Waste gas purifying and treating method and apparatus thereof

A technology of exhaust gas purification and treatment device, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high power of induced draft fan, inconvenient maintenance, large gas resistance, etc., and achieve good purification effect and structure. Simple, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

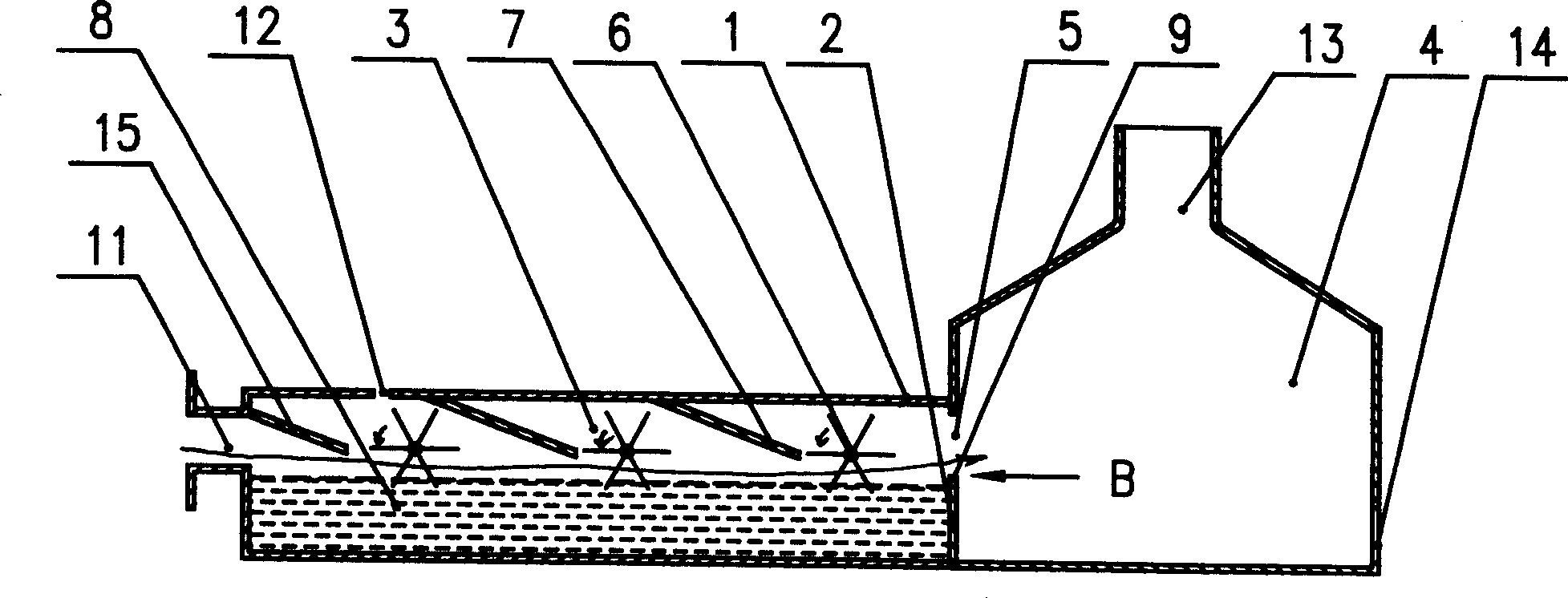

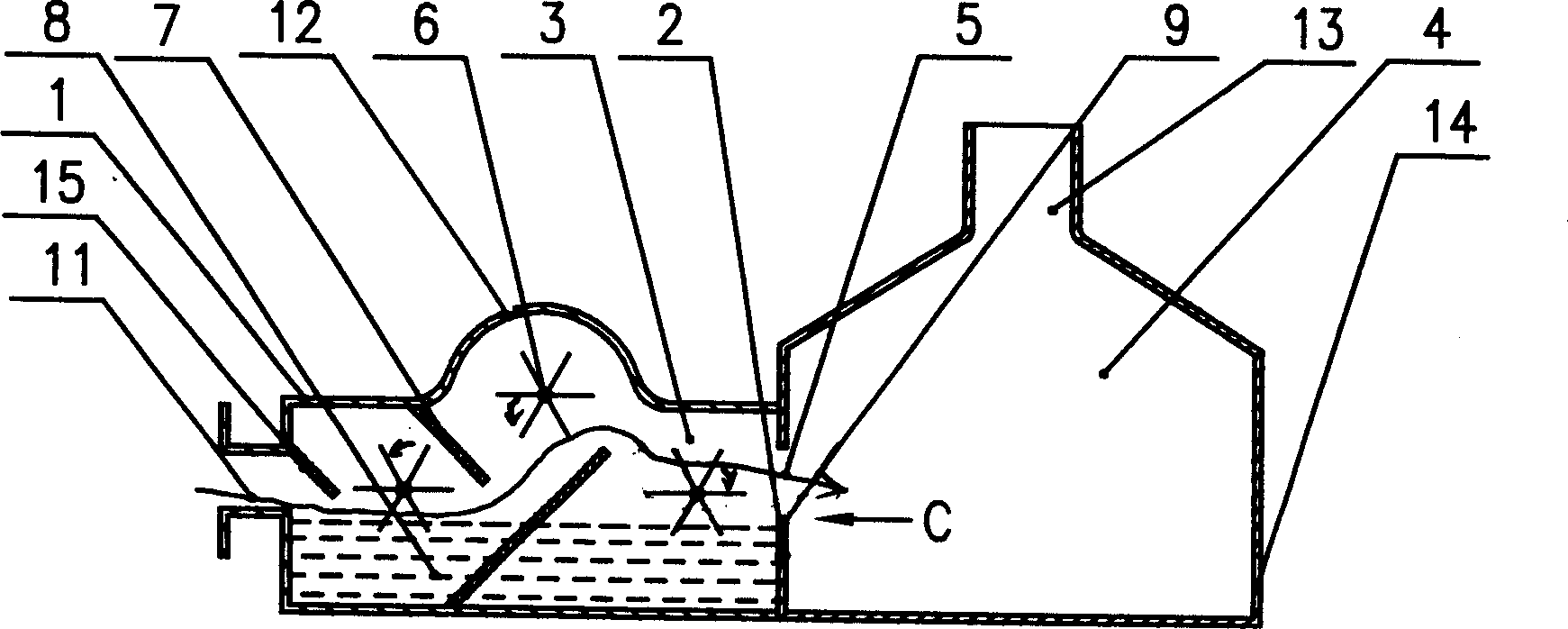

[0025] The exhaust gas flows into the airtight casing 1 through the air inlet 11, the impeller 6 in the casing 1 atomizes the purification liquid 8, the exhaust gas fully contacts with the atomized purification liquid 8, and the soluble toxic substances in the exhaust gas dissolve in the mist , after the gas flow is decelerated, liquid-gas separation is carried out, and the purified gas is discharged from the gas outlet 13.

[0026] There are two methods of liquid-gas separation, one is that after the gas flow is decelerated, the mist containing toxic substances settles naturally to achieve liquid-gas separation, and the other is to use a gas-liquid separator for liquid-gas separation.

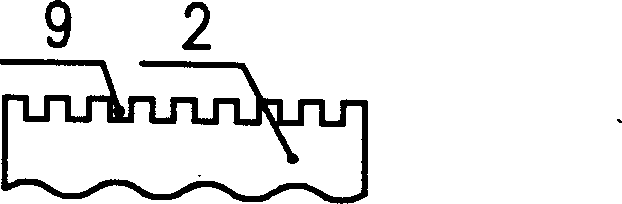

[0027] Such as figure 1 , 2 The shown first embodiment of the exhaust gas purification treatment device of the present invention has a closed housing or box body 1, and the housing or box body 1 is provided with a cavity that separates the inner cavity of the housing or box body 1 into exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com