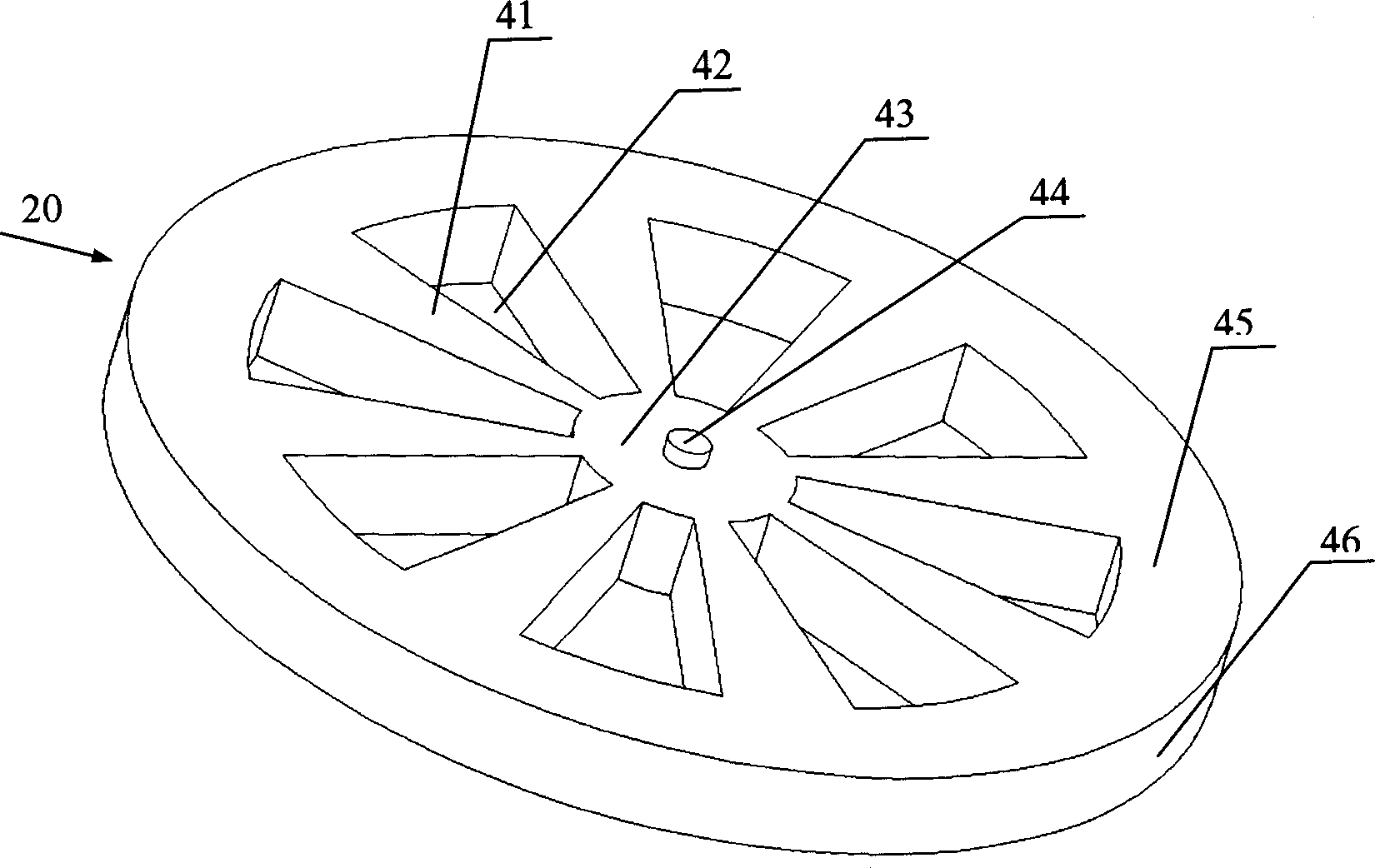

[0016] Such as figure 1 , figure 2 As shown, the present invention adopts a sandwich-type three-layer bonding structure, which is composed of a lower substrate layer 1 , an intermediate metal structure layer 2 and an upper substrate layer 3 . On the upper surface of the substrate 10 of the lower substrate layer 1, axial thin-film metal electrodes and leads are arranged, wherein the axial thin-film metal electrodes include axial suspension control electrode pairs 11, 13 arranged along the X-axis, and arranged along the Y-axis Axial levitation control electrode pairs 12, 14, common electrodes 15a-15e and rotation driven stator electrodes 16 whose number is a multiple of three; a stop pit 17 is also provided at the center of the lower substrate 10. The upper substrate layer 3 has the same structure as the lower substrate layer 1, and the lower bottom surface of the substrate 30 is also provided with axial suspension control electrode pairs 31, 33 arranged along the X axis, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com